69

Advanced function Description

REMOTE CONTROL

ARC ON TIMER 0 gg. 0:00:00

TIMER WELDER ON 0 gg. 0:13:20

ENERGY SAVING ULTRA

REMOTE CONTROL ANALOGIC RC

By rotating the ENCODER KNOB - DX (this operation does not require confirmation) you

can choose to enable and/or disable an analogue output on the welding plant.

• DISABLED - Analogue output disabled, no type of remote control can be connected to

the plant.

Fe G3 SI-1 Ø 1.6 CO2

PROGRAM 0004

AV

95 11.4

ANALOGIC RC

• ANALOGIC RC (*) - Analogue output enabled for connection of an ANALOGIC RC

control.

WARNING:

(*) Function enabled by DEFAULT on the welding plant when it comes out of the factory.

The image (to the left) graphically shows how insertion of an ANALOGIC RC remote

control is shown on the VISION S

CREEN, when the welding machine is working normally.

Fe G3 SI-1 Ø 1.6 CO2

PROGRAM 0004

AV

95 11.4

PLC

• PLC - Analogue output enabled for insertion of a live cable if necessary.

WARNING:

The image (to the left) graphically shows how insertion of a a live control (PLC) is

shown on the VISION S

CREEN, when the welding machine is working normally.

To exit the ADVANCED CONFIG Menu and go back to the ADVANCED SETUP Menu:

• Push the MENU K

EY.

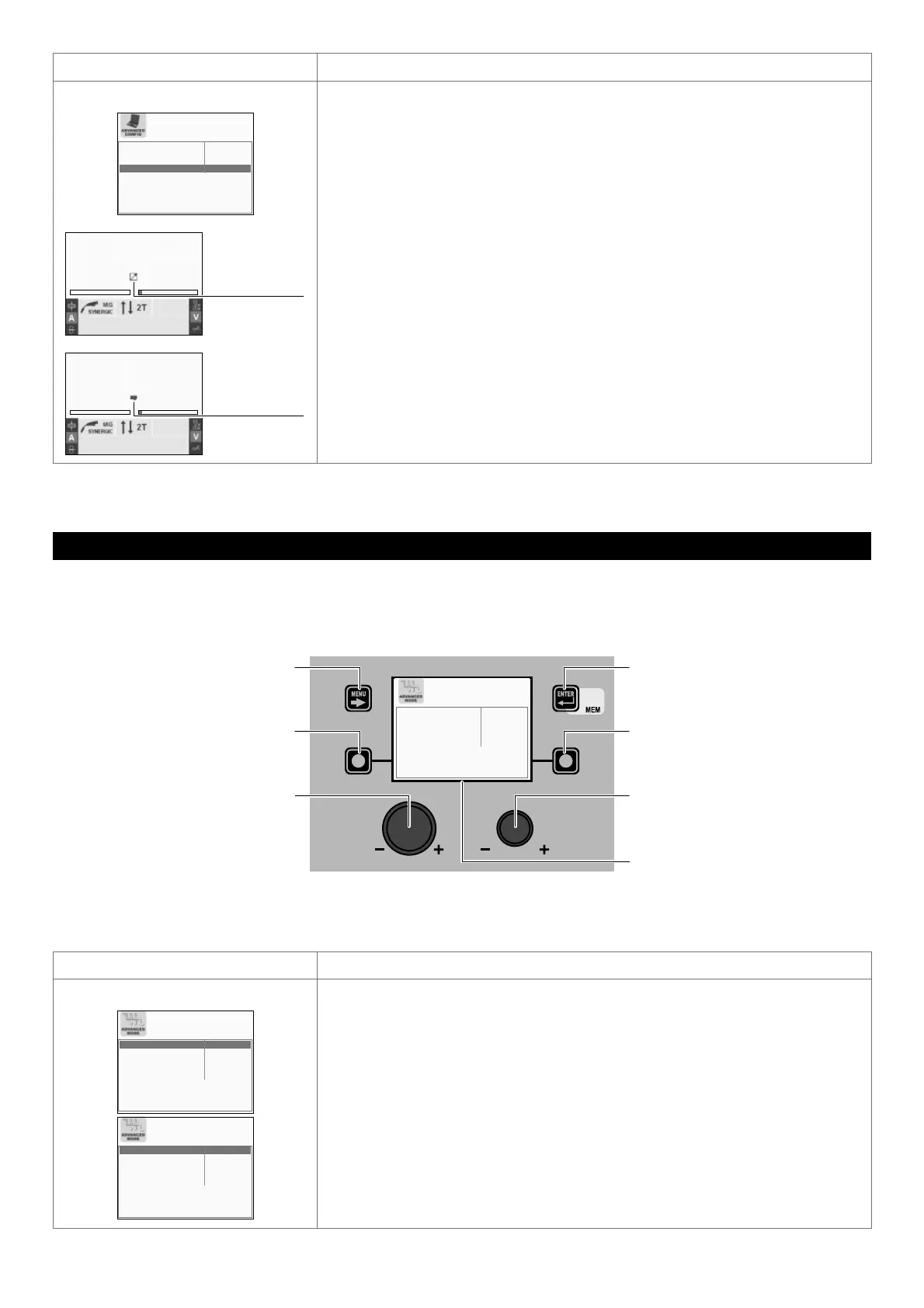

ADVANCED MODE ADVANCED SETUP Menu

The purpose of this menu is to allow the operator to further refine adjustments to the welding parameters for the machine.

To access the ADVANCED MODE Menu from the ADVANCED SETUP Menu:

• Turn the ENCODER K

NOB - SX to select the desired icon.

• Push the ENTER/MEM K

EY.

MENU KEY ENTER/MEM KEY

ENCODER KNOB - SX ENCODER KNOB - DX

VISION SCREEN

SX KEY DX KEY

CYCLE DISABLED

CRATER STANDARD

DUAL PULSE STANDARD

ARC LENGTH ADJUSTMENT VOLTAGE

TIG LIFT MODE DISABLED

Within the ADVANCED MODE Menu it is possible, by rotating the ENCODER KNOB - SX, to choose the advanced welding mode re-

quired from the 4 available (according to the welding process selected) and this can be ACTIVATED (this operation does not

require confirmation) by rotating the ENCODER K

NOB - DX.

Advanced function Description

CYCLE

CYCLE STANDARD

CRATER STANDARD

DUAL PULSE STANDARD

ARC LENGTH ADJUSTMENT VOLTAGE

TIG LIFT MODE DISABLED

CYCLE ADVANCED

CRATER STANDARD

DUAL PULSE STANDARD

ARC LENGTH ADJUSTMENT VOLTAGE

TIG LIFT MODE DISABLED

If enabled, when operating in STANDARD or ADVANCED mode, this function provides

the operator with a further welding mode (CYCLE) and the special functions associated

with it, when using MIG (pulsed, double pulsed, synergic, or manual) welding processes.

The WELDING MODE SELECTION Menu (MODE) menu will therefore be changed.

This function can only be activated, with the above procedure, on the VISION Display,

whilst it can also be set on the HT4 drag-and-drop once it is activated.

See the special “WELD MODE SELECTION Key” paragraph for correct functioning of the

CYCLE welding mode.

(continued)

Loading...

Loading...