Chapter 6 Description of Operations

PAGE 6-9

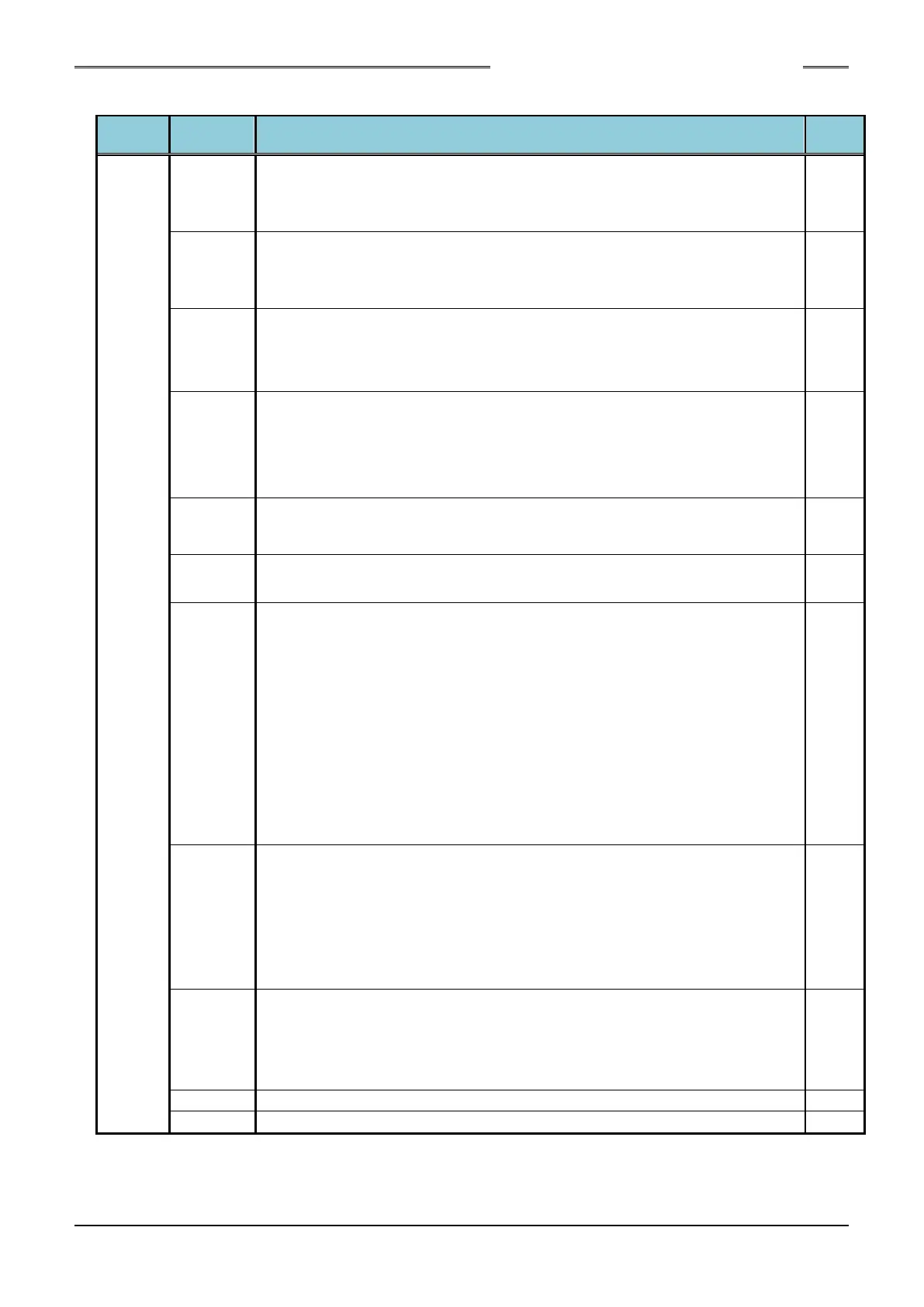

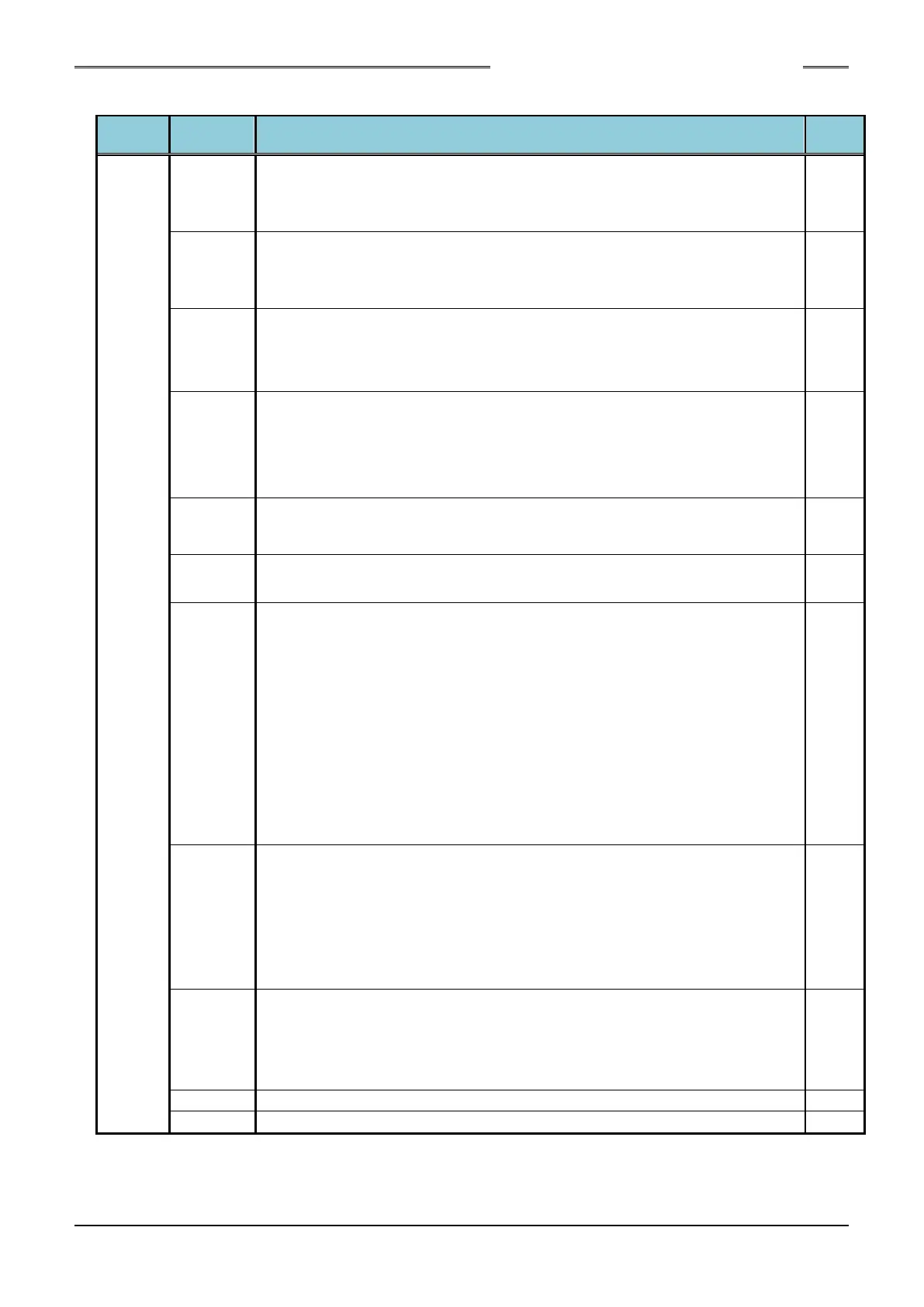

●List of Contents Indicated in the Real Time Mode(1/2)

[Torque Value Indication]

The load that is currently applied to the torque transducer is indicated in real

time. When the [CAL] switch is pressed, the torque value converted in

terms of the calibration torque is output.

[Torque Voltage Value Indication]

The torque signal voltage that is currently applied to the torque transducer is

indicated in real time. When the [CAL] switch is pressed, the torque

voltage is output in terms of a potential difference of approximately Δ3.75V.

[Maximum Torque Value Indication] (Maximum Torque Value Hold)

The peak torque from the point at which the [RESET] switch was pressed

last in the real time mode is indicated. Servo lock is performed for 1

minute when the [SET] switch is pressed.

[Rotating Angle Indication]

The angle of rotation from the current position is indicated in real time.

When the RESET signal is set to “ON” or when the fastening operation is

started by the OFF → ON raising of the START signal, the angle value

becomes 0.

[Load Rate]

The current motor load rate is indicated in real time. When 100 is

exceeded, Abn. 08-10 “Overload Error” is generated.

[Current Value]

The present current value is indicated in real time.

[Simplified I/O Monitor]

When SW2: Pin No. 6 at the bottom surface of the Unit is ON, the indication

will be as shown in the diagram below (IO-OFF) (external input/output

disabling function).

Ordinarily, the 12 bits of the standard DIO are monitored and indicated as

shown in the diagram below.

When the SET button is long-pressed, forced ON output is performed (at 0.5

second intervals) the order of the standard DO (bit 0 ... bit 11 from the left).

When [↑], [↓], [→], [←], or [SET] is pressed in the middle of the forced

output, the forced output is ended.

During the forced output, the fastening operation is blocked.

Standard DI monitoring can be performed even during the forced output.

[ZERO/CAL Voltage Error Warning]

If the CAL voltage or ZERO voltage, measured when the control power is

activated, when the self-checking is performed at the start of fastening,

when the CAL switch of the indicator is pressed, or when the RESET signal

is turned “ON,” is of an error warning value, the indication (V Warn) shown

in the drawing below will be indicated. When the RESET signal is turned

“ON” after the warning indication, the [------] is re-indicated.

[Tool Rotation Speed Monitor] (+: CW/-: CCW)

During stoppage: The maximum rotation speed of the connected tool is

indicated.

During rotation: The connected tool rotation speed converted from the motor

feedback speed is indicated.

[Used for in-house adjustment] (0~255)

[Used for in-house adjustment] (0~15)

(Continued on next page)

S0140185-H

Loading...

Loading...