UPFLOW UNIT RETURN AIR

Construct a bottom return air system

to come up through the floor under

the furnace with a direct connection

made to the bottom of the furnace,

For installations where return air

'

""

ducts cannot run under the floor,

connect the return air duct to the side

or rear as required. Side or rear

return air cabinets are available from

the manufacturer.

If side, or rear, air return is used,

determine the opening size required

and mark a line between the

knockout squares. Cut an opening

along these lines.

NOTE: Ensure that any loose pieces

of insulation are removed from the

blower compartment. Do not allow

any insulation pieces to be drawn

into the blower wheel.

IMPORTANT:WHERE THE

MAXIMUM AIR FLOW IS 1800 CFM

OR MORE, BOTH SIDES OR THE

BOTTOM MUST BE USED FOR

RETURN AIR.

A WARNING:THE SOLID METAL

,

,.,

BASE PLATE MUST BE IN PLACE

WHEN THE FURNACE IS

INSTALLED WITH SIDE OR REAR

RETURN AIR DUCTS. REMOVING

THE BASE PLATE COULD CAUSE

PRODUCTS OF COMBUSTION TO

CIRCULATE INTO THE LIVING

SPACE CREATING POTENTIALLY

HAZARDOUS CONDITIONS,

INCLUDING CARBON MONOXIDE

POISONING.

NOTE:

Install upflow units in the

upf!ow position only.

A WARNING:NEVER OPERATE

THE BLOWER OR BURNERS

WITHOUT THE BLOWER DOOR IN

PLACE. FLUE GAS CAN BE

DRAWN INTO THE LIVING AREAS

POSSIBLY RESULTING IN

CARBON MONOXIDE POISONING,

PERSONAL INJURY OR DEATH.

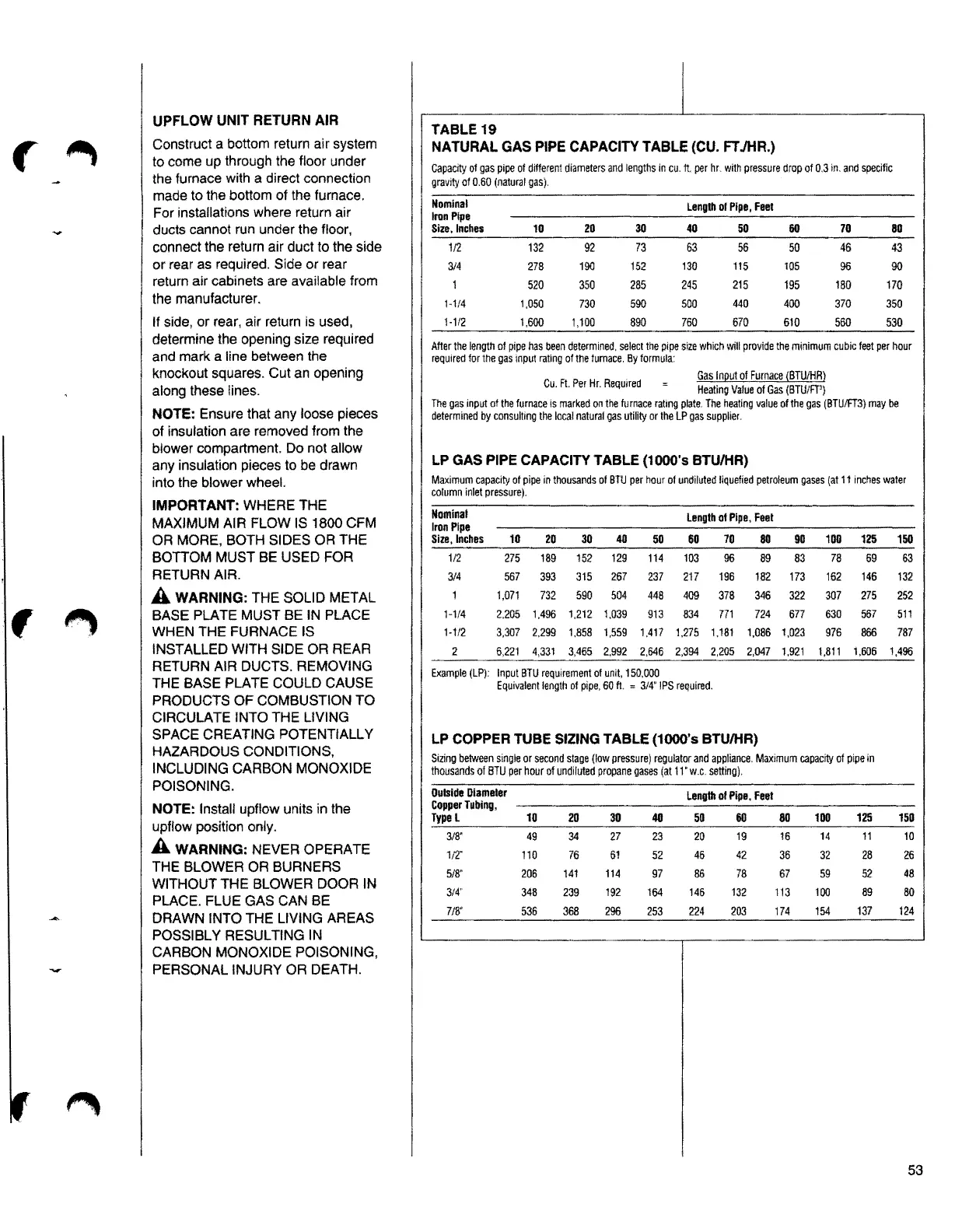

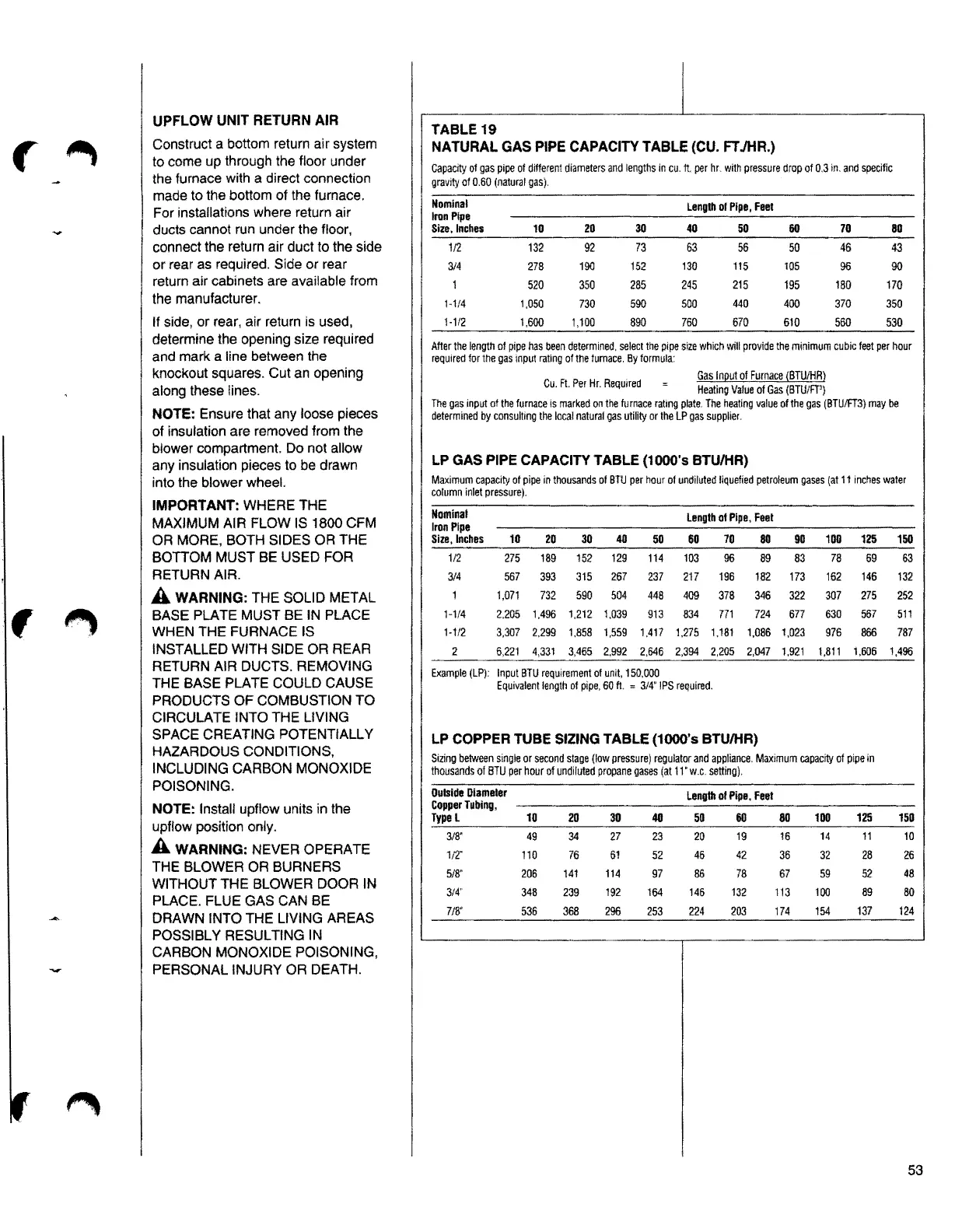

TABLE19

NATURAL GAS PIPE CAPACITY TABLE (CU. FT JHR.)

Capacityof gas pipe of different diametersand lengths in cu, ft per hr. with pressure drop of 0.3in. and specific

gravity ol

0.60(naturalgas).

Nominal

Length

ofPipe, Feet

Iron Pipe

Size. Inches 10 20 30 40 50 60 70

80

1/2 132

92

73

63

56 50

46

43

314 278 190 152

130 115 105

96

90

520 350 285

245 215 195 180 170

H/4 1,050

730 590 500

440 400 370

350

1-1/2

1.600

1,100

890

760 670 610

560 530

After the length of pipe has been determined, select the pipe size which will provide the minimum cubic feet per hour

requiredfor the gas input rating of the furnace, By formula:

Gas 1n11ut 1BTU/HR)of Furnace

Cu, Ft Per Hr. Required

HeatingValue of Gas (BTU/fl')

The gas input of the furnace is marked on the furnace rating plate, The heating value of the gas (BTU/FT3) may be

determinedby consulting the local natural gas utility or the LP gas supplier.

LP GAS PIPE CAPACITY TABLE (1000's BTU/HR)

Maximumcapacityof pipe in thousands of BTU per hour of undiluted liquefiedpetroleumgases(at11incheswater

column inlet pressure),

Nominal

Iron Pipe

Length of Pipe, Feet

Size, Inches

10 20 30

40

50

60

70

80 90 100

125

150

1/2 275 189 152 129 114

103

96 89 83

78

69 63

3/4 567 393 315 267 237 217 196 182 173 162 146 132

1 1,071 732 590 504 448

409 378 346

322 307

275 252

1-1/4 2,205

1.496

1,212 1,039

913

834

771

724 677 630 567 511

1-112

3,307 2,299 1,858 1,559

1,417

1,275 1,181 1,086 1,023

976

866

787

2 6,221 4,331 3,465

2.992 2,646 2,394

2,205 2,047 1,921 1,811

1,606

1,496

Example(LP): Input BTU requirement of unit, 150,000

Equivalentlength of pipe, 60ft. = 3/4"IPS required,

LP COPPER TUBE SIZING TABLE (1000's BTU/HR)

Sizing between singleor second stage (low pressure) regulatorand appliance, Maximumcapacityof pipe in

thousandsof BTU per hour of undiluted propanegases (at

11 • w.c. setting),

OutsideOiameler

CopperTubing,

Lengthol Pipe, Feel

TypeL 10

20 30 411 50 60 80

100

125 150

3/8'

49

34 27

23 20

19 16 14 11 10

1/2"

110 76 61 52

46 42 36 32 28 26

518"

206

141 114

97

86 78 67 59 52

48

3/4'

348 239

192

164

146 132

113 100

89

80

7/8'

536

368

296 253

224

203 174 154

137 t24

53

Loading...

Loading...