Page 64 FF6300 Operating Manual

5.2 MAINTENANCE INTERVALS

Table 5-1 lists maintenance intervals and tasks, along with the section where each task

is described.

5.3 MAINTENANCE TASKS

5.3.1 Check the pneumatic conditioning unit oil reservoir levels

1. Check the pneumatic conditioning unit (PCU) oil reservoir levels.

2. Refill as necessary. See Table 5-2 on page 68 for information on recommended

lubricants.

3. Check that the oil drip rate is set at six drops per minute (Figure 2-7 on

page 21).

5.3.2 Empty the air filter water trap

Check and drain the water from the air filter water trap.

5.3.3 Pneumatic conditioning unit emergency stop check

1. With the machine running, press the emergency stop button (Figure 2-7 on

page 21).

2. Check that the machine stops.

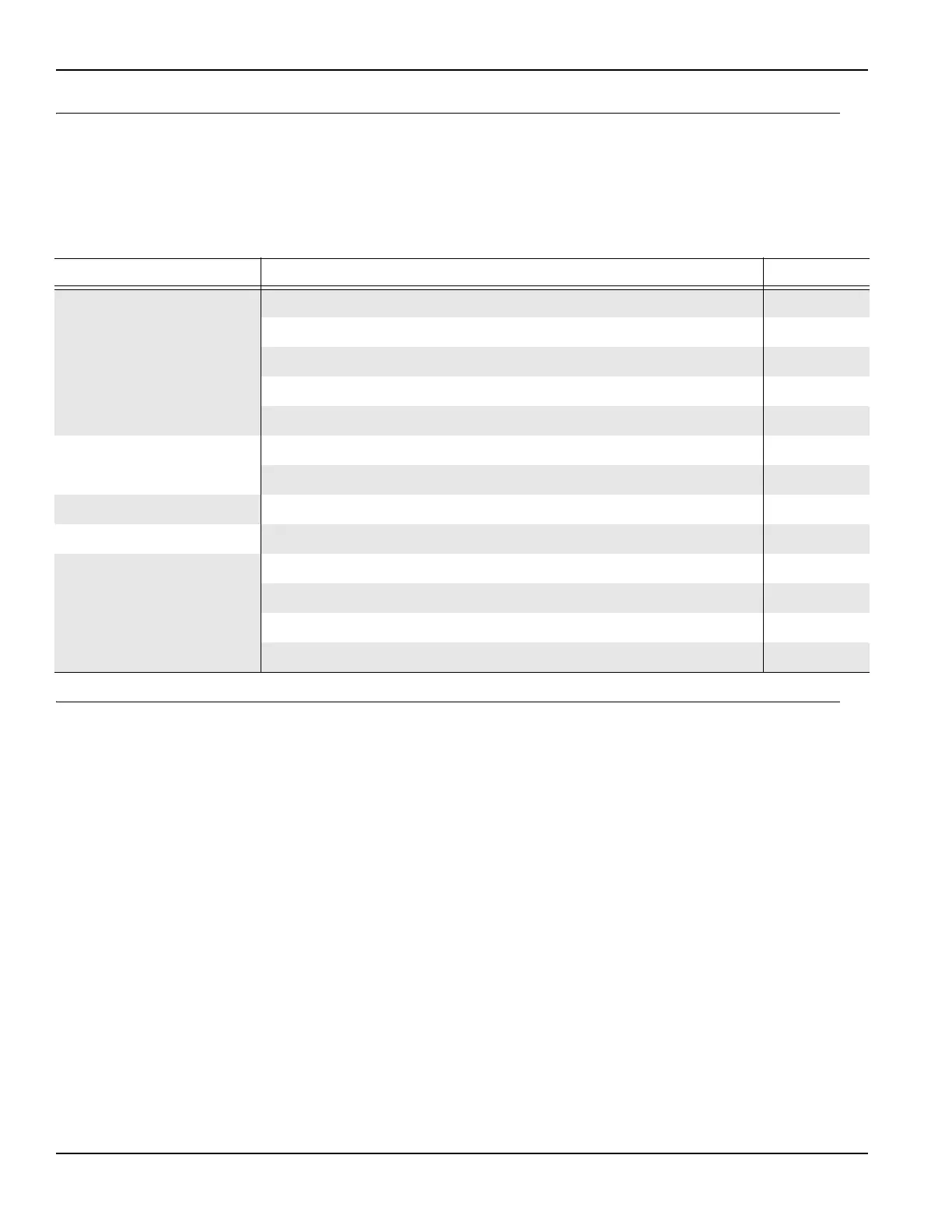

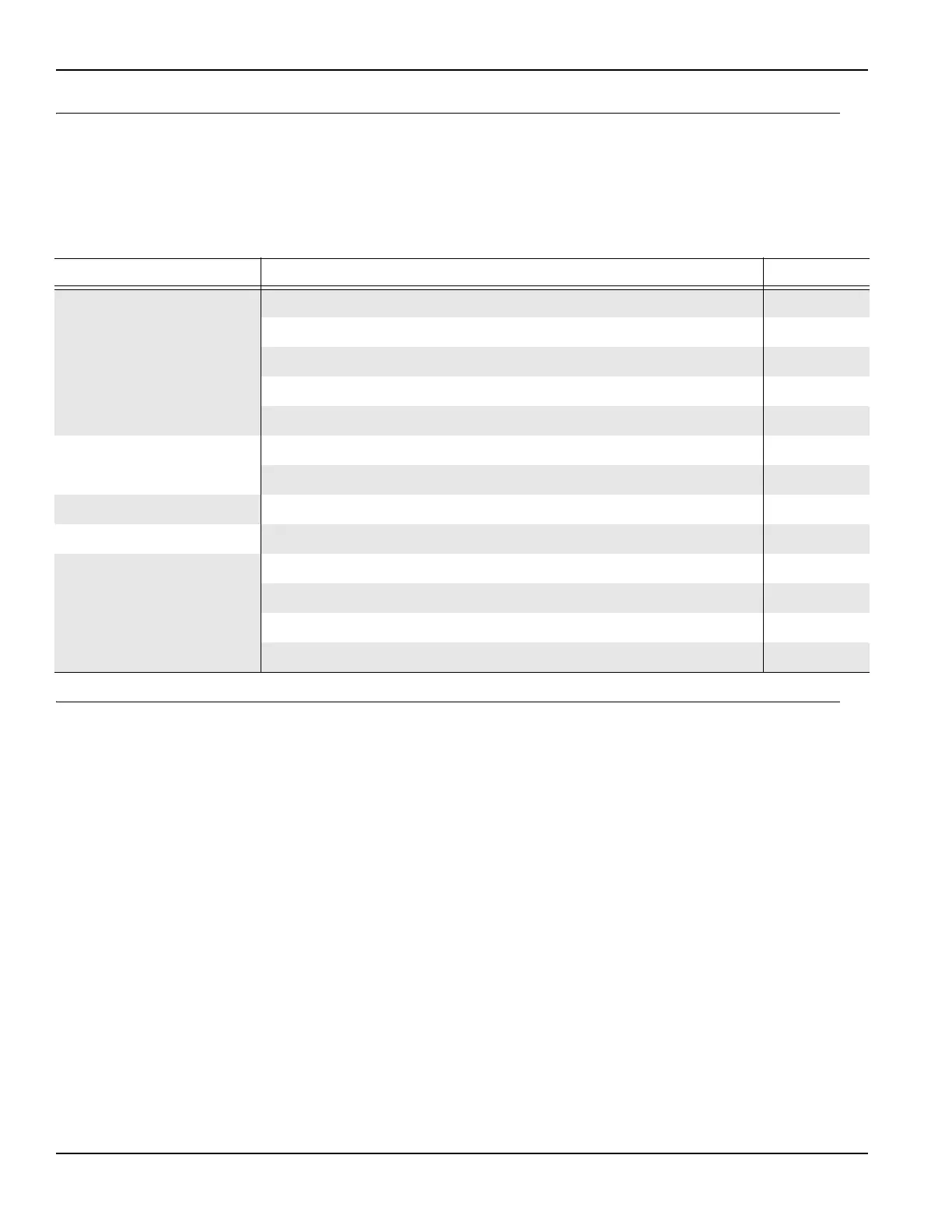

TABLE 5-1. MAINTENANCE INTERVALS AND TASKS

Interval Task See section

Before each use

Check the pneumatic conditioning unit oil reservoir levels. 5.3.1

Check the pneumatic lines for damage and wear. --

Perform a pneumatic conditioning unit emergency stop check. 5.3.3

Perform a pneumatic conditioning unit drop-out circuit check. 5.3.4

Perform hydraulic power unit maintenance. 5.3.5

Before and after each

use

Remove debris, oil, and moisture from machine surfaces. --

Perform leadscrew maintenance. 5.3.7

After each use Perform dovetail and square ways maintenance. 5.3.6

Periodically

Empty the air filter water trap. 5.3.2

As needed

Perform leadscrew maintenance. 5.3.7

Adjust the dovetail and square ways gib screws. 5.3.8

Adjust the radial slide lead nut. 5.3.9

Tram the turning arm. 5.3.10

Loading...

Loading...