VENTING

EXHAUST PIPE TERMINATIONS

Standard vertical terminations

Vertical through-the-roof applications

r

do not require an exhaust terminal.

1. The exhaust vent must

terminate at least 12 inches

above the intake air termination.

The exhaust vent termination

for 90,000 - 120,000 BTUH

input models is 2 inch

PVC pipe.

2. Reduce the exhaust vent

termination for 45,000 - 75,000

BTUH input furnaces from

2 inches to 1-1/2 inches at the

air intake level. Extend this

1-1/2 Inch pipe 12 inches

beyond the air intake.

See Figure 40.

Standard horizontal terminations

For direct vent systems, the standard

termination is 2" PVC pipe extending

12• from the wall for furnaces with

inputs of 90,000 -120,000 BTU.

1. Install a 2" coupling at the

outside wall to prevent the

termination from being pushed

inward.

2. When 3" pipe is used between

the furnace and outside wall,

reduce the 3" pipe to 2" before

penetrating the wall. Extend the

2" pipe 12" past the outside wall.

For 45,000 - 75,000 BTUH input

furnaces, the standard termination is

1-1/2" PVC pipe extending outward

12" from the wall.

1. Install a 2" to 1-1 /2" coupling at

the outside wall to prevent

pushing the termination back

into the wall. See Figure 41,

Detail

8.

2. Install a length of 1 • 1 /2" pipe so

that it extends 12" beyond the

outside wall.

The exhaust termination must be at

least 12" above grade and must be

positioned with respect to the air

intake as shown in Figure 41,

Detail C. Refer to the section on

alternate venting options when

higher snow levels are anticipated.

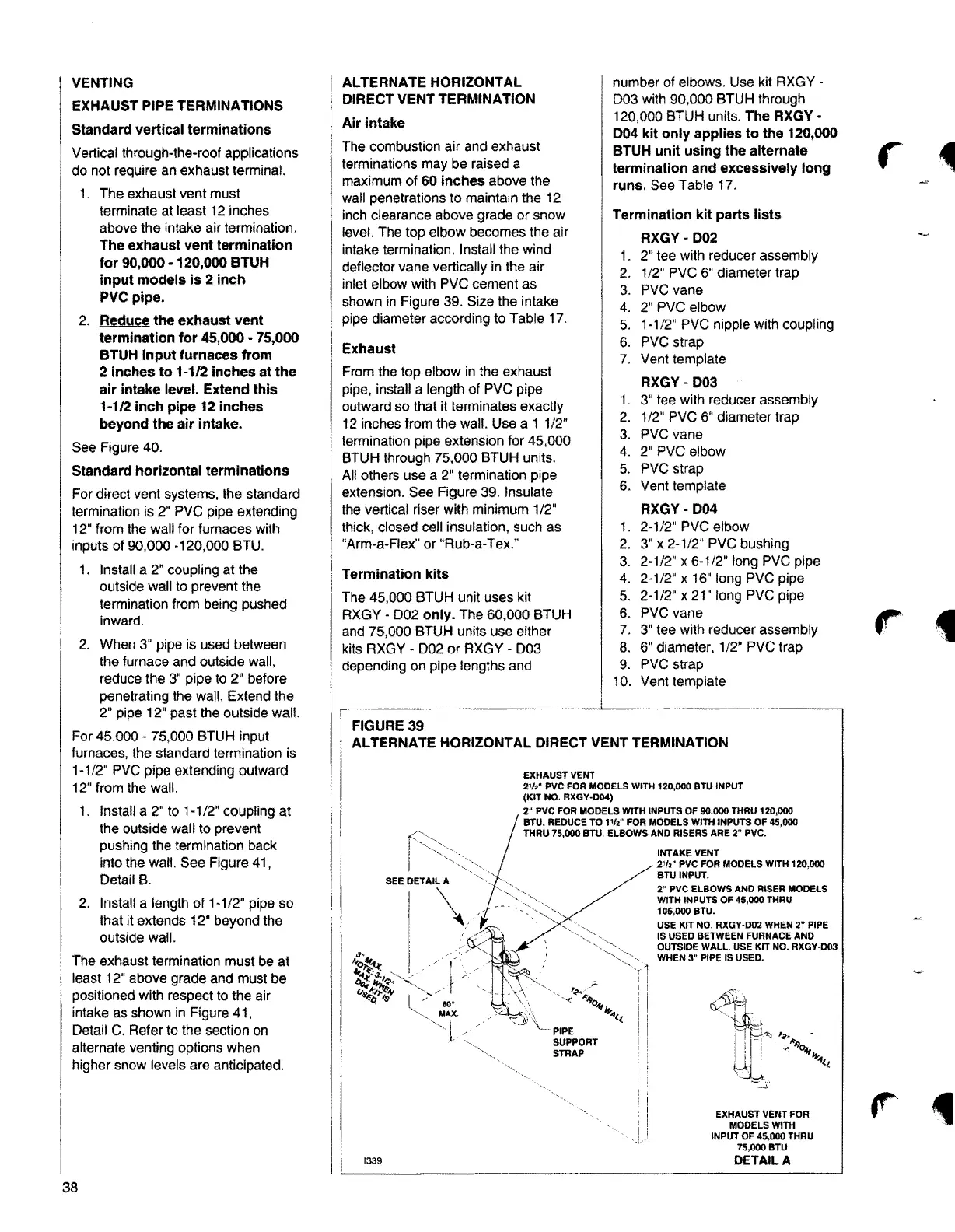

ALTERNATE HORIZONTAL

DIRECT VENT TERMINATION

Air intake

The combustion air and exhaust

terminations may be raised a

maximum of

60 Inches above the

wall penetrations to maintain the 12

inch clearance above grade or snow

level. The top elbow becomes the air

intake termination. Install the wind

deflector vane vertically in the air

inlet elbow with PVC cement as

shown in Figure 39. Size the intake

pipe diameter according to Table 17.

Exhaust

From the top elbow in the exhaust

pipe, install a length of PVC pipe

outward so that it terminates exactly

12 inches from the wall. Use a 1 1/2"

termination pipe extension for 45,000

BTUH through 75,000 BTUH units.

AUothers use a 2" termination pipe

extension. See Figure 39. Insulate

the vertical riser with minimum 1 /2"

thick, closed cell insulation, such as

"Arm-a-Flex" or "Rub-a-Tex."

Termination kits

The 45,000 BTUH unit uses kit

RXGY - 002

only. The 60,000 BTUH

and 75,000 BTUH units use either

kits RXGY - 002 or RXGY - 003

depending on pipe lengths and

FIGURE 39

number of elbows. Use kit RXGY -

003 with 90,000 BTUH through

120,000 BTUH units.

The RXGY •

D04 kit only applies to the 120,000

BTUH unit using the alternate

termination and excessively long

runs.

See Table 17.

Termination kit parts lists

RXGY- D02

1. 2" tee with reducer assembly

2. 1/2" PVC 6" diameter trap

3. PVC vane

4. 2" PVC elbow

5. 1-1/2" PVC nipple with coupling

6. PVC strap

7. Vent template

RXGY- D03

1. 3" tee with reducer assembly

2. 1/2" PVC 6" diameter trap

3. PVC vane

4. 2" PVC elbow

5. PVC strap

6. Vent template

RXGY-D04

1. 2-1/2" PVC elbow

2. 3" x 2-1/2" PVC bushing

3. 2-1/2" x 6-1/2" long PVC pipe

4. 2-1/2" x 16'' long PVC pipe

5. 2-1 /2" x 21" long PVC pipe

6. PVC vane

7. 3" tee with reducer assembly

8. 6" diameter, 1/2" PVC trap

9. PVC strap

10. Vent template

ALTERNATE HORIZONTAL DIRECT VENT TERMINATION

60"

MAX.

i

j, /

1339

EXHAUST VENT

2¼" PVC FOR MODELS WITH 120,000 BTU INPUT

(KIT NO. RXGY•D04)

2• PVC FOR MODELS WITH INPUTS OF 90,000 THAU 120,000

BTU. REDUCE TO 1½" FOR MODELS WITH INPUTS OF 45,000

THRU 75,000 BTU, ELBOWS AND RISERS ARE 2" PVC.

PIPE

SUPPORT

STRAP

INTAKE VENT

2½" PVC FOR MODELS WITH 120,000

BTIJINPUT.

2" PVC ELBOWS AND RISER MODELS

WITH INPUTS OF 45,000 THRU

105,000 BTU.

USE KIT NO. RXGY-002 WHEN

2" PIPE

IS USED BETWEEN FURNACE AND

OUTSIDE WALL. USE KIT NO. RXGY-003

WHEN

3" PIPE IS USED.

EXHAUST VENT FOR

MODELS WITH

INPUT OF 45,000 THRU

75,000BTU

DETAILA

4

38

Loading...

Loading...