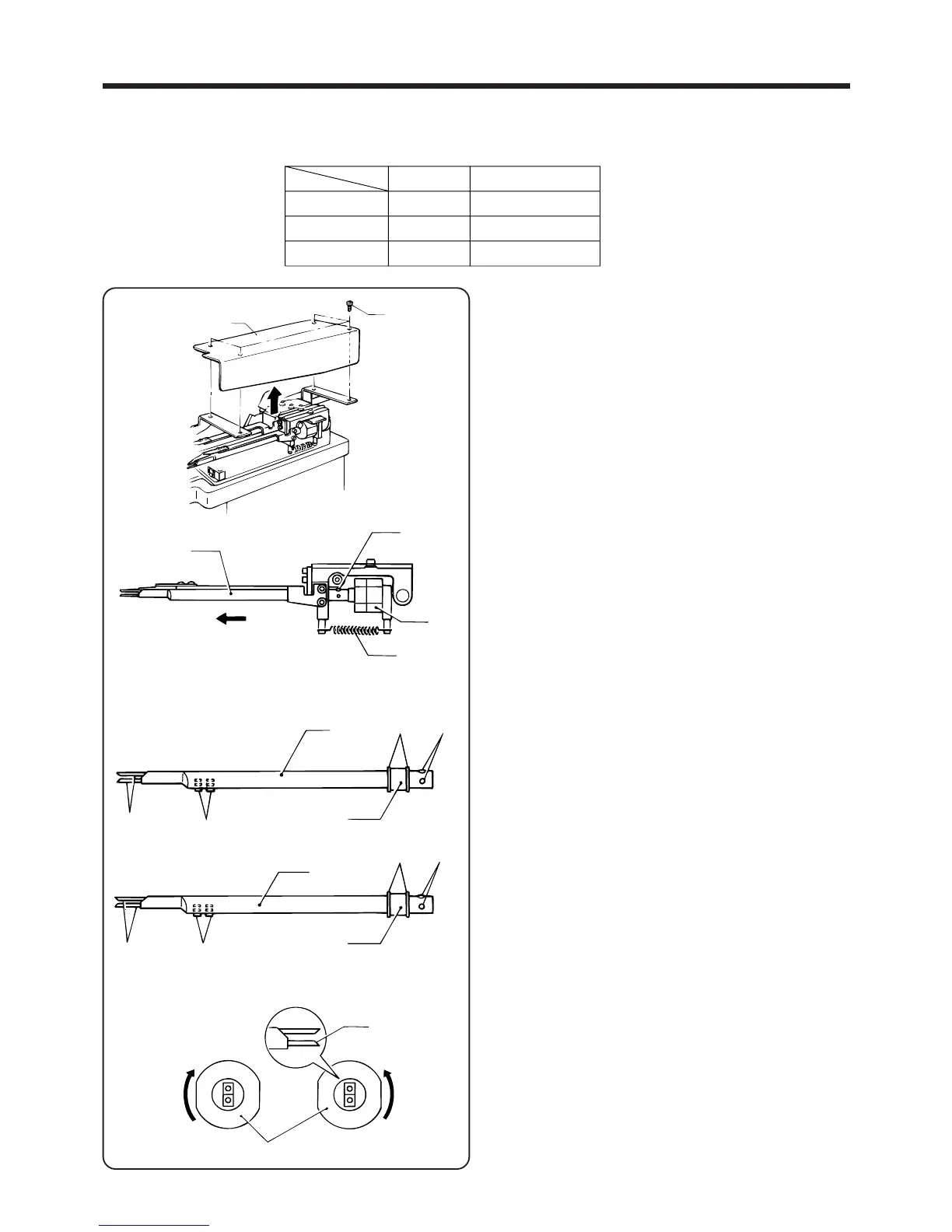

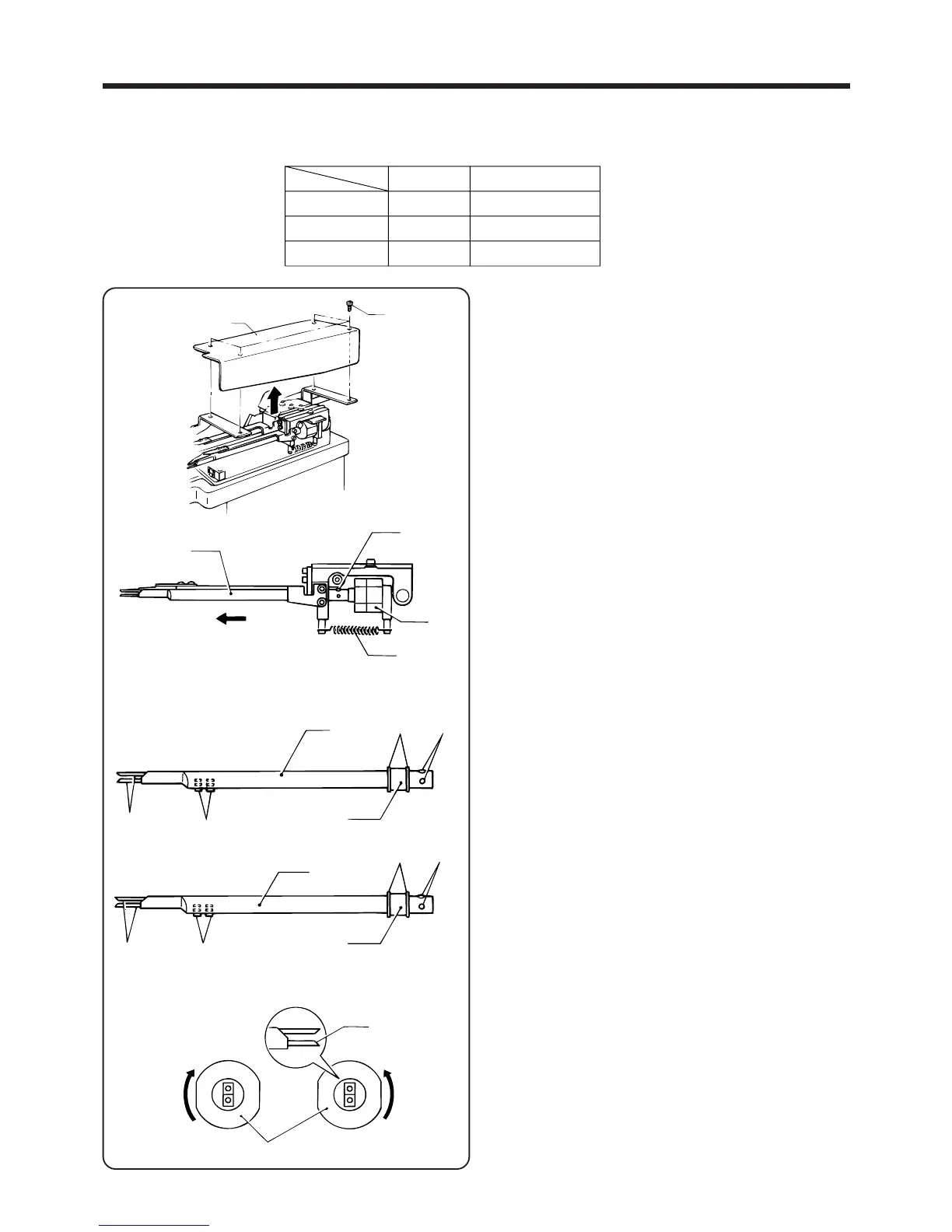

6. STANDARD ADJUSTMENT (MECHANISMS)

6-3-3. Replacing the fork bracket and fork shafts (L and S)

[When replacing the fork]

1. Remove the four screws q, and then remove the

feeder cover w.

2. Remove the springs e from the cylinder setting

base and from fork bracket F and fork bracket B.

NOTE: Be sure to use the proper tool to remove the

spring.

3. Remove the two screws t on the fork r.

4. Pull the fork r out from the rotary cylinder y.

NOTE: If the fork being replaced is an assembly,

proceed to step 7 below.

5. Loosen the two retaining rings u, the two fork

bushings i and the two set screws o, and then

remove fork shafts L and S !0 from the fork r.

6. Install the two retaining rings u and the fork bush

ings i to the new fork !1.

7. Secure the fork shafts L and S !00 with the two set

screws o so that the bevelled surfaces face inward.

8. Insert the new fork !1 into the rotary cylinder y.

9. Turn the rotary cylinder t as shown in the illustration

until it will not turn further, and then hold fork shafts

L and S !0 vertical beside each other, and install

them with the two set screws o.

10. Install the the springs e to cylinder setting base,

fork bracket F and fork bracket B.

11. Install the feeder cover w with the four screws q.

・Replace the fork in accordance with the thickness of the belt loops by referring to the table below.

―56―

BAS-705

r

t

y

e

r

u

i

t

o

!0

!0

o

!1

i

u

t

!0

!1

w

q

Thin material

Standard

Thick material

Clearance (mm)

1.8

2.6

3.2

Belt loop thickness (mm)

0.7〜1.3

1.1〜2.1

1.8〜2.7

Loading...

Loading...