41

The SPECIAL FUNCTIONS (Fx) related to the MMA process correspond as follows to those on the wire feeder:

Special function PARAMETER DISPLAY Screen - A

PARAMETER DISPLAY Screen - V

Default Range

HOT START Hot 50 (0 - 100)

ARC FORCE ArC 50 (0 - 100)

WARNING:

• It is possible to access editing of the SPECIAL FUNCTIONS (Fx) during welding.

•

Some of the values edited will be used immediately by the operator, while others will be active from when the next welding

task begins.

• The HOLD function is not active within the SPECIAL FUNCTIONS Menu (SET UP Fx).

3 - PRE-SETTING MMA

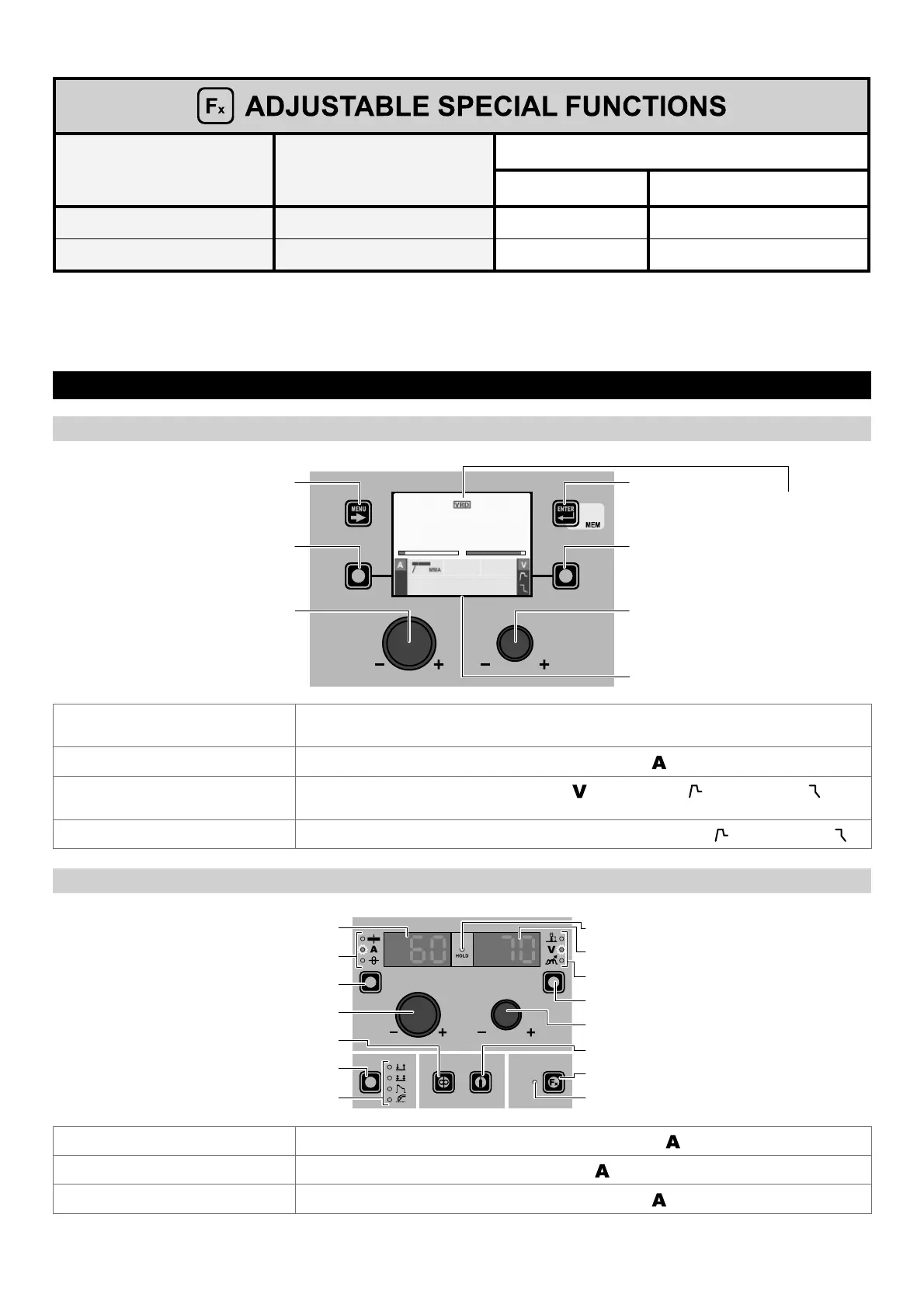

“DH” CONTROL PANEL

MENU KEY ENTER/MEM KEY

VRD ACTIVE

ENCODER KNOB - SX ENCODER KNOB - DX

VISION SCREEN

SX KEY DX KEY

AV

60 70.0

MMA Cr Ni

PROGRAM 3200

MENU KEY

Used to access the PROCESS SELECTION Menu (PROCESS) and subsequent menus, as

applicable.

ENCODER K

NOB - SX

Adjust the value of the parameter WELDING CURRENT (

).

DX K

EY

Scrolls in succession WELDING VOLTAGE ( ) - HOT START ( ) - ARC FORCE ( ) only

on the VISION S

CREEN (the operation is activated when the key is released).

ENCODER KNOB - DX

Adjusts the parameter selected using the DX K

EY (only HOT START ( ) - ARC FORCE ( )).

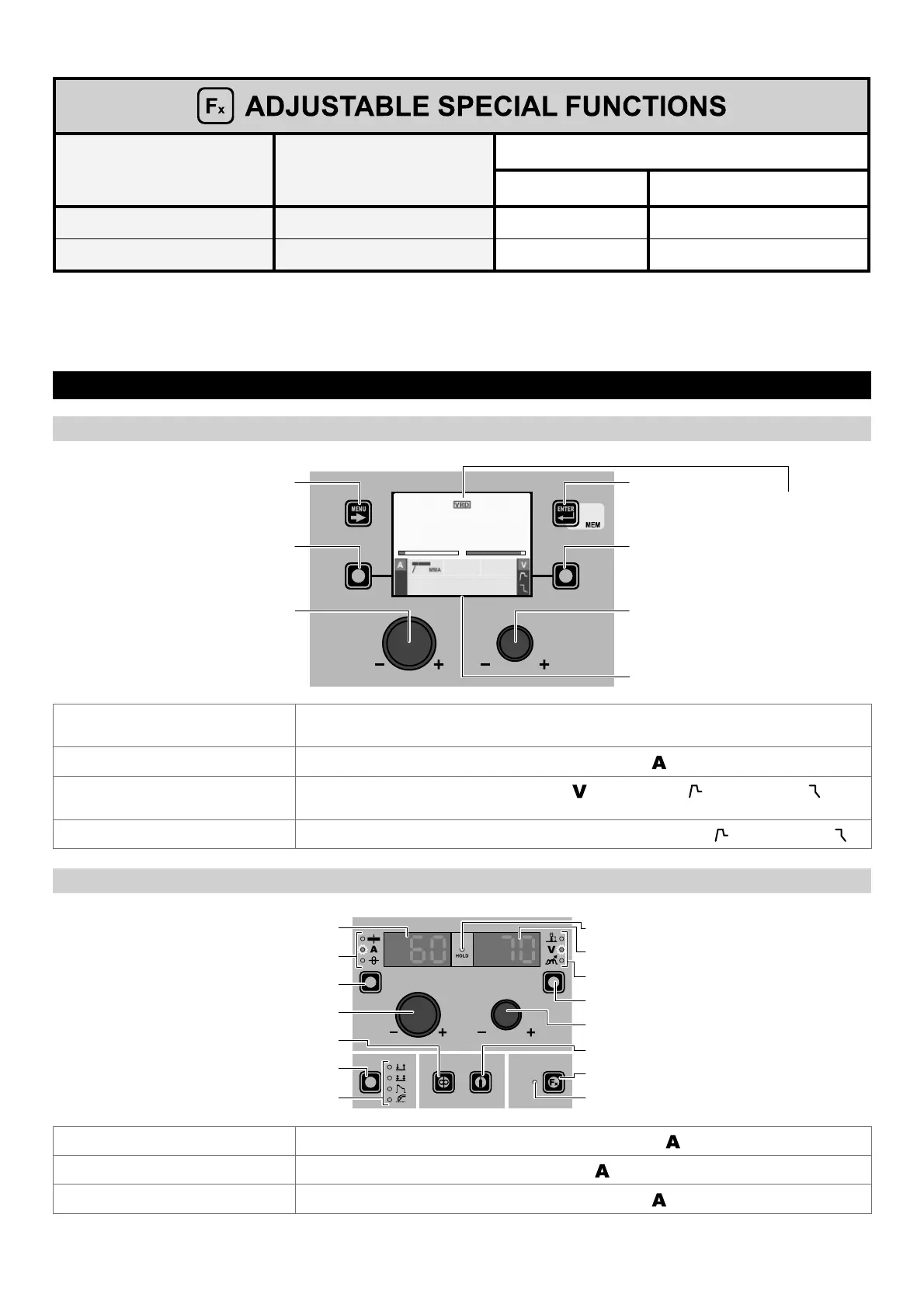

“HT4” CONTROL PANEL

WELDING MODE SELECTION LED

WELDING MODE SELECTION K

EY

WIRE KEY

ENCODER KNOB - A

PARAMETER SELECTION K

EY - A

PARAMETER SELECTION LED - A

PARAMETER DISPLAY S

CREEN - A

SPECIAL FUNCTIONS (FX) LED

SPECIAL FUNCTIONS (FX) KEY

GAS KEY

ENCODER KNOB - V

PARAMETER SELECTION KEY - V

PARAMETER SELECTION LED - V

PARAMETER DISPLAY SCREEN - V

HOLD Function LED

PARAMETER DISPLAY SCREEN - A

Displays the value of the parameter WELDING CURRENT (

).

PARAMETER SELECTION LED - A

The LED unit shows the WELDING CURRENT (

) switched on.

ENCODER K

NOB - A

Adjust the value of the parameter WELDING CURRENT (

).

(continued)

Loading...

Loading...