I

AIR FLOW

The importance of proper air flow

over the heat exchanger cannot be

over emphasized. One of the most

common causes of heat exchanger

failure is overheating due to low air

flow An air flow table is located

inside the blower door.

Temperature Rise Check. To

determine if the air flow is correct,

make a temperature rise check.

1. Insert a thermometer in the

supply air duct as close to the

furnace as possible yet out of a

direct line from the heat

exchanger.

2. Insert a thermometer in the

return air duct as close to the

furnace as possible.

3. Operate the furnace.

4. When the thermometer in the

supply air duct stops rising

(approximately 5 minutes),

subtract the return air

temperature from the supply air

temperature. The difference is

the temperature rise.

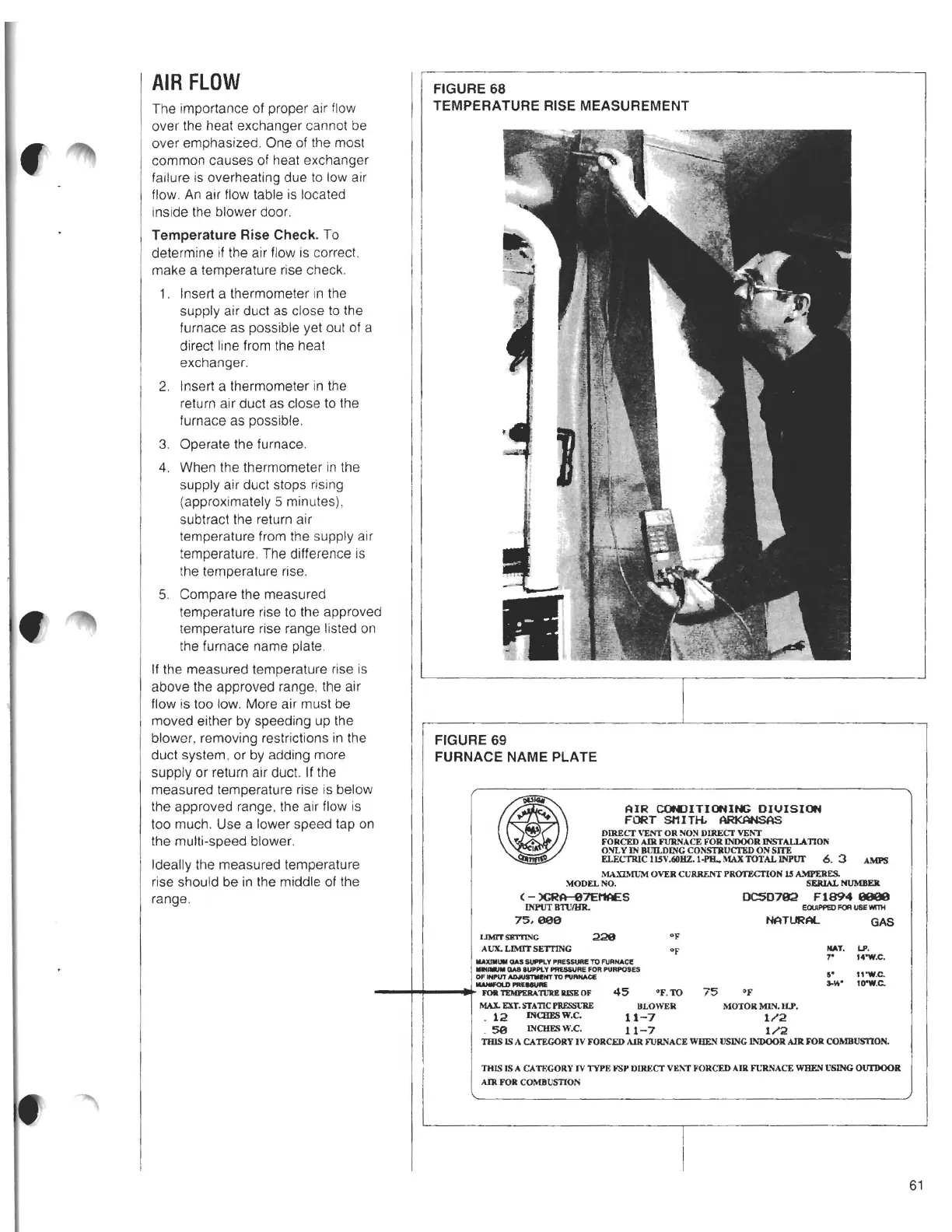

5. Compare the measured

temperature rise to the approved

temperature rise range listed on

the furnace name plate.

If the measured temperature rise is

above the approved range, the air

flow is too low. More air must be

moved either by speeding up the

blower, removing restrictions in the

duct system, or by adding more

supply or return air duct. If the

measured temperature rise is below

the approved range, the air flow is

too much. Use a lower speed tap on

the multi-speed blower.

Ideally the measured temperature

rise should be in the middle of the

range.

---+-+--~~

FIGURE 68

TEMPERATURE RISE MEASUREMENT

FIGURE 69

FURNACE NAME PLATE

AIR COt«llTIONINC OIUISION

FORT SMITH,

~

DIRECT \'ENT OR NON DIRECT VE!loT

FORCED AIR FURNACE FOR INDOOR INSTALLATION

OSI.YIN BUll.DING CONSTRUCI"ED ON SITE

ELECl1llC 115V.60HZ.1-PIL, MAX TOTAL INPUr 6. 3 AMPS

MAXIMUM OVER CURRENT PROTECTION 1.5AMPERES.

MODEL NO.

( - >GRA-07El1AES

INPUT BTIJ/HR.

75, 000

l.lMITSin"llNG

220

AUX. LIMIT SETTING

IIAXJMUM OAS SUP9'LY PRESSURE TO FUANACe

IIIINIMUM OA8 IUPPL Y PRESSURE FOR PURPOSES

OF INPUT ADIUSTlll!NT TO flURNACE

~PRH8UIIE

ro11TEMPERATIJJtEIUSl!OF 45

SERIAL NUMBER

OC50702 F1894 0080

ECUIPPal FOR USEwm<

NATURAL GAS

NAT. LP.

7•

14-W.C.

11·w.c.

10-W.C.

•r.ro 75 •r

MAX.EXT.STATIC PRESSl.l!E BLOWER MOTOR MIN. H.P .

. 12 INCHESW.C. 11-7 1/2

. 58

INCHESW.C. 11-7 1/2

nus IS A CATEGORY IV FORCED AIR FURNACE WHE.'1 USING INDOOR AIR FOR COl\mUSTION.

THIS IS A CA TF,GORY IV TYPE ~'SP DIRECT VE1'T FORCED Alli FCIINACE WHEN l!SING OUTDOOR

AIR FOR COMBUSTION

61

Loading...

Loading...