Technical Specifications

28

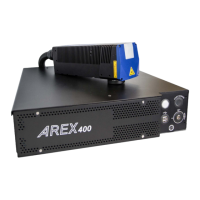

Arex™ 400

Command Box (Laser Control)

Control rack back panel connector

Socket Sub-D, 25 pins, female.

Figure 8: Command Box connector, female panel socket (front view)

PIN SIGNAL TYPE (***) DESCRIPTION

1 24V_ENABLE_B Output power supply Auxiliary 24V DC power supply available for

EXT_ENABLE_B

(max 125mA)

2 EXT_ENABLE_B Digital Input

Secondary external ENABLE signal:

- HIGH level: contact closed

- LOW level or disconnected: contact opened

3 GOOD/BAD Digital Output

This signal is used to notify a bad marking:

- ON in case of bad marking

4 EXT_24V Output power supply Auxiliary 24V DC power supply available for drive input logical HIGH (max 125mA)

5 EXT_24V Output power supply

Auxiliary 24V DC power supply available for drive input logical HIGH (max 125mA)

6 EXT_24V Output power supply Auxiliary 24V DC power supply available for drive input logical HIGH (max 125mA)

7 24V_ENABLE_A Output power supply

Auxiliary 24V DC power supply available for

EXT_ENABLE_A

(max 125mA)

8 EXT_ENABLE_A Digital Input

Primary external ENABLE signal:

- HIGH level: contact closed

- LOW level or disconnected: contact opened

9 BUSY Digital Output

This signal is used to know if the current

spooler is executing (marking in progress):

- ON during marking process

10 CONNECTOR_PRESENCE Digital Input

This signal is used to check the presence of the Command Box connector:

- HIGH level: normal operation

- LOW level or disconnected: laser marker faulty

11 START_MARKING (*) Digital Input

This signal is used to start to the marking process when a docum

ent or a sequence is run-

ning in AUTO MODE (**) or WORK MODE (**):

- HIGH level pulsed signal start the marking process

12 EXT_KEY Digital Input

External KEY signal:

- HIGH level: contact closed

- LOW level or disconnected: contact opened

13 STOP_MARKING (*) Digital Input

This signal is used to stop the marking process:

- HIGH level pulsed signal stop the marking process

14 RESERVED - DO NOT CONNECT

15 RESERVED -

DO NOT CONNECT

16 RESERVED - DO NOT CONNECT

17 END Digital Output

This signal is used to know if the marking process is finished:

- ON at the end of marking process

18 POWER_ON Digital Output

This signal is used to know if the laser marker is already warmed up:

- ON when the laser is in STAND_BY or READY state

19 GND Ground

Ground reference

20 SYSTEM_ALARM Digital Output

This signal is used to know if the laser marker is in booting up state or in error state:

- ON during BOOTING UP

- ON in case of system error

21 GND Ground

Ground reference

22 ENABLE_OUT Digital Output

This signal is used to know if the laser marker is ready to emit laser radiation:

- ON when the laser marker is in READY state

23 SW_READY (*) Digital Output

Depending on the configuration this signal can be used in different ways:

- COMPATIBILITY: ON when a document or a sequence is running in AUTO MODE (**) or

WO

RK MODE (**) independently from the laser marker state. The signal is ON regardless

of whether the laser marker is ready to start a new marking

- STANDARD: ON when a document or a sequence is running in AUTO MODE (**) or WORK

MOD

E (**) and the laser marker state is READY. The signal is ON regardless of whether

the laser marker is ready to start a new marking

- READY TO MARK: ON only when a document or a sequence is running in AUTO MODE (**)

o

r WORK MODE (**) and the laser marker state is READY. The signal is ON only if the laser

marker is ready to accept a new START_MARKING event (loading/spooling already exe-

cuted)

This signal can also be driven using Lighter™ Script engine "IoPort.setReady (true)" function

24 GND Ground Ground reference

25 GND Ground Ground reference

Table 2: Command Box connector pinout

(*) refers to Lighter™ user's manual “Setting I/O parameters” paragraph to set the signal properties

(**) refers to Lighter™ user's manual

(***) see “Input/Output specifications” on page 34

Loading...

Loading...