Chapter 7

7-9

c. ADJUST

Performs adjustments and prints the adjustment and check patterns neccessary for adjusting the printer parts.

-PRINT PATTERN > NOZZLE 1

1.This nozzle check pattern is used during servicing and is printed in the single direction using a single path. It

is used to check for nozzles that are not injecting ink properly.

This pattern is printed on A4-size media in the landscape orientation.

The media type is optional.

-PRINT PATTERN > OPTICAL AXIS

This pattern is used to adjust the registration sensor oprical axis. For details,refer to "Disassembly/Adjustment"

> "Adjustment and Setup" > "Action to Take after Replacing the Carriage Unit or Multi Sensor".

Use photo glossy paper.

-PRINT PATTERN > LF TUNING

This pattern is used to adjust the cassette feed roller eccentricity. For details,refer to "Disassembly/Adjustment"

> "Adjustment and Setup" > "Action to Take after Replacing the Cassette Feed Roller HP Sensor or Cassette

Feed Roller Encoder".

Use photo glossy paper.

-HEAD ADJ.

This mode allows you to set of reset the registration adjustment values of individual heads.

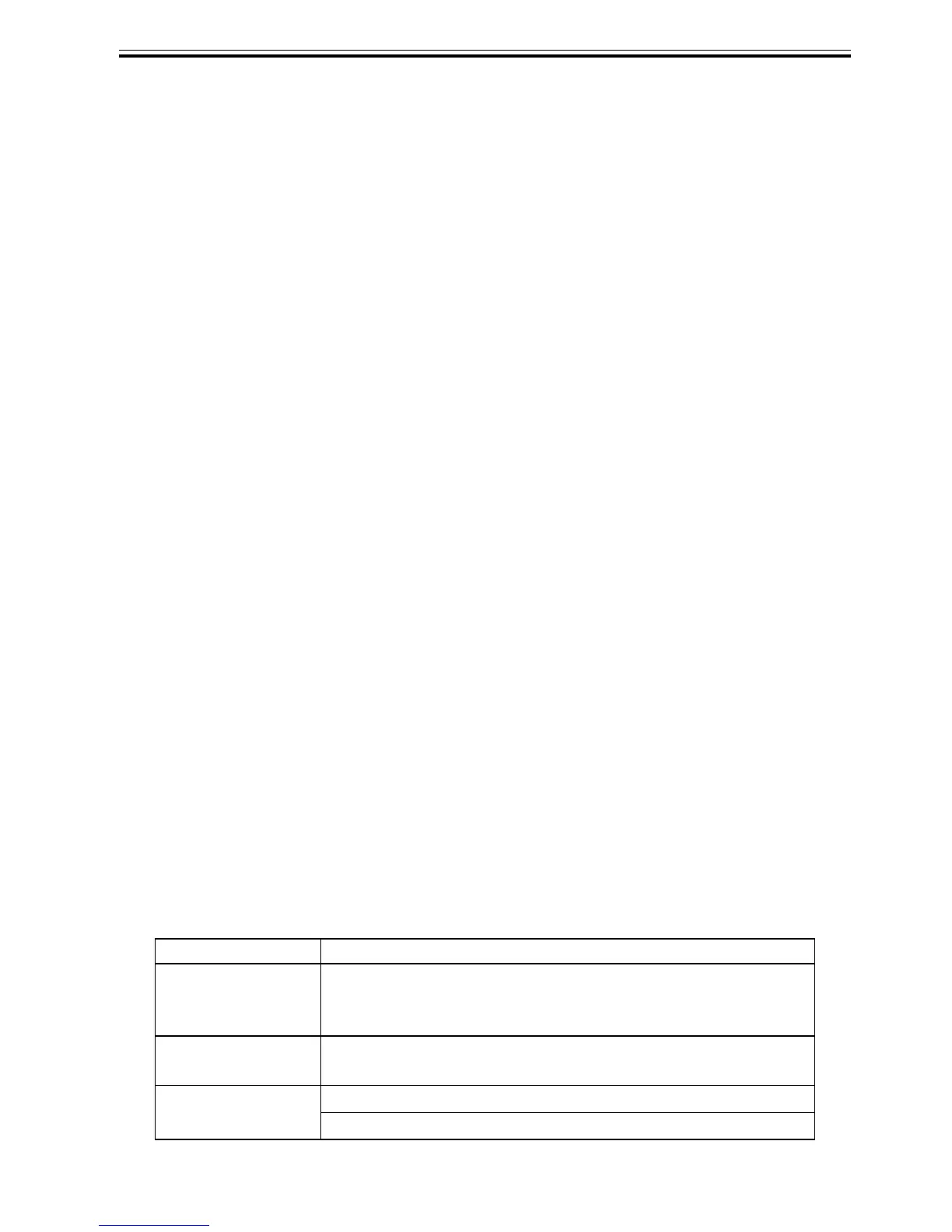

T-7-7

16 (Not Used) -

17 Roll Media Sensor 0:Sensor ON ,1:Sensor OFF

18 Roll Cam Sensor 0:Sensor ON ,1:Sensor OFF

19 (Not Used) -

20 (Not Used) -

21 (Not Used) -

22 (Not Used)

-

23 (Not Used)

-

24 (Not Used)

-

25 (Not Used)

-

26 Roll unit detection 0:Roll unit not detected, 1:Roll unit detected

27 Cutter unit detection 0:Cutter unit no detected, 1:Cutter unit detected

28 (Not Used)

-

29 (Not Used)

-

30 (Not Used)

-

31 (Not Used)

-

32 (Not Used)

-

Display Description

MANUAL HEAD

ADJ

Prints the manual head adjustment pattern.

DETAIL:Fine adjustment

BASIC:Simple adjustment

ADJ. SETTING Allows you to enter any registration adjustment value within the

range of-127-to+127.

RESET SETTING Resets the registration adjustment values.

Adjustment values A1 to F* are reset(to zeros).

Displa

y

positi

on

Sensor name LCD display contents

Loading...

Loading...