Page 32 FF6300 Operating Manual

3.6 INSTALLING THE ID CHUCK IN THE WORKPIECE

See Section Section 3.5 on page 30 for a full list of installation hazard warnings.

The machine ships with the main body mounted to the ID chuck. See Section 3.7 on

page 36 for OD mounting or Section 3.8 on page 42 for surface mounting.

The FF6300 ID chuck can be removed from the main body rotating assembly. The

chuck can be installed independently as a subassembly when there are access or

rigging constraints. It can also remain attached to the main body during the machine

installation.

Use supplemental rigging when mounting the machine, in case it falls out

or through the chucking diameter.

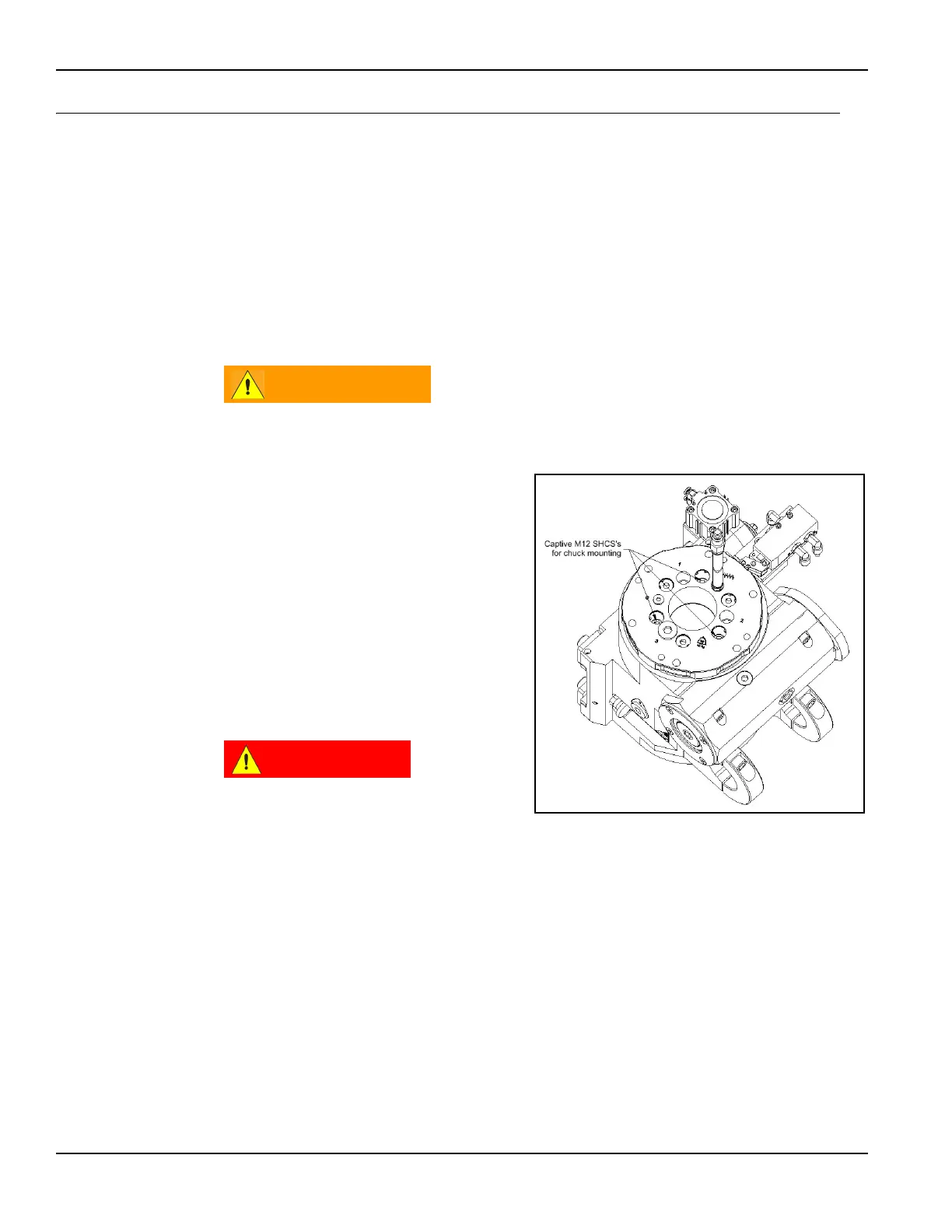

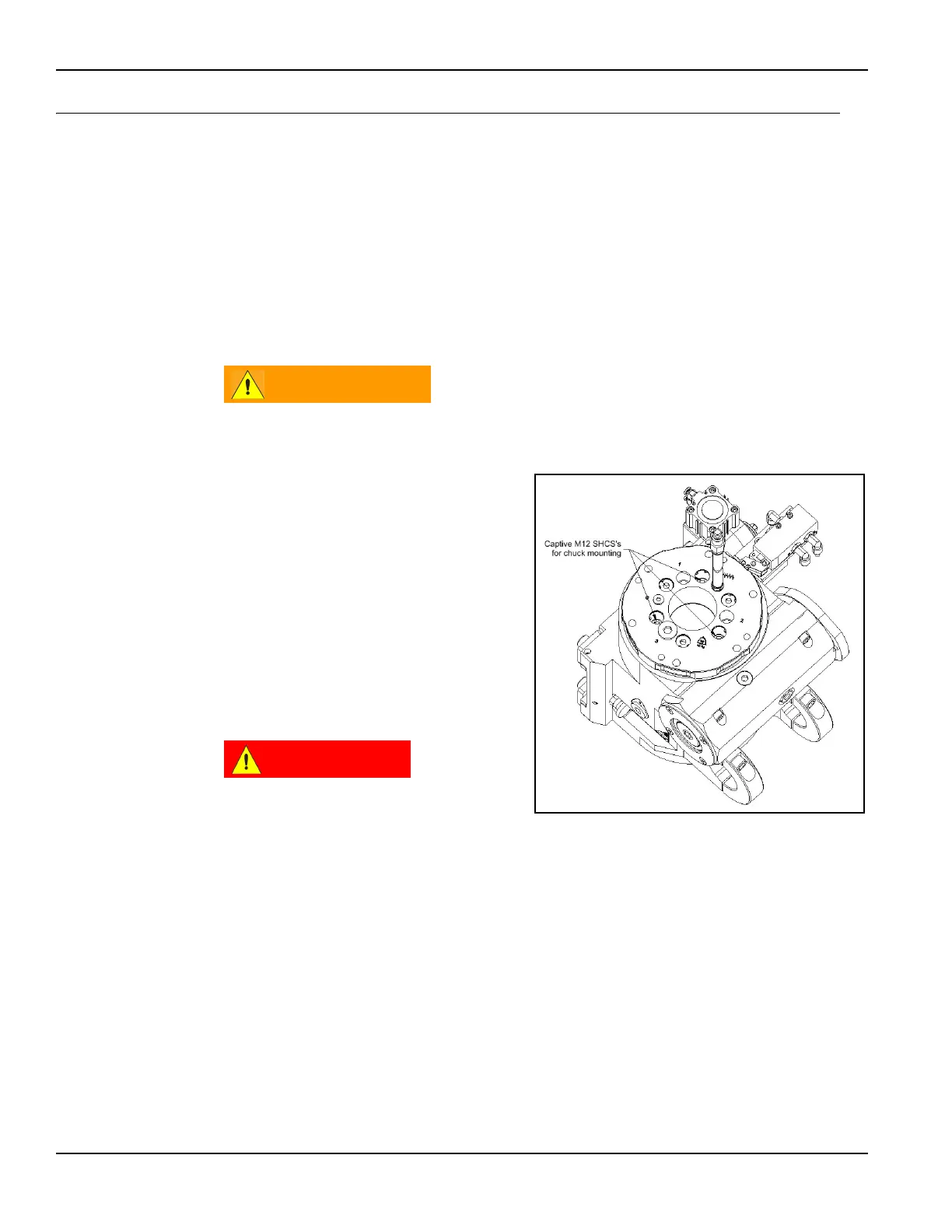

The ID chuck hub is attached to the

main body by three M12 through-bolts

that pass through the main machine

spindle (Figure 3-10).

Because the ID chuck secures the

machine to the workpiece, it is very

important that the chuck be securely

clamped into position. Common appli-

cations include both flange faces that

are horizontal (on the same plane as

the floor or overhead) or vertical.

Whenever there is a possibility

of the machine falling out of or

through the chucking diameter,

take special care to check that

the ID chuck is secure before releasing the rigging.

FIGURE 3-10. ATTACHING THE ID CHUCK TO THE MAIN BODY

Loading...

Loading...