62

Curtis 1232E/34E/36E/38E & 1232SE/34SE/36SE Manual, os 30

24 NOVEMBER 2015

3 — PROGRAMMABLE PARAMETERS: Motor Feedback Parameters

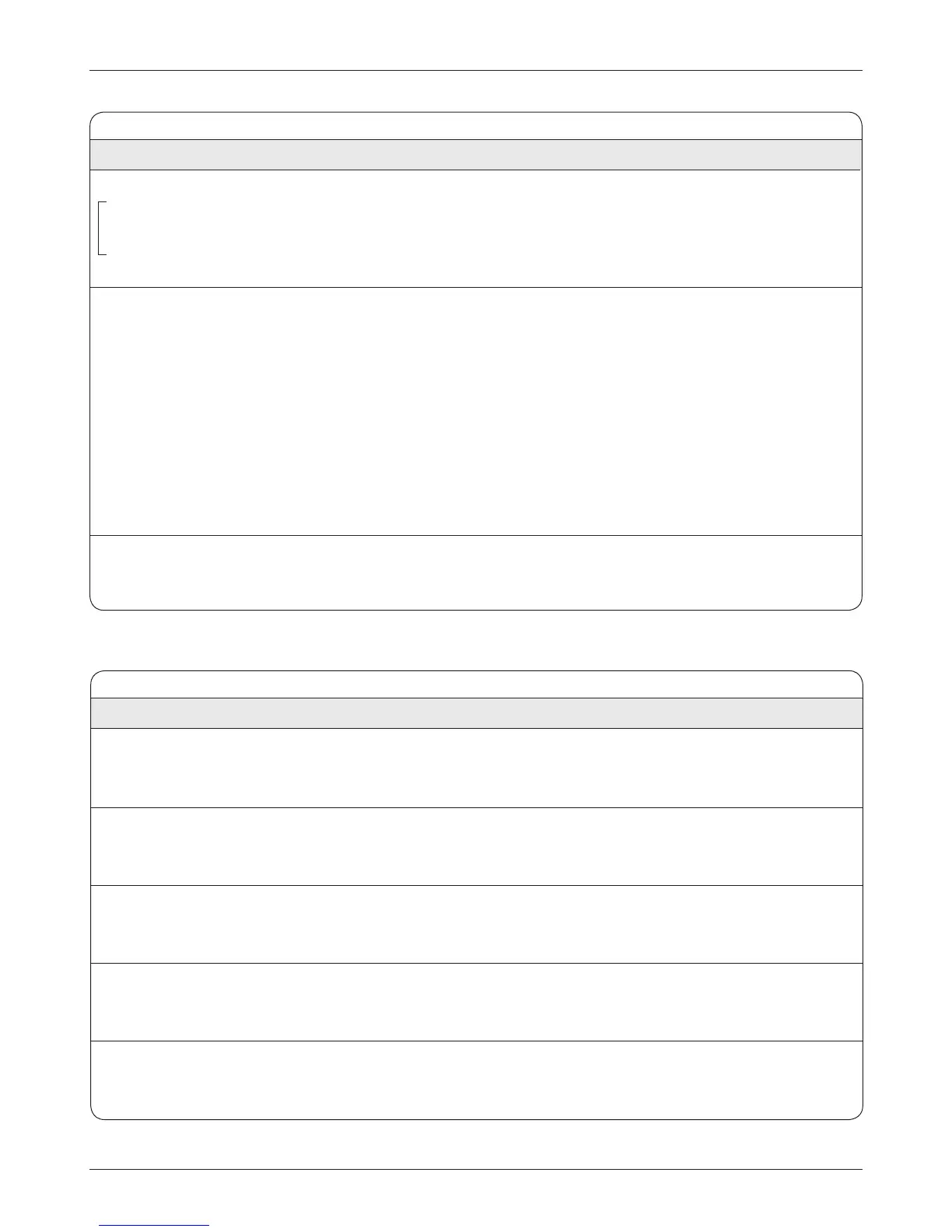

MOTOR FEEDBACK 2-SIN/COS MENU

ALLOWABLE

PARAMETER RANGE DESCRIPTION

Sin Cos Fault Threshold 5.0–20.0% DenestheallowablepercentchangeintheSinorCosfeedback.

Sin_Cos_Fault_Threshold 51 – 205 A Sin/Cos Sensor Fault (fault code 36) is declared if this threshold is

0x3878 0x00 exceededvetimessequentially.

Sin Min 0 – 1023 Minimum output by the Sin/Cos sensor on the Sin channel.

Feedback_Sin_Min 0 – 1023 Input detected at Position Feedback A (pin 31). The value is set

0x3863 0x00 duringtheSPMmotorcharacterizationprocedure.

Sin Max 0 – 1023 Maximum output by the Sin/Cos sensor on the Sin channel.

Feedback_Sin_Max 0 – 1023 Input detected at Position Feedback A (pin 31). The value is set

0x385C 0x00 duringtheSPMmotorcharacterizationprocedure.

Cos Min 0 – 1023 Minimum output by the Sin/Cos sensor on the Cos channel.

Feedback_Cos_Min 0 – 1023 Input detected at Position Feedback B (pin 32). The value is set

0x385F 0x00 duringtheSPMmotorcharacterizationprocedure.

Cos Max 0 – 1023 Maximum output by the Sin/Cos sensor on the Cos channel.

Feedback_Cos_Max 0 – 1023 Input detected at Position Feedback B (pin 32). The value is set

0x382F 0x00 duringtheSPMmotorcharacterizationprocedure.

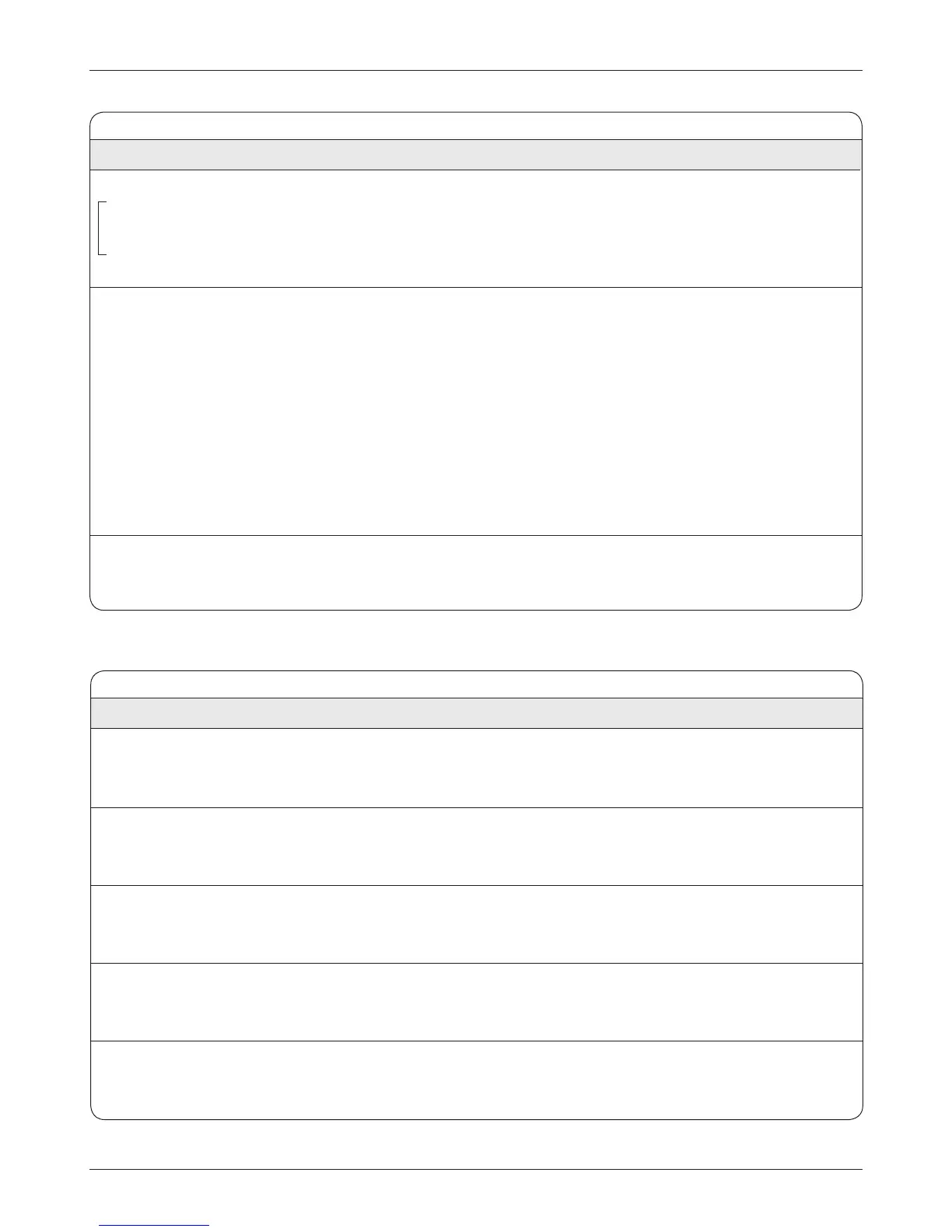

MOTOR FEEDBACK 1-ENCODER: ENCODER FAULT SETUP MENU

ALLOWABLE

PARAMETER RANGE DESCRIPTION

Fault Detection Enable On / Off When programmed On, encoder fault checking is enabled.

Encoder_Fault_Detection_Enable On / Off Three fault conditions are checked: Encoder Fault (fault code 36, Stall

Encoder_Fault_Detection_Enable_ Detected (fault code 73), and Encoder Pulse Error (fault code 88).

Bit0 [Bit 0]

0x389C 0x00

Encoder Pulse Fault Detect Time

0.0–3.0s Denestheminimumtimeittakesforthecontroller,whilethevehicleis

Encoder_Pulse_Fault_Detect_Time 0 – 94 in motion, to detect that the encoder and the Encoder Steps parameter do

0x393E 0x00 not match. When the Encoder Steps setup is incorrect, the motor

controllercannotproperlycalculateACmotoreldorientation.Thelossof

eldorientationcancausethemotortospinuptowardfullspeedonceany

throttle is applied.

This parameter sets a timer that starts once the throttle has been

movedandthenreleased,thedrivecurrentissignicant,andthemotor

is still accelerating. Note that the motor can spin at high rpm for several

seconds before conditions allow the controller to properly detect a fault.

An Encoder Pulse Error (fault code 88) is declared when this fault is

detected.

Settingtheparametertozerowilldisablethisfaultdetection.

Fault Stall Time 0 – 10 s Sets a timer when no motor encoder movement is detected. If no motor

Enc_Fault_Stall_Time 0 – 5000 encoder movement is detected for the programmed Fault Stall time, with

0x3089 0x00 maximum throttle applied, a Stall Detected fault (fault code 73) is issued.

Loading...

Loading...