Page 70 FF6300 Operating Manual

• To manually rotate the pneumatic machine, insert a 10-mm hex wrench in

the hex opposite the motor or push on the end of the turning arm.

• To manually rotate the hydraulic machine, use the cross-connection hose

supplied with the machine to connect the #1 and #2 port hoses. Insert a 10-

mm hex wrench in the hex opposite the motor or push on the end of the

turning arm.

5.5.2 The machine isn’t feeding

If the machine isn’t feeding properly, check the following:

1. There is air pressure entering and leaving the PCU. Check the air pressure by

disconnecting the hose quick disconnects and checking for air bleed (Figure 2-

7 on page 21).

2. The emergency stop is reset (Section 5.3.3 on page 64 for PCU and

Section 2.3.2 on page 21 for HPU).

3. The feed is engaged (Figure 3-33 on page 48).

4. The air valve assembly is assembled correctly (Figure A-8 on page 88,

Figure A-19 on page 99, and Figure B-1 on page 111). Check that the 3/8" (9.5

mm) and 1/4" (6.4 mm) quick disconnects are connected to the correct hose

connections on the spindle cap.

5. The leadscrew is free to turn in the desired direction. On the end of the turning

arm, insert a 10-mm hex wrench to use as a crank handle and then turn it.

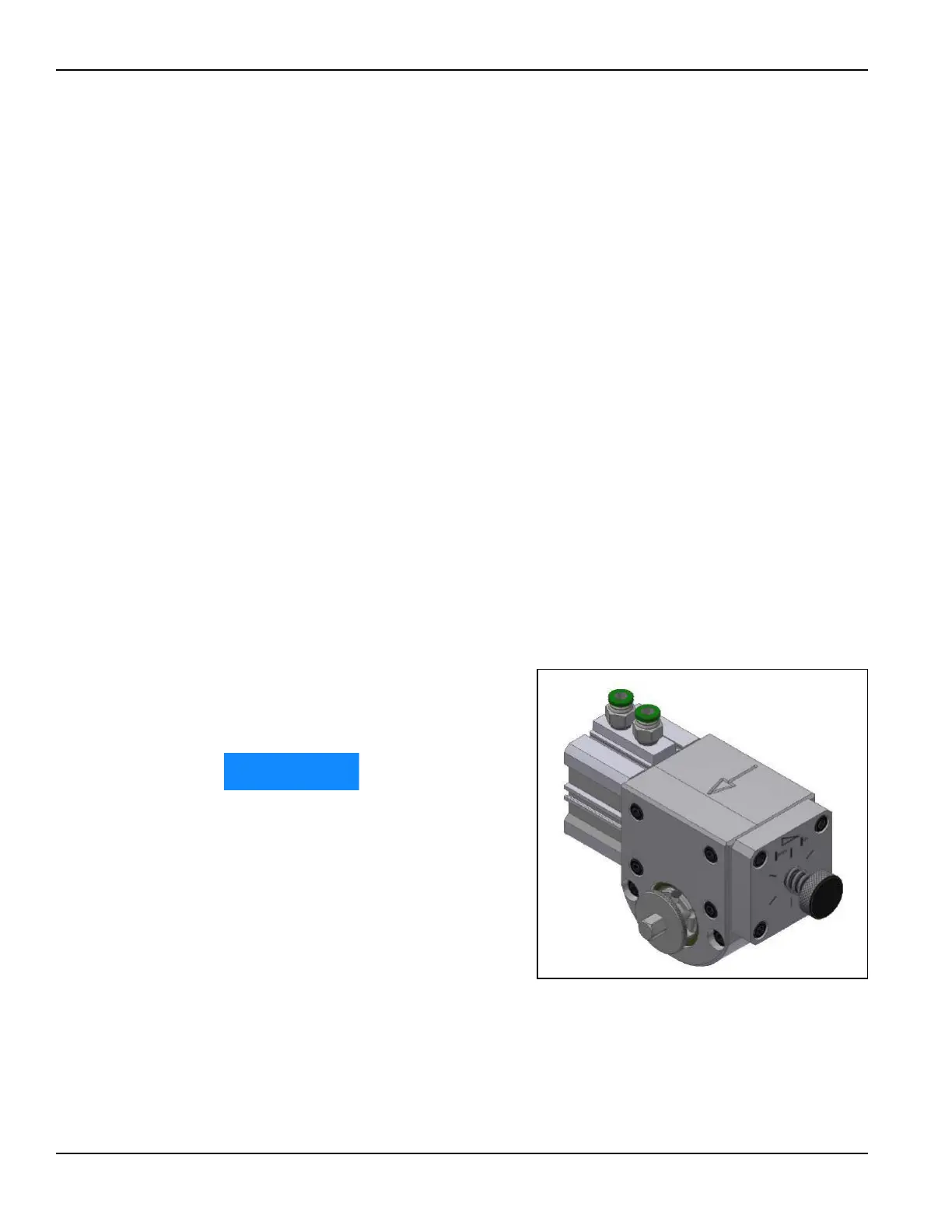

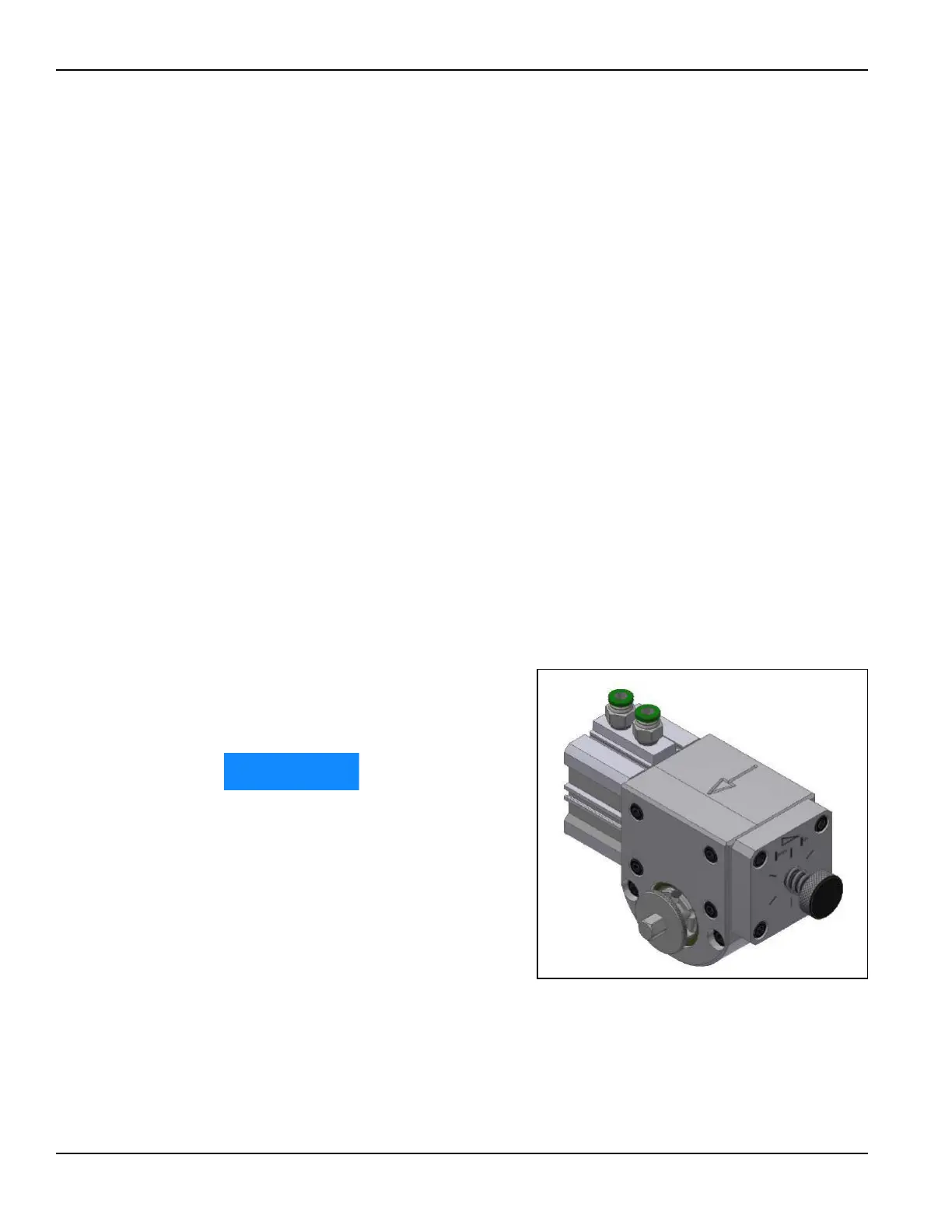

5.5.3 The feed is slow or unresponsive

If the feed is slow or unresponsive, the

most likely cause is dirty air filters on

the feed box.

Clean both filters at the same

time.

Do the following to clean the feed box

air filters:

1. Unscrew and remove the air fil-

ters on either end of the feed

box (Figure 5-3).

2. Clean the filters with solvent.

3. Blow out the filters with com-

pressed air.

4. Replace the filters in the feed box.

FIGURE 5-3. LOCATION OF FEED BOX FILTERS

Loading...

Loading...