70

Advanced function Description

CRATER

CYCLE ADVANCED

CRATER ADVANCED

DUAL PULSE STANDARD

ARC LENGTH ADJUSTMENT VOLTAGE

TIG LIFT MODE DISABLED

If enabled, when working in ADVANCED mode, this function provides the operator

with further welding modes related to the CRATER as well as the 2 special functions

explained below that make it possible to vary the length of the arc in the welding crater,

when using MIG (pulsed, double pulsed, synergic, and manual) welding processes.

• INITIAL ARC LENGTH (F09)

• FINAL ARC LENGTH (F14)

DOUBLE PULSED

CYCLE ADVANCED

CRATER STANDARD

DUAL PULSE ADVANCED

ARC LENGTH ADJUSTMENT VOLTAGE

TIG LIFT MODE DISABLED

If enabled, when working in ADVANCED mode, this function provides the operator with

the following special functions, when using the double pulsed MIG welding process:

• DOUBLE PULSED ARC LENGTH (F24)

Allows the welder to adjust the length of the arc on both double pulsed levels.

• FIRST SLOPE (from I

1 to I 2 ) (F22)

• SECOND SLOPE (from I

2 to I 1 ) (F27)

These two special functions allow the welder to adjust the ramp for passing between

the two double pulsed levels.

ARC LENGTH ADJUSTMENT

CYCLE DISABLED

CRATER STANDARD

DUAL PULSE STANDARD

ARC LENGTH ADJUSTMENT VOLTAGE

TIG LIFT MODE DISABLED

This function allows an operator using the (pulsed, double pulsed, synergic and manual)

MIG welding process to adjust the ARC LENGTH ADJUSTMENT (

) parameter with the

WELDING VOLTAGE (

) or the WIRE SPEED ( ).

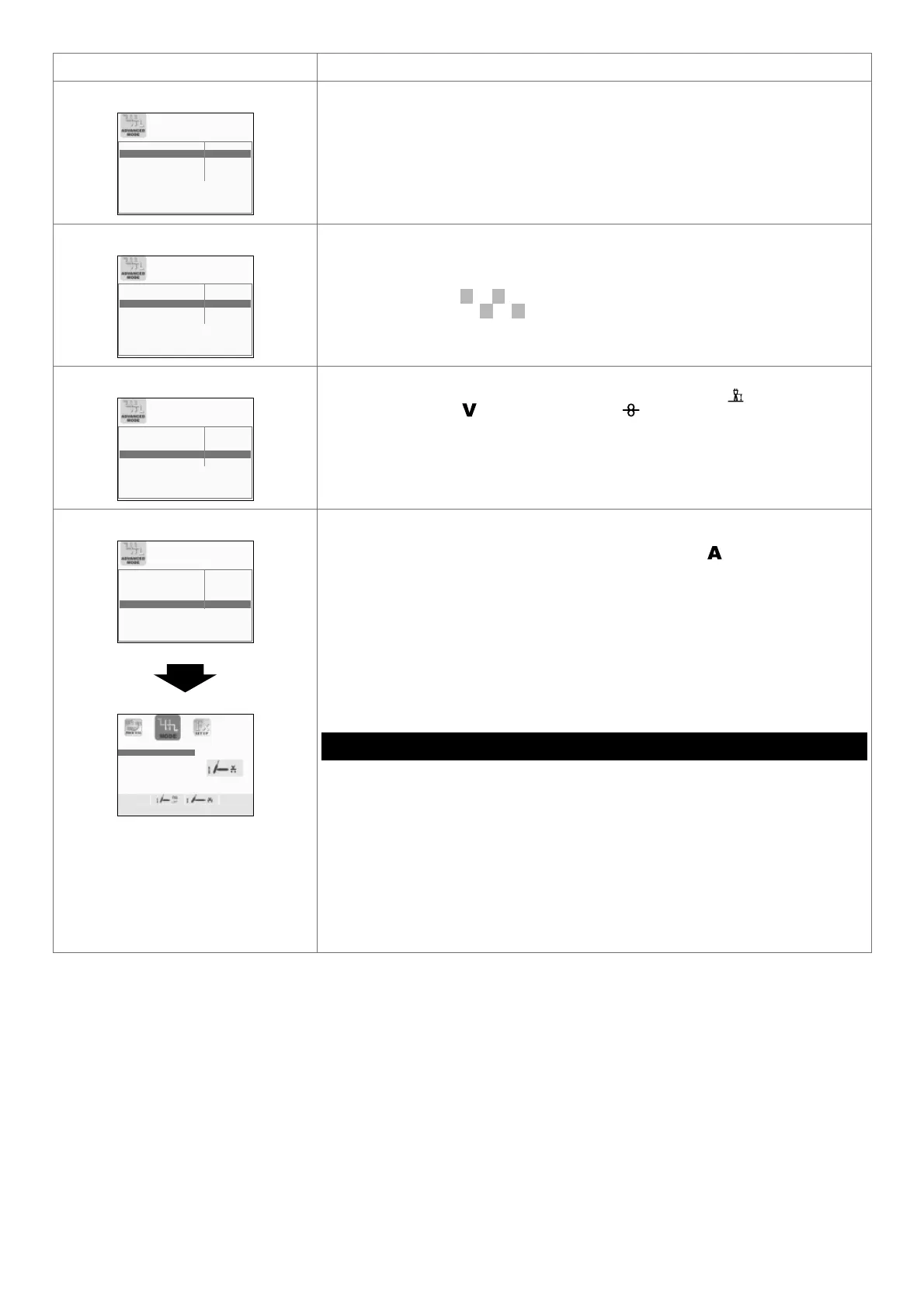

TIG LIFT MODE

CYCLE DISABLED

CRATER STANDARD

DUAL PULSE STANDARD

ARC LENGTH ADJUSTMENT VOLTAGE

TIG LIFT MODE ENABLED

TIG LIFT

TIG LIFT TORCH TRIGGER

If activated, this function makes an additional welding mode known as TIG LIFT TORCH

TRIGGER available to an operator using the TIG LIFT welding process.

In this mode the welder can control the WELDING CURRENT (

) parameter, using the

button on the TIG torch.

WARNING: To allow TIG LIFT WITH TORCH TRIGGER welding, the DIGITECH

PULSE needs a specific female connector to be fitted on it (NON-STANDARD

MACHINE) to which the corresponding male connector on the TIG torch is to be

connected.

Therefore, for the TIG LIFT welding process, a new menu will be created (see figure)

named WELDING MODE SELECTION Menu (MODE).

WELDING MODE SELECTION Menu (MODE)

To access the WELDING MODE SELECTION Menu (MODE) push the MENU KEY.

“DH” CONTROL PANEL

MENU K

EY - Used to access subsequent menus, where applicable.

ENCODER K

NOB - SX - Selects the welding mode.

ENTER/MEM K

EY - Used to access the PRE-SETTING for the program selected

beforehand, with the welding MODE chosen.

“HT4” CONTROL PANEL

It is not possible to access the WELDING MODE SELECTION Menu (MODE) via the

“HT4” control panel.

To exit the ADVANCED MODE Menu and go back to the ADVANCED SETUP Menu:

• Push the MENU K

EY.

Loading...

Loading...