company for the location of the

manual main shut-off valve. The gas

line and manual gas valve must be

adequate in size to prevent undue

pressure drop and never smaller

than the pipe size to the combination

gas valve on the furnace. Refer to

Table 19 for the recommended gas

pipe size.

See Figure 59 for typical gas pipe

connections. A ground joint union

must be installed within three feet of

the furnace so the control assembly

may be easily removed. Install a

manual shut-off valve upstream of

this ground joint union. The valve

should be readily accessible for

turning the gas supply on or off. A

drip leg should be installed in the gas

supply line as close to the furnace as

possible.

A pipe compound resistant

to the action of liquefied petroleum

gases must be used on all threaded

connections.

IMPORTANT: WHEN MAKING GAS

PIPE CONNECTIONS, USE A

BACK-UP WRENCH TO PREVENT

ANY TWISTING OF THE CONTROL

ASSEMBLY AND GAS VALVE. ANY

STRAINS ON THE GAS VALVE

CAN CHANGE THE POSITION OF

THE GAS ORIFICES IN THE

BURNERS. THIS CAN CAUSE

ERRATIC FURNACE OPERATION.

IMPORTANT: ENSURE THAT THE

FURNACE GAS CONTROL VALVE

NOT BE SUBJECTED TO HIGH

GAS LINE SUPPLY PRESSURES.

DISCONNECT THE FURNACE AND

ITS INDIVIDUAL SHUT-OFF VALVE

FROM THE GAS SUPPLY PIPING

DURING ANY PRESSURE

TESTING THAT EXCEEDS 1/2

P.S.I.G. (3.48

KPA). The furnace

must be isolated from the gas supply

piping by closing its individual

manual shut-off valve during any

pressure testing of the gas supply

piping system at test pressures equal

or less than 1/2 p.s.i.g. (3.48 kPa).

IMPORTANT: DO NOT RUN A

FLEXIBLE GAS CONNECTOR

INSIDE THE UNIT. EXTEND THE

1/2" BLACK PIPE FROM THE GAS

VALVE TO THE OUTSIDE OF THE

CABINtT. IF ALLOWED BY CODE,

CONNECT ANY FLEXIBLE GAS

CONNECTOR FROM THERETO

THE GAS PIPING. The gas pipe

gasket in the cabinet does not seal

around a flexible gas connector. It is

important to have all openings in the

cabinet burner compartment sealed

for proper furnace operation.

GAS PRESSURE

Natural gas supply pressure should

be 5" to 10.5" w.c. LP gas supply

pressure should be 11" to 13" w.c.

This pressure must be maintained

with all other gas fired appliances in

operation. The minimum supply

pressure to the gas valve for proper

furnace input adjustments is 5" w.c.

for natural gas, however 6" - 7" is

recommended. The minimum supply

pressure is 11" w.c. for LP gas.

A WARNING: NEVER PURGE

A GAS LINE INTO THE COMBUS-

TION CHAMBER. NEVER USE

MATCHES, FLAME OR ANY

IGNITION SOURCE FOR

CHECKING LEAKAGE. DOING

SO MAY RESULT IN FIRE,

EXPLOSION, PERSONAL INJURY

OR DEATH. To check for gas

leakage use an approved chloride-

free soap and water solution, an

electronic combustible gas detector

(see Figure 60), or other approved

method.

FIGURE 60

ELECTRONIC COMBUSTIBLE

GAS DETECTOR

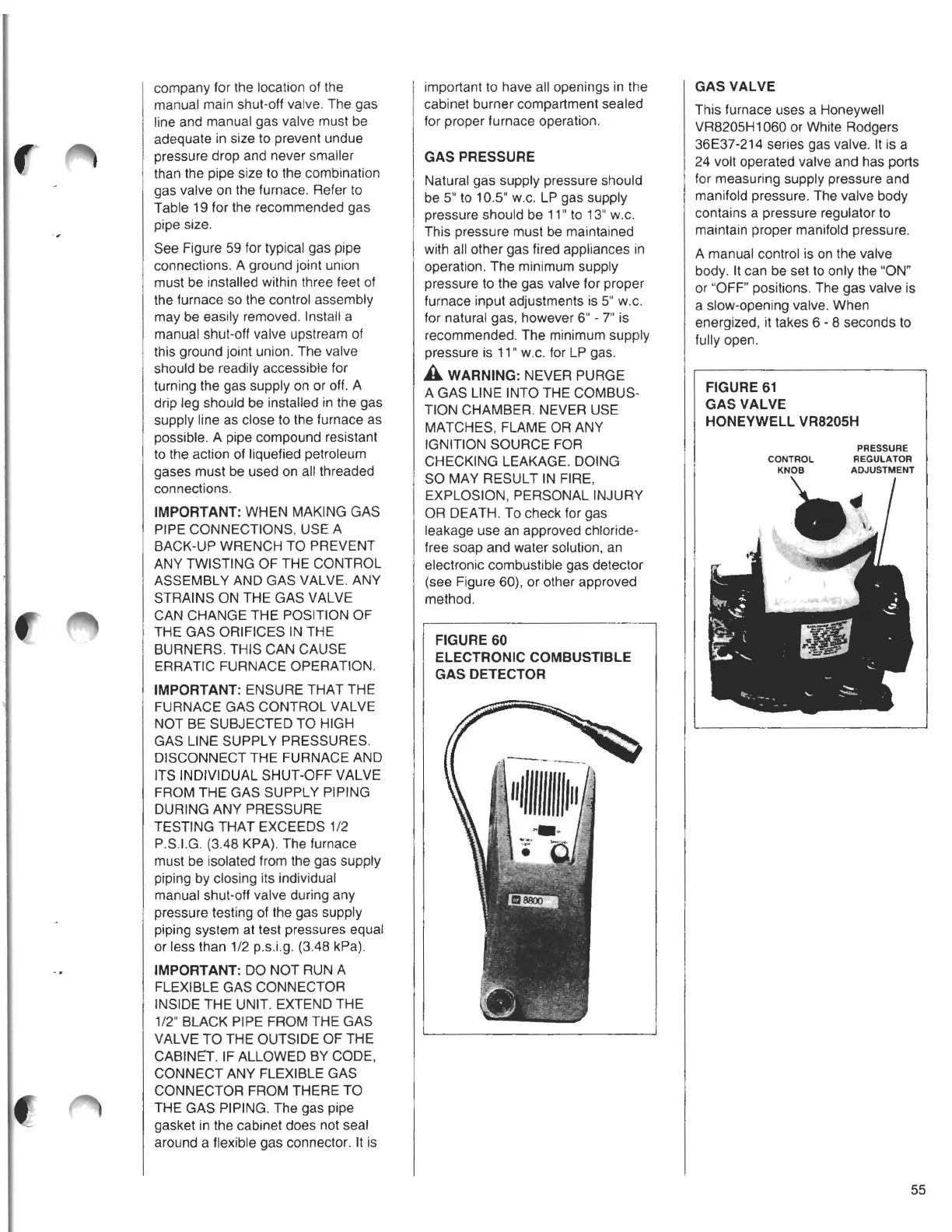

GAS VALVE

This furnace uses a Honeywell

VR8205H1060 or White Rodgers

36E37-214 series gas valve. It is a

24 volt operated valve and has ports

for measuring supply pressure and

manifold pressure. The valve body

contains a pressure regulator to

maintain proper manifold pressure.

A manual control is on the valve

body. It can be set to only the "ON"

or "OFF" positions. The gas valve is

a slow-opening valve. When

energized, it takes 6 - 8 seconds to

fully open.

FIGURE 61

GAS VALVE

HONEYWELL VR8205H

PRESSURE

CONTROL REGULATOR

KNOB ADJUSTMENT

•

55

Loading...

Loading...