Safety

Information

Introduction

Product

Information

System

configuration

Mechanical

Installation

Electrical

Installation

Getting

Started

Basic

parameters

Running

the motor

Optimization

SMARTCARD

operation

Onboard

PLC

Advanced

parameters

Technical

Data

Diagnostics

UL Listing

Information

120 Unidrive SPM User Guide

www.controltechniques.com Issue Number: 3

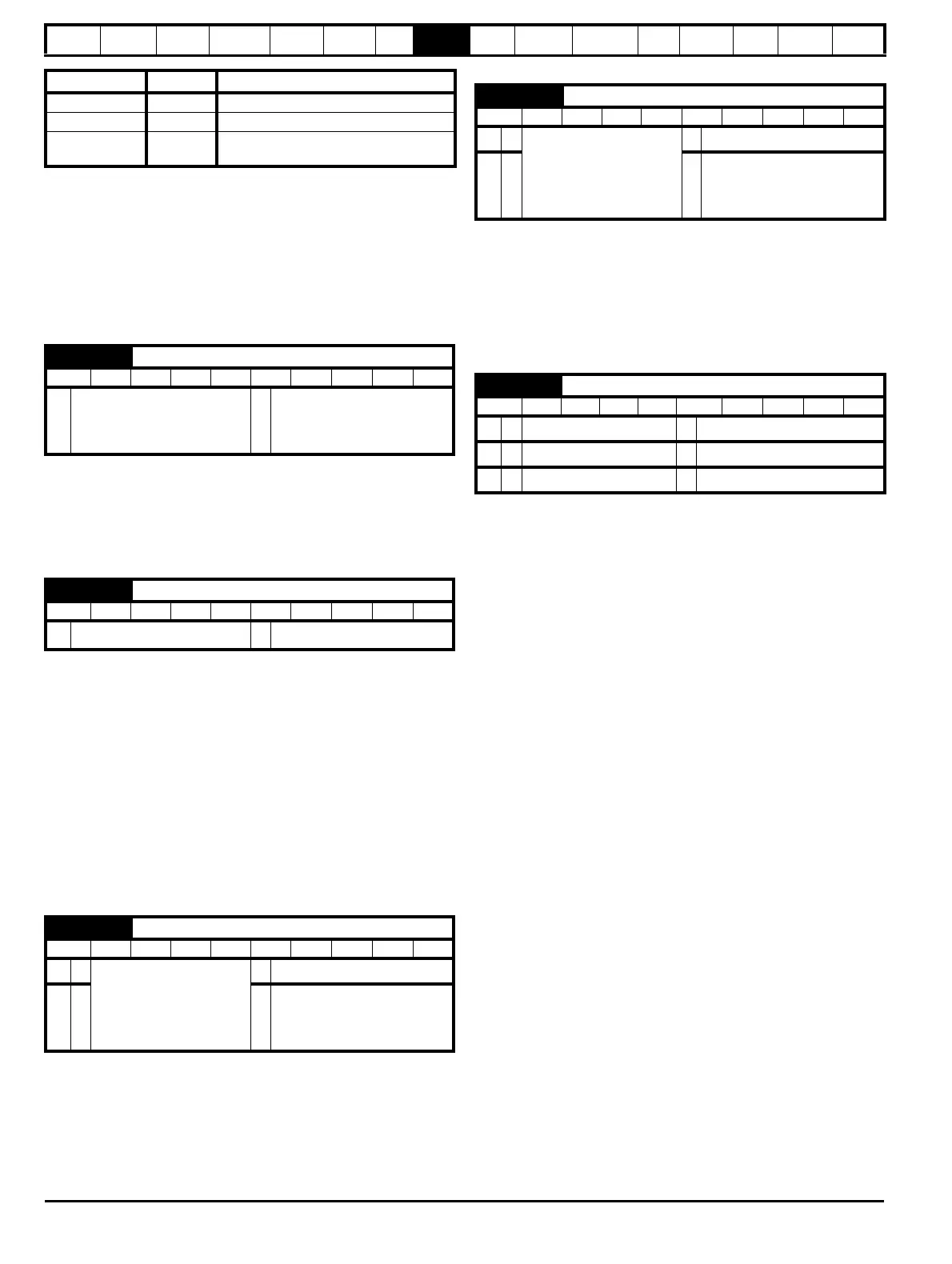

ANSIx3.28 protocol

Full details of the CT ANSI communications protocol are the Advanced

User Guide.

Modbus RTU protocol

Full details of the CT implementation of Modbus RTU are given in the

Advanced User Guide.

Modbus RTU protocol, but with an SM-Keypad only

This setting is used for disabling communications access when the SM-

Keypad is used as a hardware key.

* only applicable to Modbus RTU mode

This parameter can be changed via the drive keypad, via a Solutions

Module or via the comms interface itself. If it is changed via the comms

interface, the response to the command uses the original baud rate. The

master should wait at least 20ms before send a new message using the

new baud rate.

Used to define the unique address for the drive for the serial interface.

The drive is always a slave.

Modbus RTU

When the Modbus RTU protocol is used addresses between 0 and 247

are permitted. Address 0 is used to globally address all slaves, and so

this address should not be set in this parameter

ANSI

When the ANSI protocol is used the first digit is the group and the

second digit is the address within a group. The maximum permitted

group number is 9 and the maximum permitted address within a group is

9. Therefore, Pr 0.37 is limited to 99 in this mode. The value 00 is used

to globally address all slaves on the system, and x0 is used to address

all slaves of group x, therefore these addresses should not be set in this

parameter.

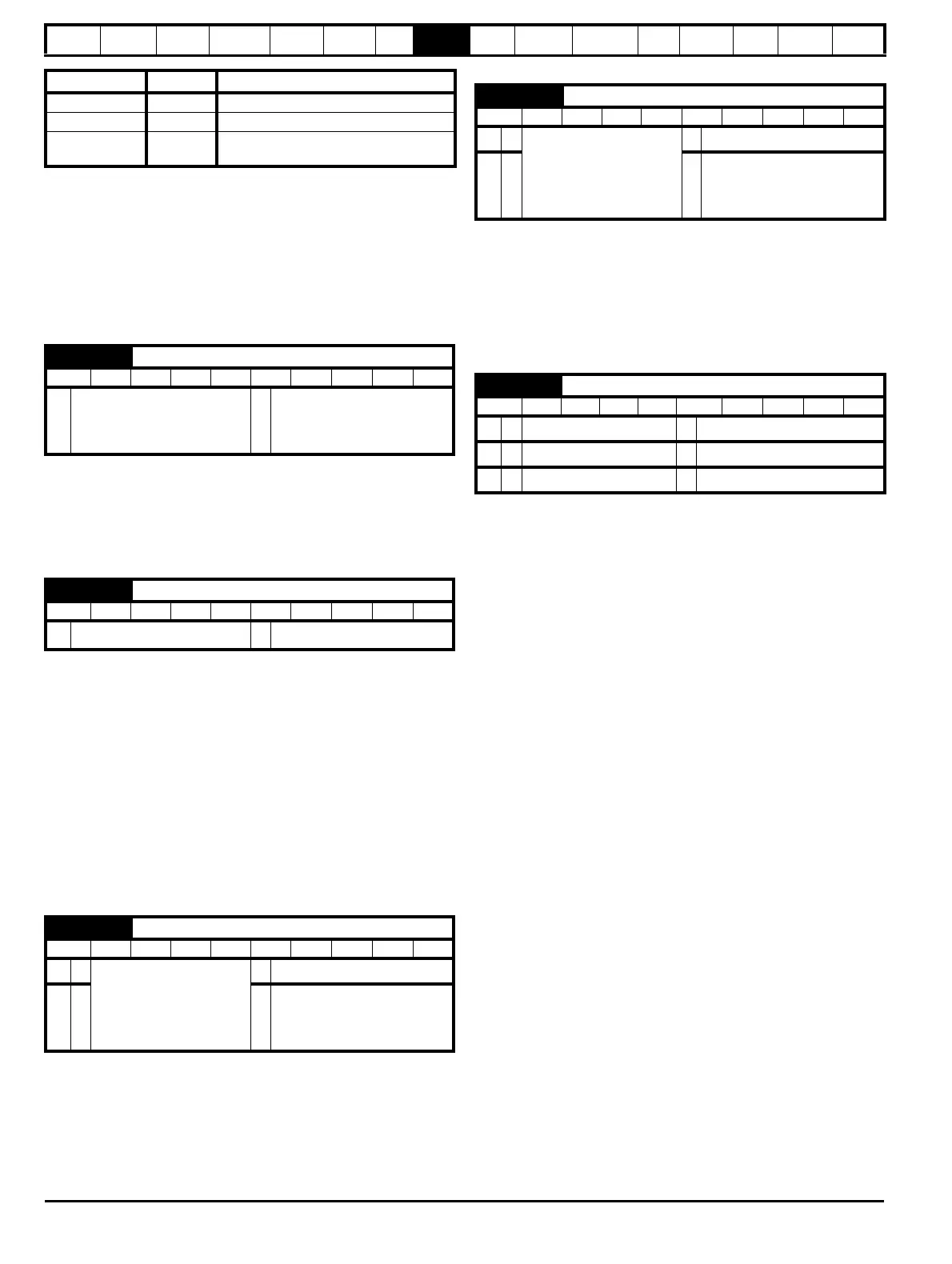

These parameters control the proportional and integral gains of the

current controller used in the open loop drive. The current controller

either provides current limits or closed loop torque control by modifying

the drive output frequency. The control loop is also used in its torque

mode during line power supply loss, or when the controlled mode

standard ramp is active and the drive is decelerating, to regulate the flow

of current into the drive.

Open-Loop

There are two autotune tests available in open loop mode, a stationary

and a rotating test. A rotating autotune should be used whenever

possible, so the measured value of power factor of the motor is used by

the drive.

• The stationary autotune can be used when the motor is loaded and it

is not possible to remove the load from the motor shaft.

• A rotating autotune first performs a stationary autotune, before

rotating the motor at

2

/

3

base speed in the forward direction for

several seconds. The motor must be free from load for the rotating

autotune.

To perform an autotune, set Pr 0.40 to 1 for a stationary test or 2 for a

rotating test, and provide the drive with both an enable signal (on

terminal 31) and a run signal (on terminal 26 or 27).

Following the completion of an autotune test the drive will go into the

inhibit state. The drive must be placed into a controlled disable condition

before the drive can be made to run at the required reference. The drive

can be put in to a controlled disable condition by removing the SAFE

TORQUE OFF (SECURE DISABLE) signal from terminal 31, setting the

drive enable parameter Pr 6.15 to OFF (0) or disabling the drive via the

control word (Pr 6.42 & Pr 6.43).

For further information refer to section Pr 0.40 {5.12} Autotune on

page 136.

Closed-loop

There are three autotune tests available in closed loop vector mode, a

stationary test, a rotating test and an inertia measurement test. A

stationary autotune will give moderate performance whereas a rotating

autotune will give improved performance as it measures the actual

values of the motor parameters required by the drive. An inertia

measurement test should be performed separately to a stationary or

rotating autotune.

• The stationary autotune can be used when the motor is loaded and it

is not possible to remove the load from the motor shaft.

• A rotating autotune first performs a stationary autotune, before

rotating the motor at

2

/

3

base speed in the forward direction for

approximately 30 seconds. The motor must be free from load for the

rotating autotune.

• The inertia measurement test can measure the total inertia of the

load and the motor. This is used to set the speed loop gains (see

Comms value String Communications mode

0 AnSI ANSI

1 rtU Modbus RTU protocol

2Lcd

Modbus RTU protocol, but with an SM-

Keypad only

0.36 {11.25} Serial comms baud rate

RW Txt US

Ú

300 (0), 600 (1), 1200 (2),

2400 (3), 4800 (4), 9600 (5),

19200 (6), 38400 (7),

57600 (8)*, 115200 (9)*

Ö

19200 (6)

0.37 {11.23} Serial comms address

RW Uni US

Ú

0 to 247

Ö

1

0.38 {4.13} Current loop P gain

RW Uni US

OL

Ú

0 to 30,000

Ö

All voltage ratings: 20

CL

ÚÖ

200V drive: 75

400V drive: 150

575V drive: 180

690V drive: 215

0.39 {4.14} Current loop I gain

RW Uni US

OL

Ú

0 to 30,000

Ö

All voltage ratings: 40

CL

ÚÖ

200V drive: 1,000

400V drive: 2,000

575V drive: 2,400

690V drive: 3,000

0.40 {5.12} Autotune

RW Uni

OL

Ú

0 to 2

Ö

0

VT

Ú

0 to 4

Ö

0

SV

Ú

0 to 6

Ö

0

Loading...

Loading...