Maintenance Manual SP 40

Rev. 005

85

Chapter 4

Service Maintenance

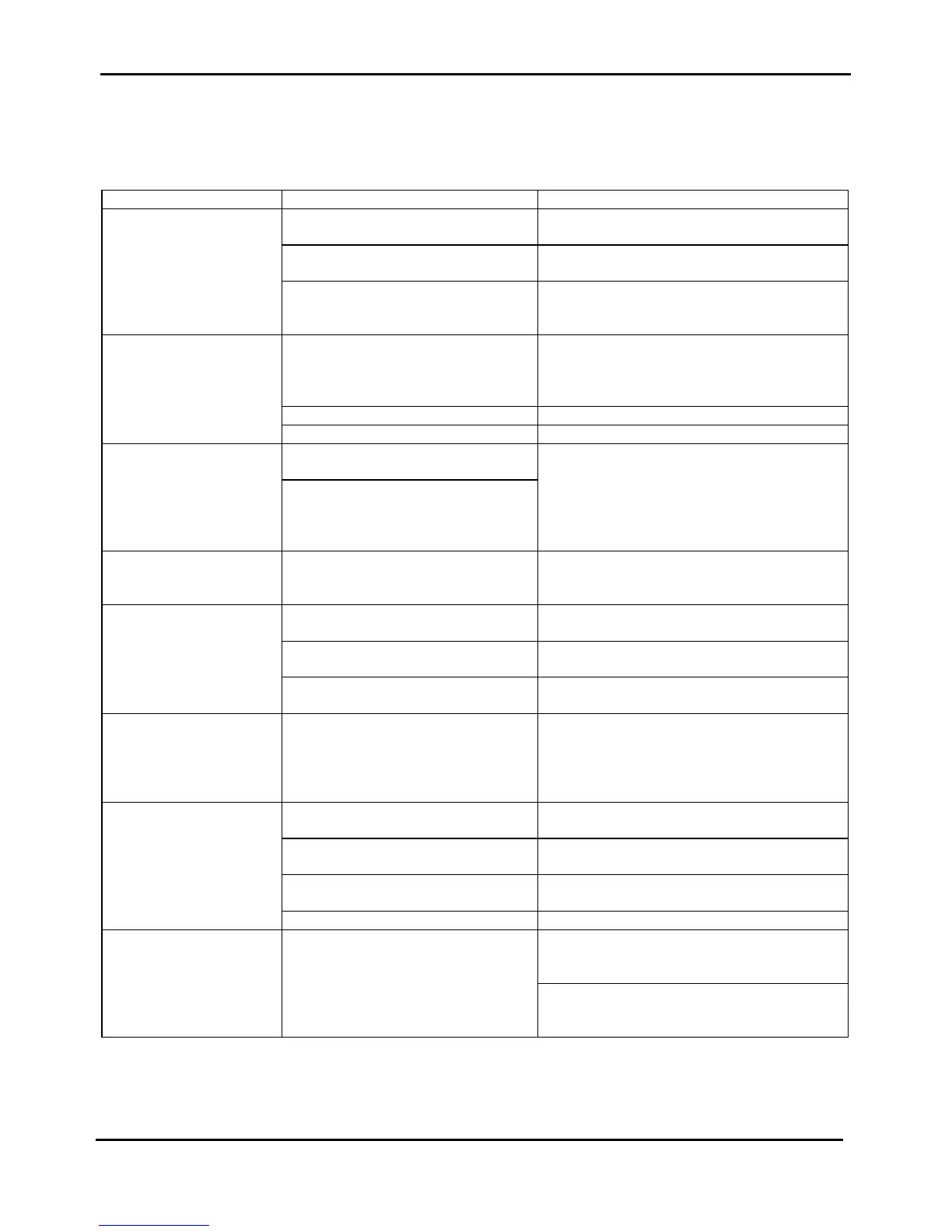

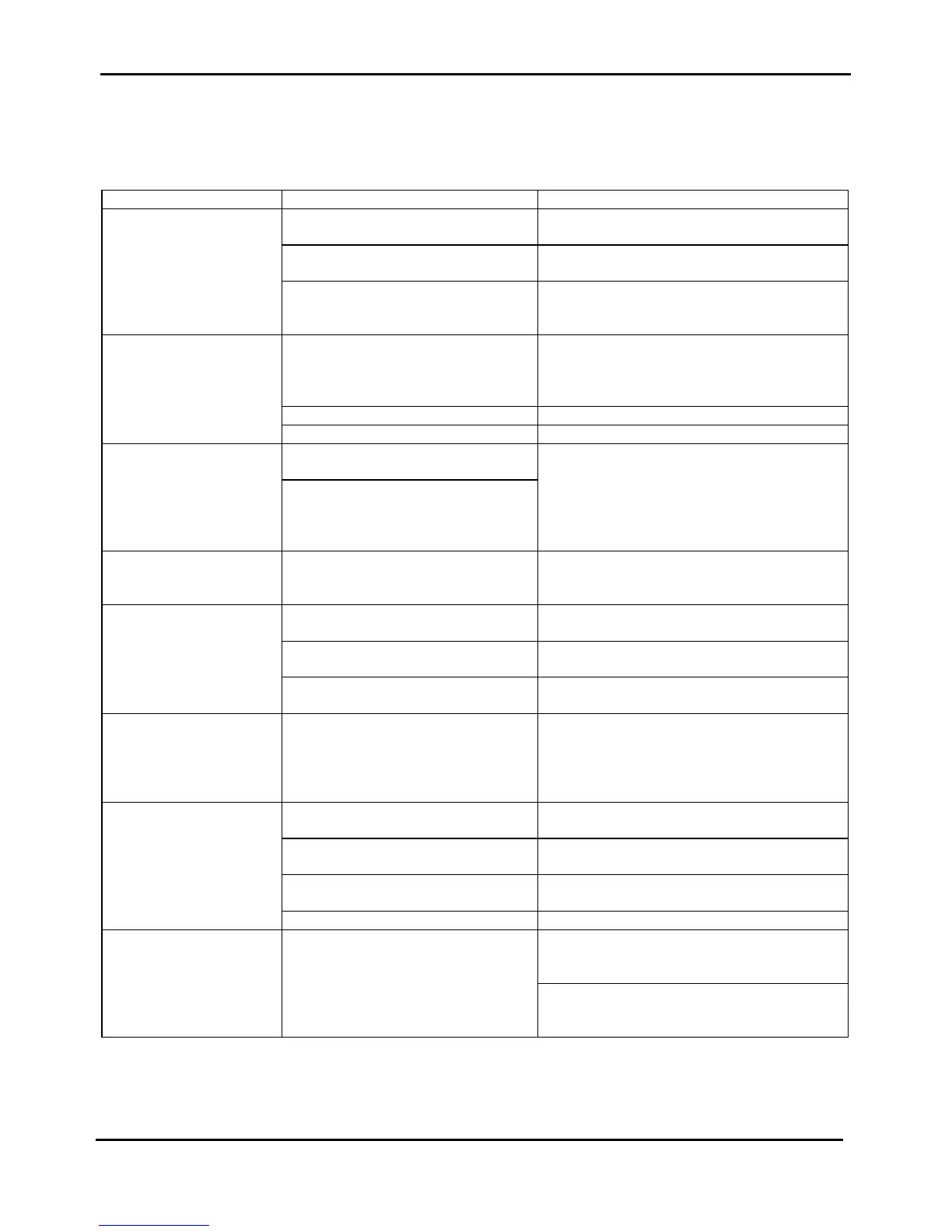

4.10.2 Faulty Probability Guide

This table resumes some (not all) of the most frequently symptoms of incorrect functionalities that can appear in the

normal usage of the printer with their related probable cause and the corrective actions.

SYMPTOM PROBABLE CAUSE CORRECTIVE ACTION

Inconsistent character

printing

The ribbon may not be correctly

installed

Re-install the inked ribbon cartridge.

The ribbon cartridge may be faulty

(check for its free movement)

Replace with a new one.

The ribbon does not work properly. Check for the correct movement of the Ribbon

Drive Assy.

Replace Ribbon Drive assy

Some dots are not printed The print head cables may be

incorrectly installed or damaged.

Run T&D10 to check the printout.

Check for the print head cables insertion on

p.h. and engine board.

Replace print head cables.

The print head may be faulty Check for coils impedance. Replace P.H.

The main board may be faulty. Replace engine board.

The printer stops printing The thermal sensor in the print head

may be faulty

Check the sensor resistance.

Replace P.H..

The connection between p.h. and

engine board is defective.

Check for the print head cable connection.

Replace p.h. cable.

The circuit on engine board may be

faulty.

Replace engine board.

The carriage doesn' t move

in a properly way.

The home position sensor may be

faulty.

Check for the correct insertion of sensor cable

Run T&D10 to checking.

Replace home position sensor..

The character printing are

vertical disaligned.

The printer may be not properly

adjusted.

Run T&D09 to readjust the vertical alignment.

The sensor edge may be not correctly

adjusted.

Run T&D09 to check edge sensor.

Replace edge sensor.

The ruby on print head is not installed

correctly.

Run T&D10 to verify.

Replace the print head.

The paper is loaded but

not correctly positioned

(skew).

The skew sensors does not work

properly.

Check for the skew sensors connection by the

optical fibre.

Run T&D09 to checking.

Replace sensor board or optical fibre.

Replace engine board.

The paper does not

advance properly.

The paper motor is not correctly

installed.

Check for paper motor connection on engine

board.

The paper motor may be faulty Check for its impedance.

Replace paper motor assy.

The paper belt tension is not properly

adjusted.

Check paper belt tension adj.

Readjust if it is need.

The paper is out of specifications Check for the paper specification to be correct.

The paper is loaded but

immediately ejected

The paper edge sensor does not work

properly.

Check edge connection on p.h.

Run T&D09 to check edge sensor.

Replace edge sensor assy.

Check for print head cable connection.

Replace prinr head cable.

Replace engine board.

Table 4.4 Faulty Probability Guide

Loading...

Loading...