Overview

User Manual xi

Overview

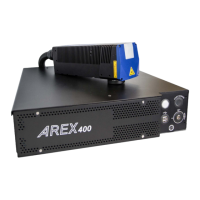

The Fiber laser marker developed and manufactured by Datalogic employs the

most advanced technologies with regards to the opto-mechanical parts, the

electronic control of laser beam power, communication and the overall safety of

the entire marker.

Laser Source

On Arex™ 400 laser marker it is used a sealed fiber laser source. This source is

based on the new fiber solid state technology. It guaranties high stability, lower

sensitivity to optical misalignment and a longer product lifetime.

Galvanometric scan head

The scan head features two deflection mirrors that deflect the beam in X and Y

directions, depending on the graphics/pattern to be reproduced.

Operation of a laser marker with galvanometric scanning

During the marking the laser generates an invisible, high-energy infrared beam.

In order to obtain a more accurate focus,

the laser beam is first enlarged using

an optical expansion system and then deflected by a scanning system consisting

of two mirrors mounted on galvanometric motors.

These mirrors deflect the beam in a controlled path along the

X and Y axes; pro-

cessing of the product surface occurs by coordinating the movement of the two

m

irrors and the turning on/off of the laser beam.

The deflected laser beam is focused by an F-Th

eta scan lens on the surface of

the product.

Generally speaking, the marking is carried out within the focus plane of the F-

Th

eta scan lens.

Marking Software

The Ligther™ marking software is preinstalled on the product.

NOTE

NOTE

W

ARNING

It is the responsibility of the customer to install the laser marker in proper safety con-

dition!

If necessary, consult “How to update the marking software” on page 118, to upgrade

the preinstalled software.

Consult Lighter™ software user's manual for a prope

r use of the same.

Loading...

Loading...