P/N 80679, Rev. 10 Page 45

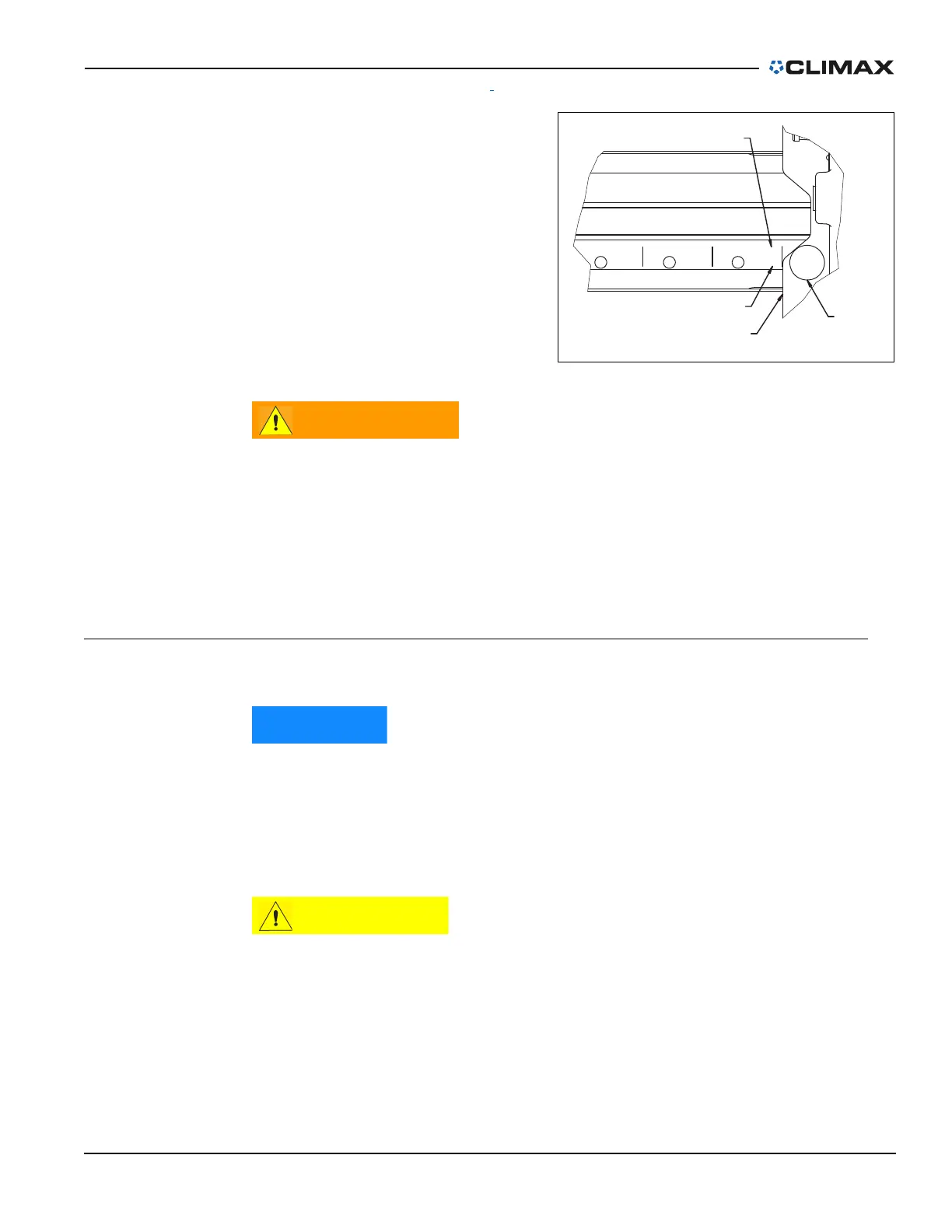

2. Slide the arm to the desired

position.

The machining arm is engraved

with and centimeter markings

on the face of the slide to help

you set the position. Because

the arm is moved radially from

center, the scale shows es and

centimeters in half increments,

measured from the edge of the

main housing (Figure 3-27).

3. Release the safety stop pin.

Position the machining arm so that the safety stop pin engages the

retention notch in the machining arm.

Do not disable the safety stop pin. The safety stop pin is intended to

prevent unwanted shifting of the machining arm, which could result in

serious injury or death.

4. Tighten the clamps to approximately 50 ft-lbs (68 Nm).

3.10 POSITIONING THE COUNTERWEIGHT

The counterweight must be installed when the machine is used in a vertical

machining application. CLIMAX recommends that you always use the

counterweight as it improves the performance of the machine and

produces a flatter surface.

The counterweight arm can be adjusted to balance the machine.

For precise machining and to avoid damage to the machine, the

counterweight and machining arm should always be equally spaced from

the center of the machine.

After positioning the turning arm, do the following to adjust the counterweight to

balance the machine:

1. Suspend the machine from the two lifting points on top of the main body.

FIGURE 3-27. DETAIL OF MACHINING ARM

SPRING

LOADED PIN

MEASUREMENTS

RELATIVE TO THIS EDGE

MACHINING

DIAMETER IN CM

MACHINING DIAMETER

IN INCHES

152

60

142

56

132

52

Loading...

Loading...