2-95

Confidential

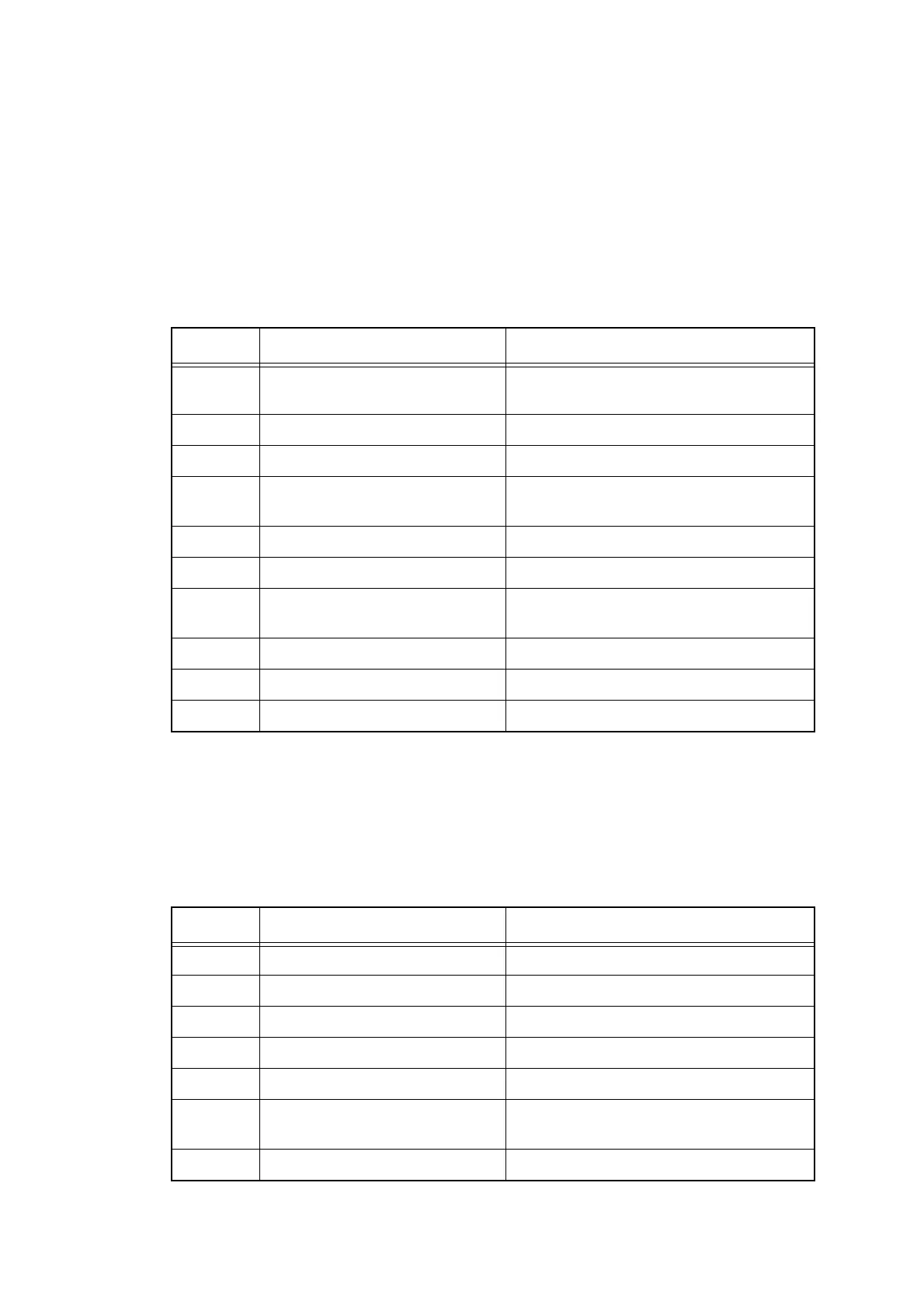

■ Paper jam at the eject section

< User Check >

- Check if the paper is loaded into each paper tray correctly.

- Turn back the paper loaded in each paper tray or change the orientation of the paper by 180°.

- Adjust each paper guide in accordance with the paper size.

- Check if too much paper is loaded in the tray.

- Check if the thickness of the paper is 60 to 105 g/m

2

.

- Fan the stack of paper well and reinsert the papers into each paper tray.

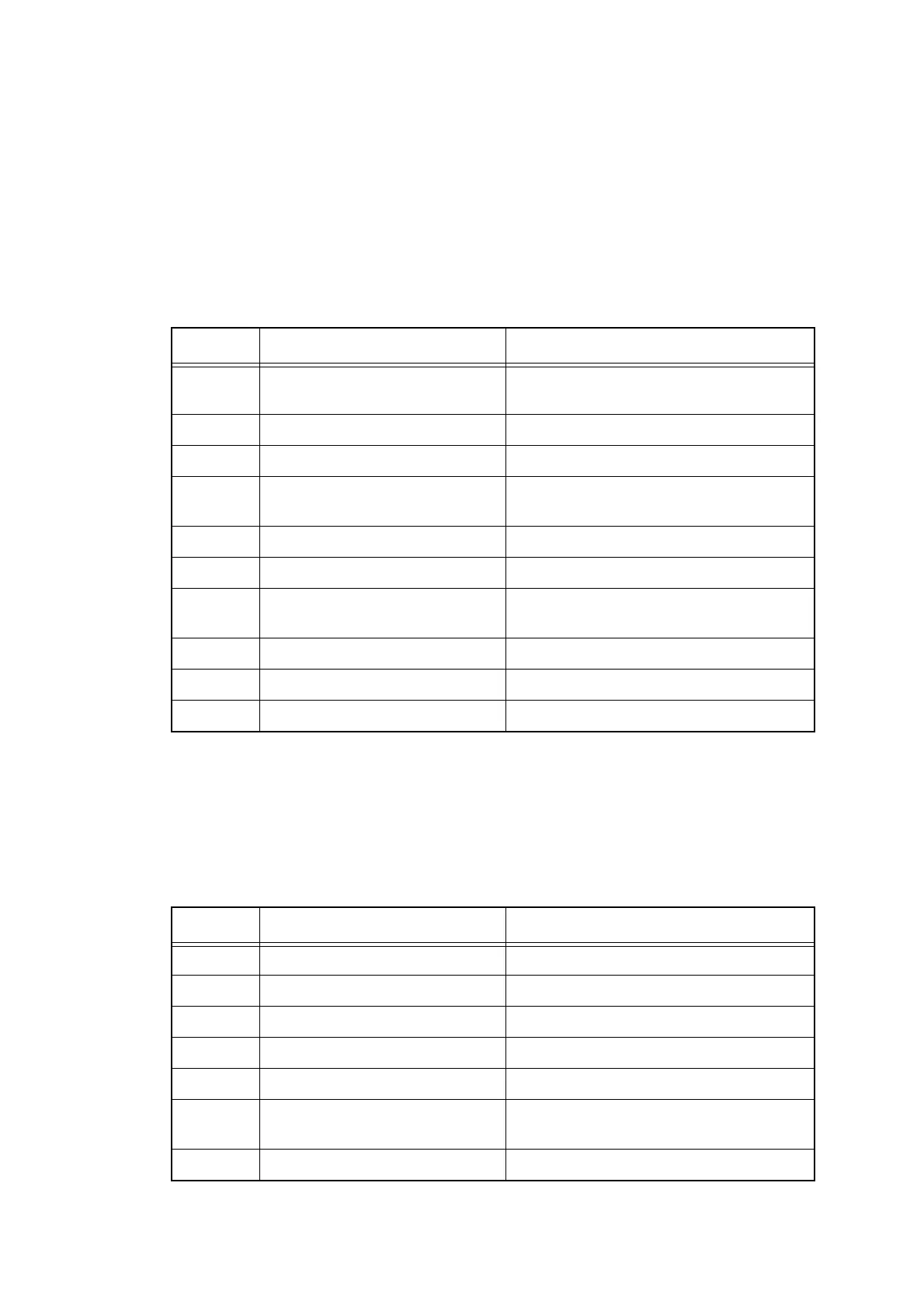

■ Paper jam at the duplex tray

< User Check >

- Turn back the paper loaded in each paper tray or change the orientation of the paper by 180°.

- Check if the thickness of the paper is 60 to 105 g/m

2

.

- Fan the stack of paper well and reinsert the papers into each paper tray.

Step Cause Remedy

1 Foreign object in back cover

section

Remove the foreign object.

2 Eject actuator coming off Re-assemble the eject actuator.

3 Fuser cover installation failure Re-assemble the fuser cover.

4 Connection failure of the eject

sensor PCB harness

Reconnect the eject sensor PCB harness.

5 Eject sensor failure Replace the eject sensor PCB ASSY.

6 Paper eject origin sensor failure Replace the paper eject origin sensor.

7 Main motor or process motor

failure

Replace the process drive unit.

8 Paper eject ASSY failure Replace the paper eject ASSY.

9 Fuser unit failure Replace the fuser unit.

10 Main PCB failure Replace the main PCB ASSY.

Step Cause Remedy

1 Foreign object in duplex path Remove the foreign object.

2 Eject actuator coming off Re-assemble the eject actuator.

3 Fuser cover installation failure Re-assemble the fuser cover.

4 Back cover failure Replace the back cover.

5 Duplex tray failure Replace the duplex tray.

6 Failure of duplex path of paper

tray 1

Replace the paper tray 1.

7 Main PCB failure Replace the main PCB ASSY.

Loading...

Loading...