Safety

Information

Introduction

Product

Information

System

configuration

Mechanical

Installation

Electrical

Installation

Getting

Started

Basic

parameters

Running

the motor

Optimization

SMARTCARD

operation

Onboard

PLC

Advanced

parameters

Technical

Data

Diagnostics

UL Listing

Information

Unidrive SPM User Guide 119

Issue Number: 3 www.controltechniques.com

When a keypad is installed, this parameter enables the forward/reverse

key.

This parameter shows the number of the data block last transferred from

a SMARTCARD to the drive.

* Modes 1 and 2 are not user saved, Modes 0, 3 and 4 are user saved.

N

If Pr 0.30 is equal to 1 or 2 this value is not transferred to the EEPROM

or the drive. If Pr 0.30 is set to a 3 or 4 the value is transferred.

For further information, please refer to Chapter 11 SMARTCARD

operation on page 149.

Pr 0.31 indicates the voltage rating of the drive.

Pr 0.32 indicates the maximum continuous Heavy Duty current rating.

Open-loop

When the drive is enabled with Pr 0.33 = 0, the output frequency starts at

zero and ramps to the required reference. When the drive is enabled

when Pr 0.33 has a non-zero value, the drive performs a start-up test to

determine the motor speed and then sets the initial output frequency to

the synchronous frequency of the motor. Restrictions may be placed on

the frequencies detected by the drive as follows:

Closed-loop vector

The motor rated full load rpm parameter (Pr 0.45) in conjunction with the

motor rated frequency parameter (Pr 0.46) defines the full load slip of the

motor. The slip is used in the motor model for closed-loop vector control.

The full load slip of the motor varies with rotor resistance which can vary

significantly with motor temperature. When Pr 0.33 is set to 1 or 2, the

drive can automatically sense if the value of slip defined by Pr 0.45 and

Pr 0.46 has been set incorrectly or has varied with motor temperature. If

the value is incorrect parameter Pr 0.45 is automatically adjusted. The

adjusted value in Pr 0.45 is not saved at power-down. If the new value is

required at the next power-up it must be saved by the user.

Automatic optimisation is only enabled when the speed is above 12.5%

of rated speed, and when the load on the motor load rises above 62.5%

rated load. Optimisation is disabled again if the load falls below 50% of

rated load.

For best optimisation results the correct values of stator resistance (Pr

5.17), transient inductance (Pr 5.24), stator inductance (Pr 5.25) and

saturation breakpoints (Pr 5.29, Pr 5.30) should be stored in the relevant

parameters. These values can be obtained by the drive during an

autotune (see Pr 0.40 for further details).

Rated rpm auto-tune is not available if the drive is not using external

position/speed feedback.

The gain of the optimiser, and hence the speed with which it converges,

can be set at a normal low level when Pr 0.33 is set to 1. If this

parameter is set to 2 the gain is increased by a factor of 16 to give faster

convergence.

If any number other than 0 is programmed into this parameter, user

security is applied so that no parameters except parameter 0.49 can be

adjusted with the keypad. When this parameter is read via a keypad it

appears as zero.

For further details refer to section 7.9.3 User Security on page 106.

This parameter defines the communications protocol used by the

EIA485 comms port on the drive. This parameter can be changed via the

drive keypad, via a Solutions Module or via the comms interface itself. If

it is changed via the comms interface, the response to the command

uses the original protocol. The master should wait at least 20ms before

send a new message using the new protocol. (Note: ANSI uses 7 data

bits, 1 stop bit and even parity; Modbus RTU uses 8 data bits, 2 stops

bits and no parity.)

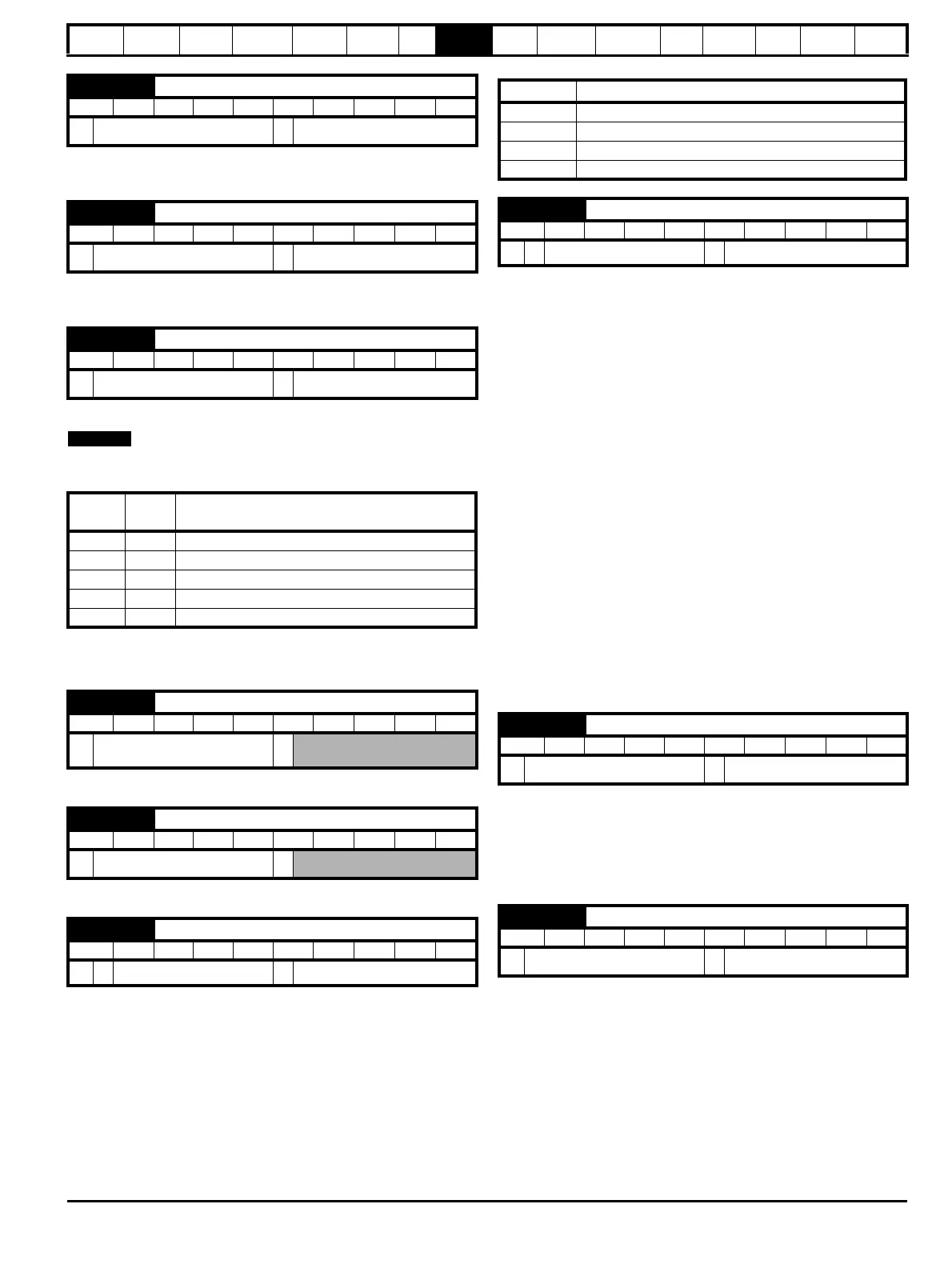

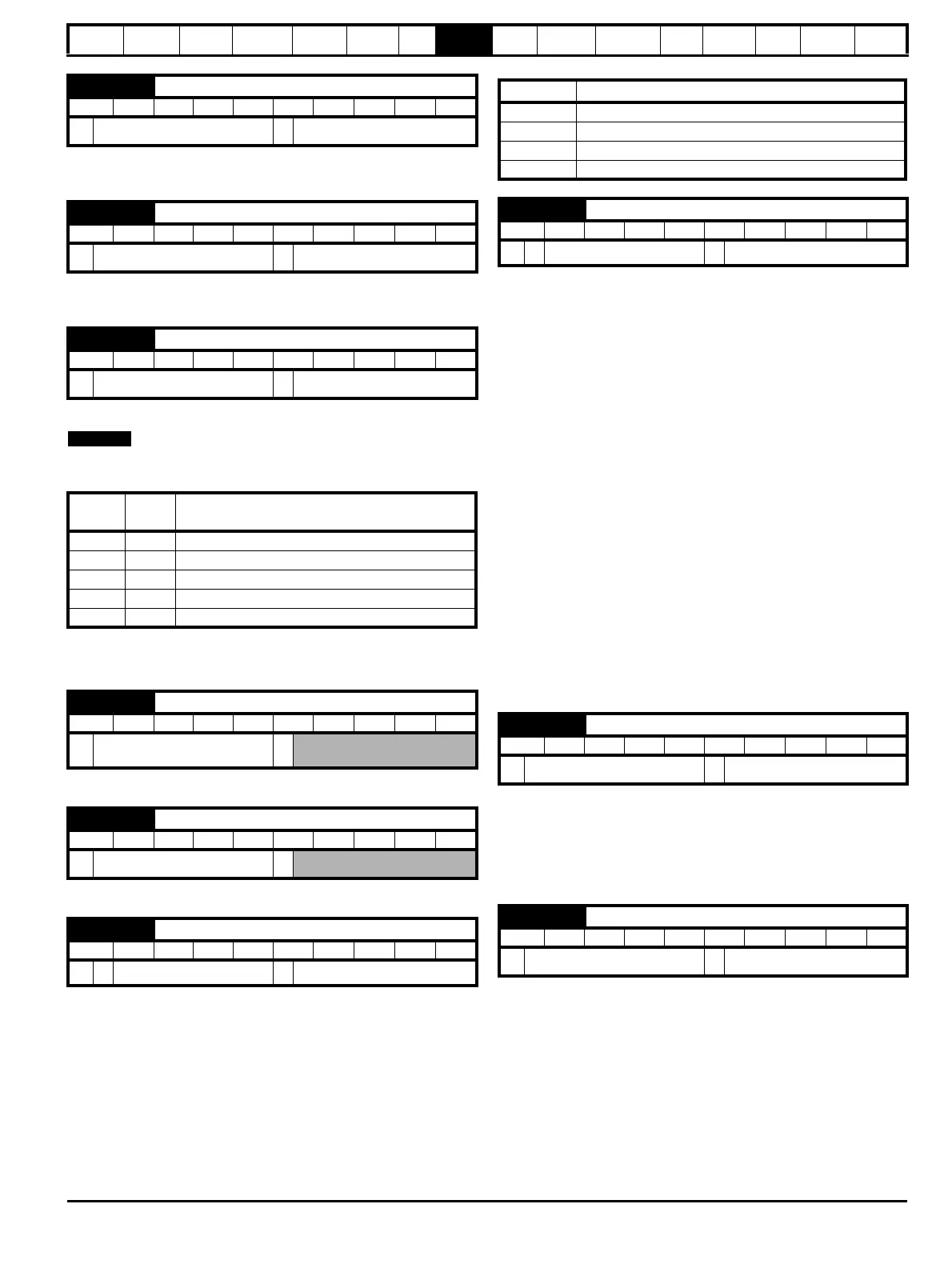

0.28 {6.13} Keypad fwd/rev key enable

RW Bit US

Ú

OFF (0) or On (1)

Ö

OFF (0)

0.29 {11.36} SMARTCARD parameter data

RO Uni NC PT US

Ú

0 to 999

Ö

0

0.30 {11.42} Parameter copying

RW Txt NC *

Ú

0 to 4

Ö

nonE (0)

Pr

String

Pr

value

Comment

nonE 0 Inactive

rEAd 1 Read parameter set from the SMARTCARD

Prog 2 Programming a parameter set to the SMARTCARD

Auto 3 Auto save

boot 4 Boot mode

0.31 {11.33} Drive rated voltage

RO Txt NC PT

Ú

200V (0), 400V (1), 575V (2),

690V (3)

Ö

0.32 {11.32} Maximum Heavy Duty current rating

RO Uni NC PT

Ú

0.00 to 9,999.99 A

Ö

0.33 {6.09} Catch a spinning motor

RW Uni US

OL

Ú

0 to 3

Ö

0

Pr 0.33 Function

0 Disabled

1 Detect all frequencies

2 Detect positive frequencies only

3 Detect negative frequencies only

0.33 {5.16} Rated rpm autotune

RW Uni US

VT

Ú

0 to 2

Ö

0

0.34 {11.30} User security code

RW Uni NC PT PS

Ú

0 to 999

Ö

0

0.35 {11.24} Serial comms mode

RW Txt US

Ú

AnSI (0), rtu (1), Lcd (2)

Ö

rtU (1)

Loading...

Loading...