Understanding SLO: Safe Laser Off

90

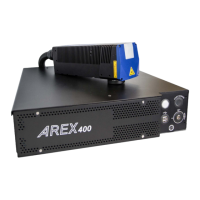

Arex™ 400

Example 2

Risk Analysis of a fully automatic laser processing machine that operates only

when protection system is disengaged.

• Operative cycle: 500 pcs/hour, 3 shifts

(8h/shift) 350 days /year

• Dedicated enclosures prevent laser emission also during parts loading /

un

loading

• An interlocked door is d

edicated to maintenance and blockage recovery

• Operator are NOT SK

ILLED on laser risks and do NOT have DPI

• In case of access line is

stopped and restarted

LASER RISK ASSESSMENT: H

AZARD, direct scattered laser radiation:

• RISK SEVERITY: SEVERE (irreversible eye damage)

• RISK FREQUENCY: SELDOM (1/week)

• AVOIDANCE PROBABILITY: NO

T POSSIBLE

RISK REDUCTION: INTELOCKED DOOR

Estimation of PLr for door

interlock safety function

• SEVERITY: SEVERE S2

• FREQUENCY: SELDOM F1

• POSSIBILITY OF AVOIDING HAZARD: NOT POSSIBLE P2

Severity of injury (S)

S1 Slight (normally reversible injury)

S2 Serious (normally irreversible injury or death)

Frequency and/or exposure time to hazard (F)

F1 Seldom to less often and/or exposure time is short

F2 Frequent to continuous and/or exposure time is long

Possibility of avoiding hazard or limiting harm (P)

P1 Possible under specific conditions

P2 Scarcely possible

PLr = PLd

Restart: manual reset

Door Switch

Safety Controller Arex™ 400 SLO - Safety Circuit

Input

Subsystem

Logic

Subsystem

Output

Subsystem

PLr=PLd

Loading...

Loading...