AIR HANDLING SUB-SYSTEM

Filter

(-)GRA/(-)GTA units come with a low

pressure drop permanent filter made

of thermoplastic material. It has been

ASHRAE evaluated for dust spot and

dust holding capacity. The filter must

be cleaned at regular intervals for

proper furnace operation.

Blower Motor

All units come with three, or four,

speed direct drive blowers capable of

moving air for heating and cooling.

The PSC motor operates on the

appropriate speed when the owner

switches the thermostat to heating

or cooling. The 45,000 BTUH and

60,000 BTUH units come with

1/2 horsepower motors. The 90,000

BTUH, 105,000 BTUH, and 120,000

BTUH units use a 3/4 horsepower

motor. 75,000 BTUH units can be

ordered with either a 1/2 or 3/4

horsepower motor. All motors are

permanently lubricated.

Blower Motor Capacitor

Each motor uses a 1-3/4 inch run

capacitor mounted to the side of the

blower housing. The 1/2 HP motors

use a 370 volt, 7 -1 /2 mfd capacitor

and the 3/4 HP motors use a 370

volt, 15 mfd capacitor.

Blower Wheel

All furnaces use forward curved

blower wheels that directly mount to

the motor shaft. There are four

wheel sizes: the 45,000 BTUH,

60,000 BTUH, and 75,000 BTUH

standard cabinet models use a

11" x 7" (diameter x width) wheel.

The 120,000 BTUH unit uses a

11" x 10" wheel. The 90,000 BTUH

and 105,000 BTUH units use a

12" x 11" wheel. 75,000 BTUH wide

cabinet models use the 12" x 7"

blower wheel. See the physical data

and specifications tables for details.

CABINET

Cabinet Body

(·)GRA/(-)GTA units come in a

cabinet of prepainted galvanized

steel. There are access openings on

both sides (upflow units) or in the top

(downflow units) for electrical power.

Gas piping, and condensate drain

openings are on both sides. Com-

bustion air piping enters on the top

and right side of upflow units, or top

only on downflow units. The exhaust

piping opening is in the top plate.

Return air can enter through the

sides, bottom or back of upflow units.

(-)GRA units come with a factory

installed base pan which must be

removed when using bottom air

return. This cabinet body is of an

identical design as previous Low

Profile furnaces to mate with all

standard accessories.

The burner compartment is air tight

and acts as a combustion air entry

chamber. All unused openings come

with seals. The gas pipe and

combustion air openings have

gaskets to assure an airtight seal.

Doors

Both the burner compartment door

and the blower compartment door

attach and lock in place with

thumbscrews for quick removal and

replacement. They are made of

galvanized pre-painted steel. The

burner compartment door has gasket

material on its inside edge for an

airtight seal and has a sightglass to

view burner operations.

ACCESSORIESAND

OPTIONALEQUIPMENT

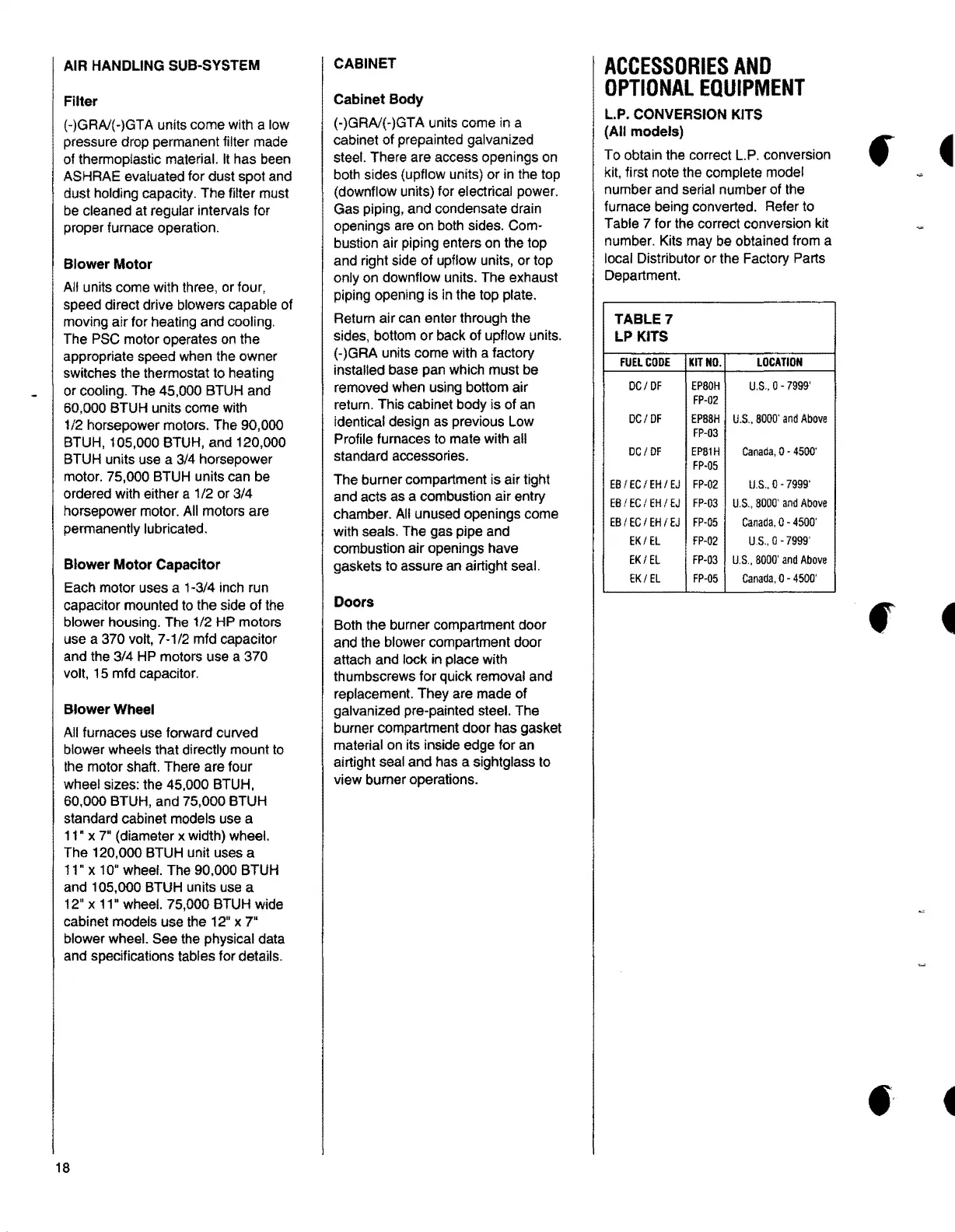

L.P. CONVERSION KITS

(All models)

To obtain the correct L.P. conversion

kit, first note the complete model

number and serial number of the

furnace being converted. Refer to

Table 7 for the correct conversion kit

number. Kits may be obtained from a

local Distributor or the Factory Parts

Department.

TABLE7

LP KITS

FUELCODE KITNO. LOCATION

DC/ OF EPSOH

u.s,0 7999'

DC/ OF

FP-02

EP88H

U.S.,

sooo·and Above

DC /OF

FP-03

EP81H Canada,O • 4500'

FP-05

EB / EC

I EH / EJ

EBiEC/EH/EJ

FP-02

FP-03

U.S., 0 7999"

U.S., 8000' and Above

EBIEC/EH/EJ

FP-05 Canada,O • 4500'

EK/ EL

EK/ EL

FP-02

FP-03

U

s.,0 • 7999'

U.S , 8000' and Above

EK/ EL FP-05 Canada,O 4500'

t

18

Loading...

Loading...