35

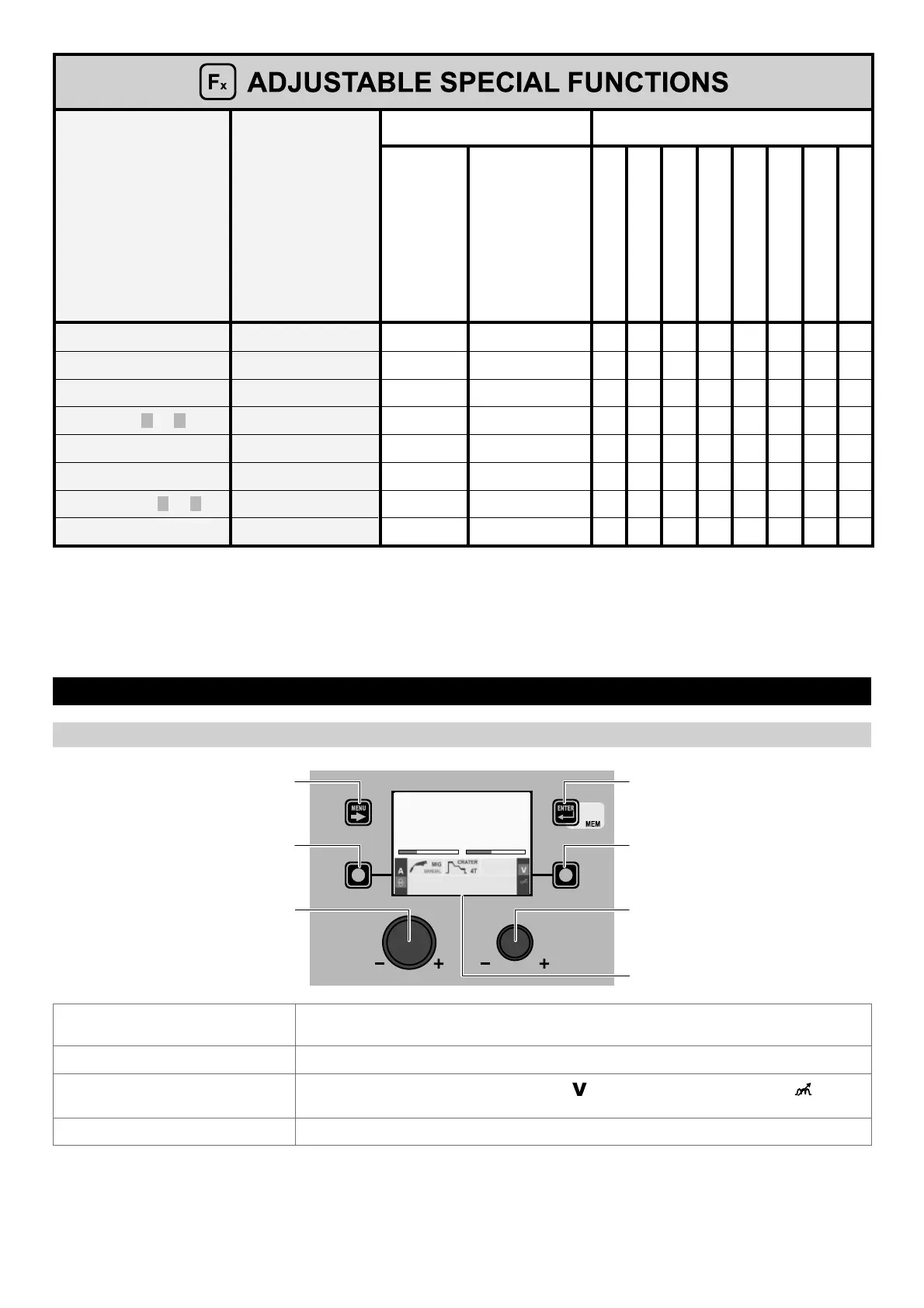

Special function

PARAMETER DISPLAY

Screen - A

PARAMETER DISPLAY Screen - V Welding mode

Default

Range

TWO STROKE (2T)

FOUR STROKE (4T)

CRATER 2T

CRATER 4T

SPOT WELDING

STITCH WELDING

CYCLE STANDARD

CYCLE ADVANCED

FINAL CRATER TIME F15 0.0s (0.0 - 5.0)s ●

BURN BACK bub 0 -30 - +30 ●●●●●●●●

POST GAS PoG 1.0s (0.0 - 10.0)s ●●●●●●●●

FIRST SLOPE ( I1 TO I 2 ) F18 0.05s (0.0 - 1.0)s ●

CYCLE WIRE SPEED F19 5.0m/min (0.6 - MAX)m/min ●●

CYCLE VOLTAGE F20 25.0V (min - MAX)V ●●

SECOND SLOPE ( I 2 TO I 1 ) F21 0.05s (0.0 - 1.0)s ●

ACS / ENCODER SPEED F28 100A/s (5 - 500)A/s ●●●●●●●●

WARNING:

• The STANDARD or ADVANCED welding CYCLE mode can only be activated by opening the ADVANCED SETUP Menu - AD-

VANCED MODE - CYCLE (for further explanations, see the relevant paragraph).

• It is possible to access editing of the SPECIAL FUNCTIONS (Fx) during welding.

•

Some of the values edited will be used immediately by the operator, while others will be active from when the next welding

task begins.

• The HOLD function is not active within the SPECIAL FUNCTIONS Menu (SET UP Fx).

3 - PRE-SETTING MIG-MAG manual

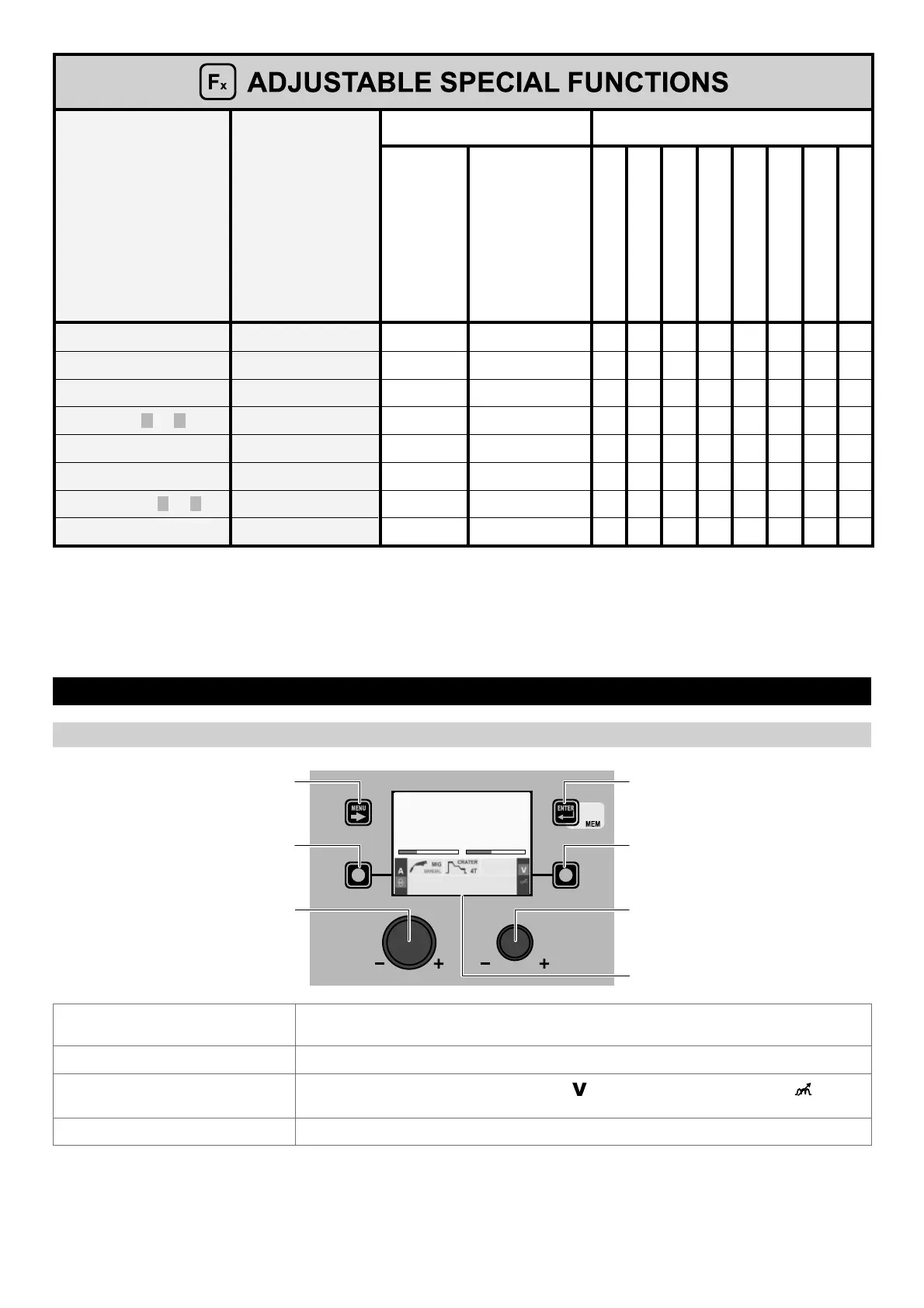

“DH” CONTROL PANEL

MENU KEY ENTER/MEM KEY

ENCODER KNOB - SX ENCODER KNOB - DX

VISION S

CREEN

SX KEY DX KEY

m/min V

7.8 31.3

MENU KEY

Used to access the PROCESS SELECTION Menu (PROCESS) and subsequent menus, as

applicable.

ENCODER K

NOB - SX Adjusts the parameter selected using the SX KEY.

DX K

EY

Scrolls in succession WELDING VOLTAGE ( ) - ELECTRONIC INDUCTANCE ( ) only on

VISION S

CREEN (this operation is activated when the key is released).

ENCODER K

NOB - DX Adjusts the parameter selected using the DX KEY.

Loading...

Loading...