LP CONVERSION

The valve can be converted to use

liquified petroleum (LP) gas by

replacing the pressure regulator

spring with the conversion kit spring.

This LP kit spring allows the

regulator to maintain the proper

manifold pressure for LP gas. The

correct burner LP orifices are also

included in the kit.

NOTE:Order the correct LP

conversion kit from the furnace

manufacturer.

Furnace conversion

to LP gas must be performed by a

qualified technician.

The furnace

LP kits are listed below.

TABLE20

LP KITS

FUELCOOE KITNO.

LOCATION

DC/OF EP80H

us.,0- 7999

DC/OF

FP-02

EP88H U.S , 8000' and Above

FP-03

DC /OF

EP81H

Canada.0 - 4500'

FP-05

EB/EC/EH IEJ

EBIEC/EH/EJ

FP-02

FP-03

U.S., 0 - 7999'

U.S., 8000' and Above

EB / EC/ EH / EJ

FP-05

Canada.O - 4500'

EK/EL

EK/EL

FP-02

FP-03

U.S.. 0 7999'

U.S., 8000' and Above

EK/ EL FP-05

Canada,O - 4500'

To change orifice spuds for either

conversion to LP or for elevation,

shut off the manual main gas valve

and remove the gas manifold.

Replace the orifice spuds and

reassemble in reverse order. Consult

Table 21 if there is any question

concerning orifice sizing.

TABLE21

ORIFICE SIZES

U.S.

0 - 8000 FT. 8001 FT. & ABOVE

Nat'I Gas #50 #51

LP Gas

115mm 1.10 mm

CANADIAN 0-2000 FT. 2001• 4500 FT.

Nat'IGas #50 #50

LP Gas 1.15mm

U5mm

,

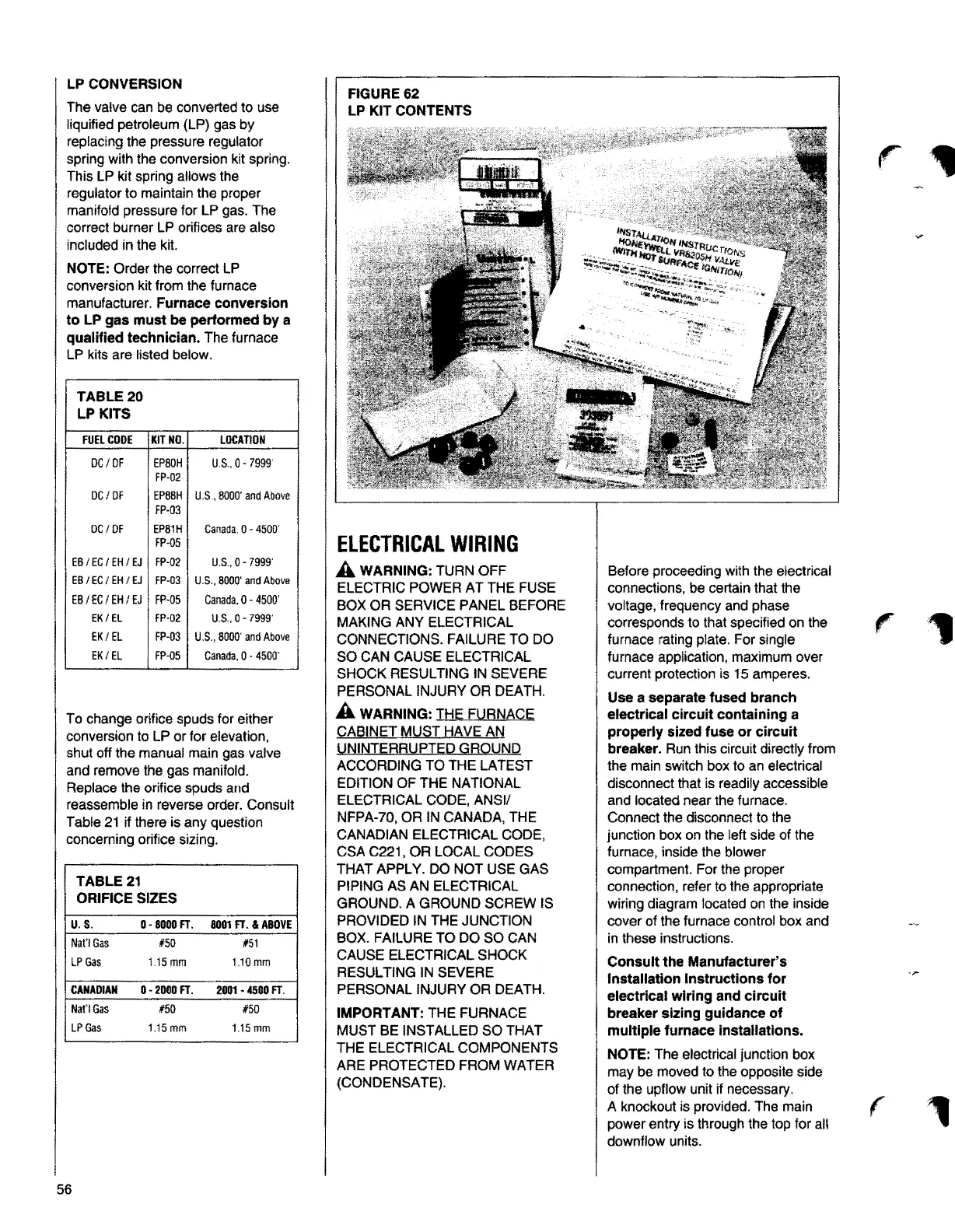

FIGURE62

LP KIT CONTENTS

ELECTRICALWIRING

A WARNING:TURN OFF

ELECTRIC POWER AT THE FUSE

BOX OR SERVICE PANEL BEFORE

MAKING ANY ELECTRICAL

CONNECTIONS. FAILURE TO DO

SO CAN CAUSE ELECTRICAL

SHOCK RESULTING IN SEVERE

PERSONAL INJURY OR DEA TH.

A WARNING:THE FURNACE

QA8!NET MUST t!AVE AN

!,JNINTERRUPTEIJ GRQUND

ACCORDING TO THE LATEST

EDITION OF THE NATIONAL

ELECTRICAL CODE,

ANSI/

NFPA-70, OR IN CANADA, THE

CANADIANELECTRICAL CODE,

CSA C221, OR LOCAL CODES

THAT APPLY. DO NOT USE GAS

PIPING

AS AN ELECTRICAL

GROUND. A GROUND SCREW IS

PROVIDED IN THE JUNCTION

BOX. FAILURE TO DO SO CAN

CAUSE ELECTRICAL SHOCK

RESULTING IN SEVERE

PERSONAL INJURY OR DEATH.

IMPORTANT:THE FURNACE

MUST BE INSTALLED SO THAT

THE ELECTRICAL COMPONENTS

ARE PROTECTED FROM WATER

(CONDENSATE).

Before proceeding with the electrical

connections, be certain that the

voltage, frequency and phase

corresponds to that specified on the

furnace rating plate. For single

furnace application, maximum over

current protection is 15 amperes.

Use a separate fused branch

electrical circuit containing a

properly sized fuse or circuit

breaker.

Run this circuit directly from

the main switch box to an electrical

disconnect that is readily accessible

and located near the furnace.

Connect the disconnect to the

junction box on the left side of the

furnace, inside the blower

compartment. For the proper

connection, refer to the appropriate

wiring diagram located on the inside

cover of the furnace control box and

in these instructions.

Consult the Manufacturer's

Installation Instructions for

electrical wiring and circuit

breaker sizing guidance of

multiple furnace installations.

NOTE:

The electrical junction box

may be moved to the opposite side

of the upflow unit if necessary.

A knockout is provided. The main

power entry is through the top for all

downflow units.

r

r

r

,

56

Loading...

Loading...