INSTALLATION GUIDELINES

All piping must be installed in

compliance with Part 7, Venting of

Equipment, of the latest edition of the

National Fuel Gas Code NFPA-54/

ANSI 2223.1, local codes or

ordinances and these instructions.

1. Vertical piping is preferred.

2. All horizontal piping must

slope upward from the furnace

a minimum of 1/4" per foot

of run.

3. All horizontal runs must be

supported at least every three

feet. No sags or dips are

permitted.

4. Use only long OR medium

sweep elbows. Use only long

sweep elbows exterior to the

building.

5. All piping between the furnace

and outside wall or roof is 2"

or 3" as specified in Table 17.

A. When using 3" pipe it must

be reduced to 2" before

penetrating the outside wall

or roof.

8. Use a maximum of 18" of 2"

pipe with 3" pipe systems

before penetrating the roof.

C. The 120,000 BTUH

model may require 2-1/2"

components, which come in

the RXGY - D04 Kit.

6. IMPORTANT: DO NOT COM-

MON VENT WITH ANY OTHER

APPLIANCE. DO NOT IN-

STALL PIPING IN THE SAME

CHASE OR CHIMNEY WITH A

METAL OR HIGH TEMPERA-

TURE PLASTIC PIPE FROM

ANOTHER GAS OR FUEL

BURNING APPLIANCE.

7. All vent runs through

unconditioned spaces where

below freezing temperatures are

expected should be insulated

with 1 " thick medium density foil

faced fiber glass, or equivalent

Rubatex/ Armaflex insulation.

8. The minimum vent and

combustion air pipe length is

5 feet.

NOTE: Extend the exhaust a

minimum of 18" vertically above the

cabinet before turning vent.

COMBUSTION AIR PIPE

solvent. See Figure 41, Detail

TERMINATIONS B, for vane location.

Standard vertical terminations If 3 inch pipe is used between the

furnace and outside wall, reduce it

Use two 2" 90° long sweep elbows

to 2 inch before penetrating the wall.

to keep the inlet pointed down

'

1

preventing rain entry. See Figure 40

for proper relationship of com~

bustion air to exhaust termination.

Standard Direct Vent Horizontal

Termination Construction

The standard horizontal intake air

termination for all models is a 2" PVC

coupling with a wind deflector vane

attached.

1. Extend the pipe 1-1/4" through

the wall.

2. Attach a PVC coupling at the

very outside of the wall.

3. Cut a 2-1/4" length of 2" PVC

pipe and connect one end to

another 2" PVC coupling.

4. Connect the other end of this 2"

PVC pipe to the coupling at the

wall. The outer coupling must

terminate 4 inches from the wall.

5. Attach the wind deflector

vane supplied with the

furnace vertically inside the

outer coupling with PVC

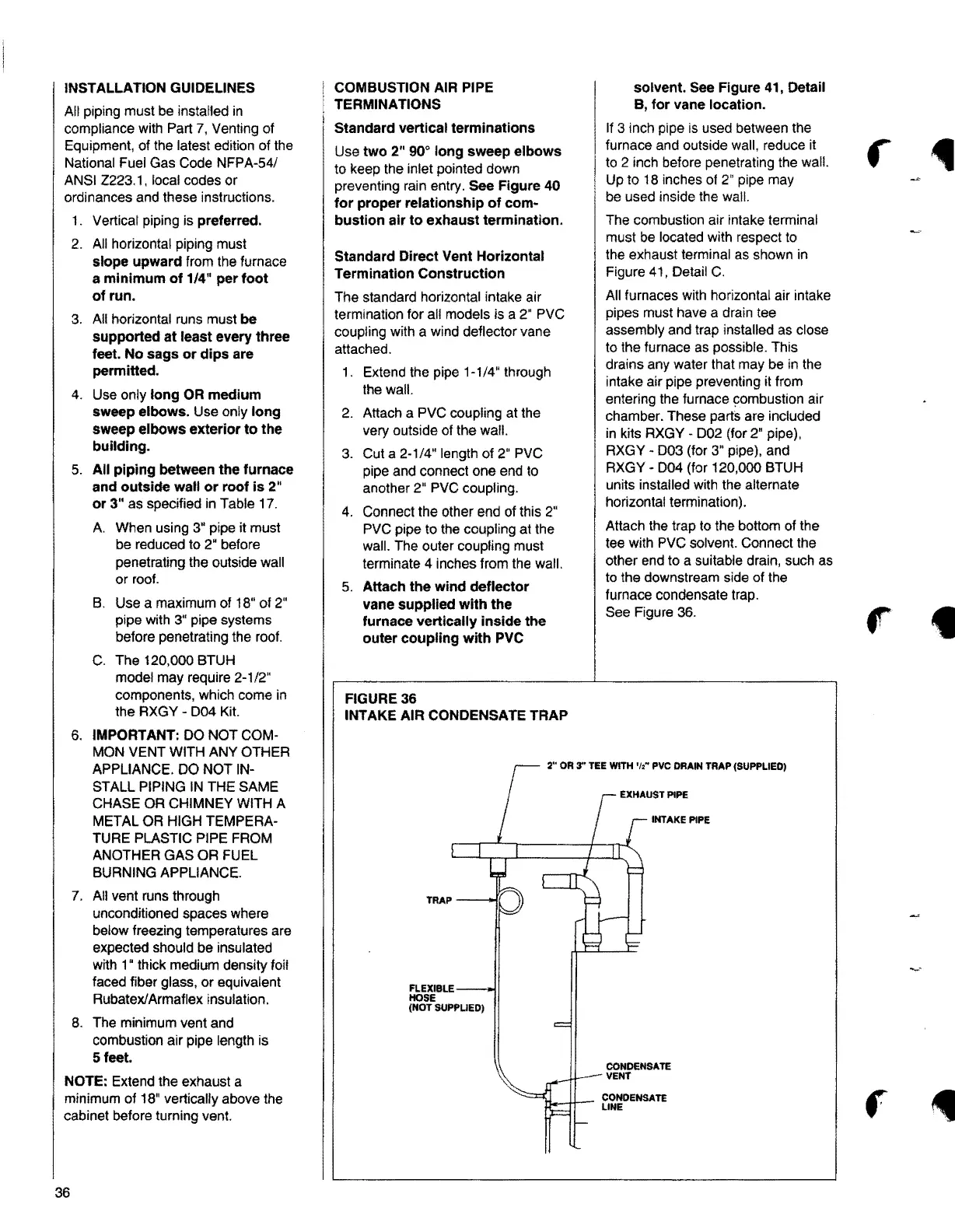

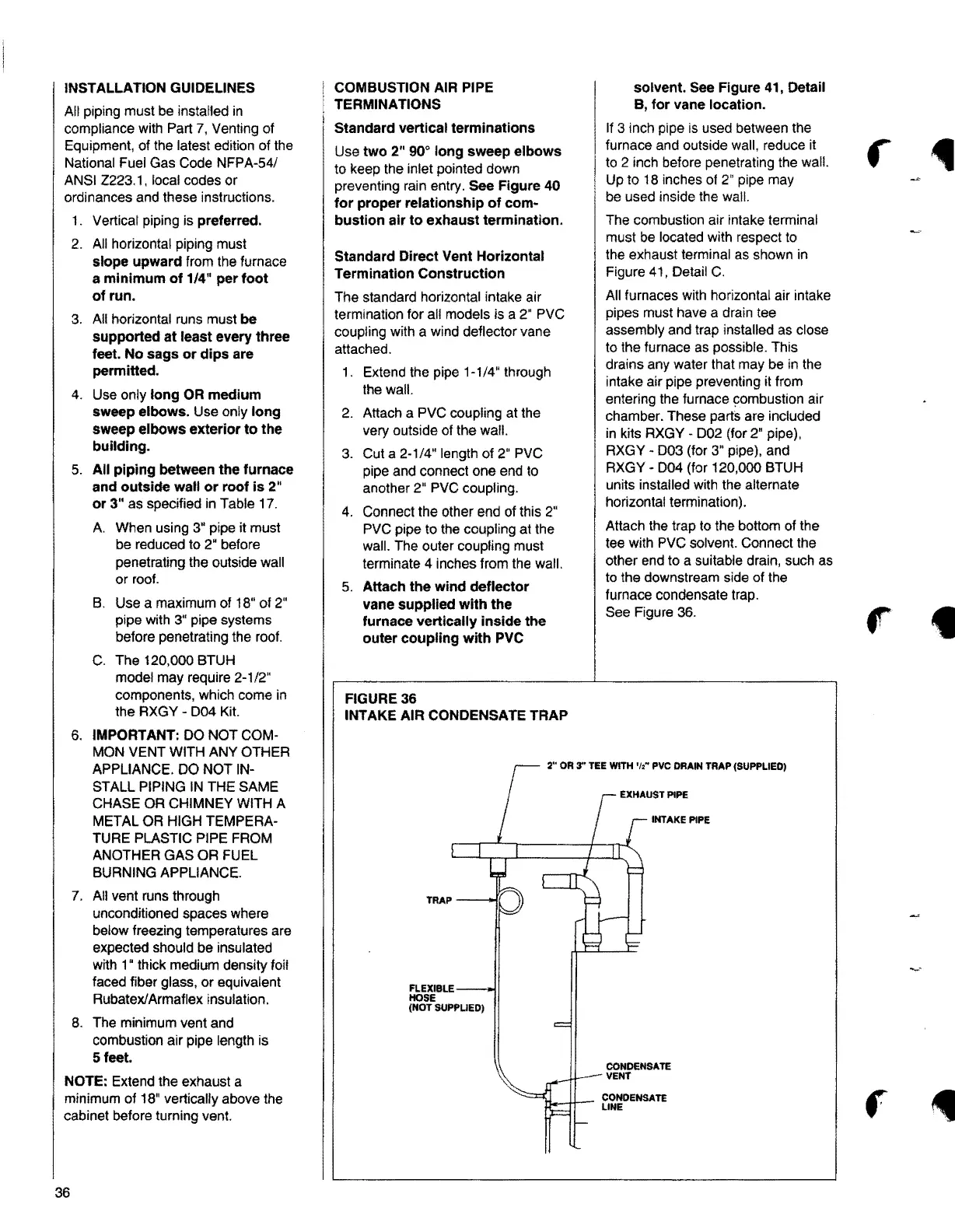

FIGURE36

INTAKE AIR CONDENSATE TRAP

Up to 18 inches of 2" pipe may

be used inside the wall.

The combustion air intake terminal

must be located with respect to

the exhaust terminal as shown in

Figure 41, Detail C.

All furnaces with horizontal air intake

pipes must have a drain tee

assembly and trap installed as close

to the furnace as possible. This

drains any water that may be in the

intake air pipe preventing it from

entering the furnace combustion air

chamber. These parts are included

in kits RXGY • D02 (for 2" pipe),

RXGY - D03 (for 3" pipe), and

RXGY - 004 (for 120,000 BTUH

units installed with the alternate

horizontal termination).

Attach the trap to the bottom of the

tee with PVC solvent. Connect the

other end to a suitable drain, such as

to the downstream side of the

furnace condensate trap.

See Figure 36.

2" OR 3"'TEE WITH 't,• PVC DRAIN TRAP (SUPPLIED)

TRAP

FLEXIBLE

HOSE

(NOT SUPPLIED)

INTAKE PIPE

CONDENSATE

VENT

l-L--+1--- f,i:DENSATE

t

f

36

Loading...

Loading...