--

"

CONCENTRIC HORIZONTAL VENT

hole. (3 inch pipe must be glued

KIT • RXGY • C01

to "Y" at this point, using PVC

This termination kit is for horizontal

primer and cement which

venVintake air runs and may be

conforms to ASTM D2564.)

located where 12 in. clearance 3.

From the outside, connect the

above ground level or anticipated

4 x 3 in. coupling to the inlet

snowfall can be maintained. It is pipe, using PVC primer and

coaxial requiring only one wall

cement which conforms to

penetration and is adaptable for

ASTM D2564. Be sure that the

walls up to 16 in. thick. No revision is pipe is seated in the coupling.

required for thinner walls unless

4.

Push the coupling against the

there is an installation problem. The

wall and orient the assembly so

following parts are included:

that the inlet connection to the

1.

Vent, inlet wye and inlet pipe

wye is higher than the vent

assembly.

connection. This will prevent any

2.

4 x 3 in. coupling.

moisture from running down the

3.

3 in.

x45 degree street elbow.

inlet pipe to the furnace. Caulk

around the coupling at the

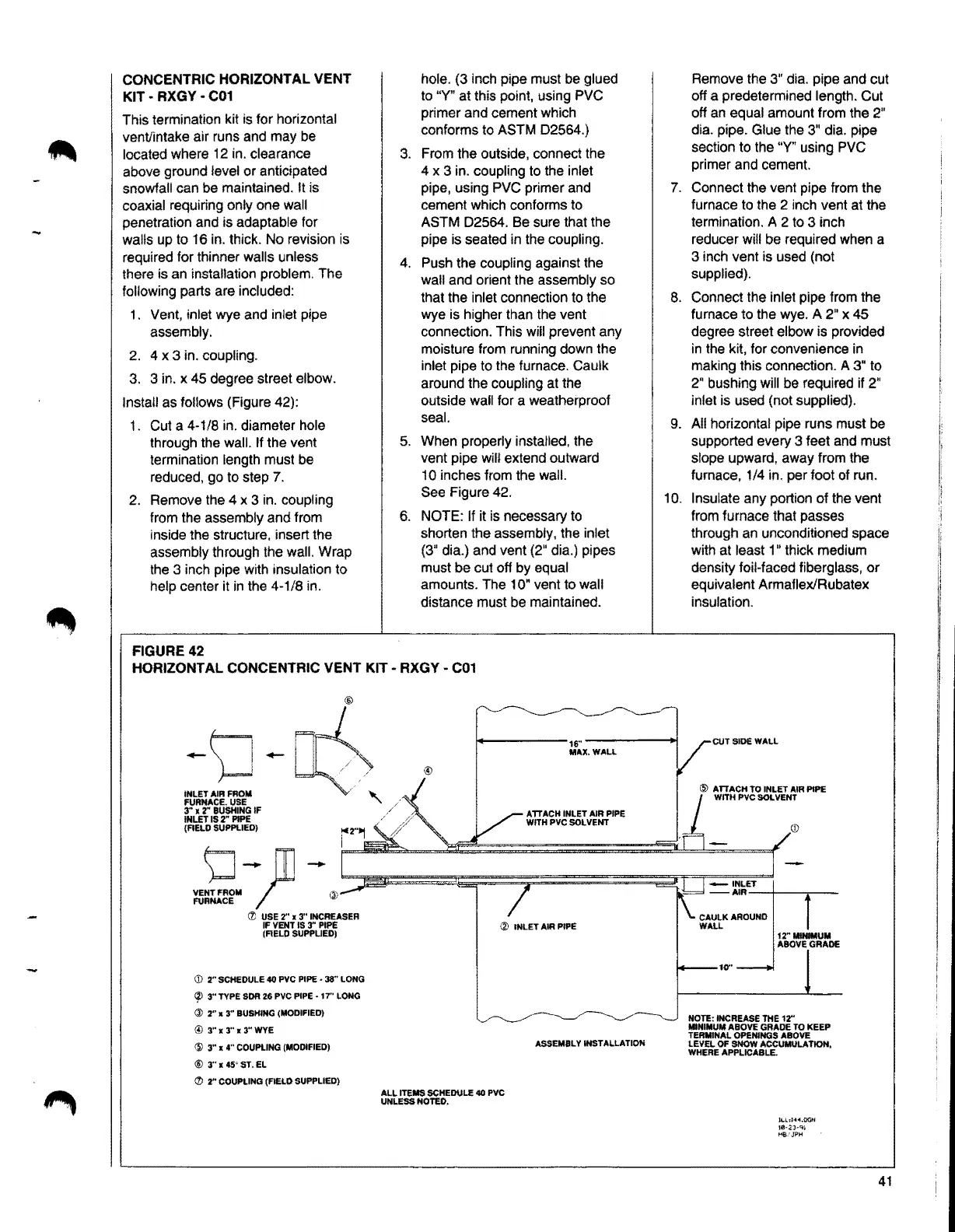

Install as follows (Figure 42):

outside wait for a weatherproof

i. Cut a 4-1/8 in. diameter hole

seal.

through the wall. If the vent

5. When properly installed, the

termination length must be

vent pipe will extend outward

reduced, go to step 7.

i Oinches from the wall.

2.

Remove the 4 x 3 in. coupling

See Figure 42.

from the assembly and from

6. NOTE: If it is necessary to

inside the structure, insert the

shorten the assembly, the inlet

assembly through the wall. Wrap

(3" dia.) and vent (2" dia.) pipes

the 3 inch pipe with insulation to

must be cut off by equal

help center it in the 4-1/8 in.

amounts. The 1

O"vent to wall

distance must be maintained.

FIGURE42

HORIZONTAL CONCENTRIC VENT KIT· RXGY • C01

-

INLET AIR FROM

FURNACE.USE

3"

x2" BUSHING IF

INLET IS 2" PIPE

(FIEt.D SUPPLIED)

-

- rn-

~~~~fM

r @

@

(t USE 2" x3" INCREASER

IF VENT IS 3" PIPE

(FIELD SUPPLIED!

(D 2" SCHEDULE 40 PVC PIPE • 38" LONG

~ 3" TYPE SOIi 26 PVC PIPE • 17" LONG

@ 2" x 3" BUSHING (MODIFIED)

@ 3"x3"x3"WYE

@ 3" x 4" COUPLING (MODIFIED)

@ 3"x45'ST.EL

(l) 2" COUPLING (FIEI.D SUPPLIED)

16"

MAX.WALL

ATTACH INLET AIR PIPE

WITH PVC SOLVENT

(Zi INLET AIR PIPE

ALL ITEMS SCHEDULE 40 PVC

UNLESS NOTEO.

ASSEMBLY INSTALLATION

7.

8.

9.

10.

Remove the 3" dia. pipe and cut

off a predetermined length. Cut

off an equal amount from the 2"

dia. pipe. Glue the 3" dia. pipe

section to the "Y" using PVC

primer and cement.

Connect the vent pipe from the

furnace to the 2 inch vent at the

termination. A 2 to 3 inch

reducer will be required when a

3 inch vent is used (not

supplied).

Connect the inlet pipe from the

furnace to the wye.

A 2" x 45

degree street elbow is provided

in the kit, for convenience in

making this connection.

A 3" to

2" bushing will be required if 2"

inlet is used (not supplied).

All horizontal pipe runs must be

supported every 3 feet and must

slope upward, away from the

furnace, 1/4 in. per foot of run.

Insulate any portion of the vent

from furnace that passes

through an unconditioned space

with at least 1 " thick medium

density foil-faced fiberglass, or

equivalent Armaflex/Rubatex

insulation.

CUT SIDE WALL

@ ATTACH TO INLET

AIR PIPE

WITH PVC SOL VENT

(D

-INLET

-AIR--4----

CAULK AROUND

WAl.L

10"

NOTE: INCREASETHE 12"

MINIMUMABOVE GRADE TO KEEP

TERMINAL OPENINGS ABOVE

LEVEL OF SNOW ACCUMULATION,

WHERE APPLICABLE.

k.L.!'4

◄

.0GN

U:l·2P'H

1"i6.7JPH

41

Loading...

Loading...