Safety

Information

Introduction

Product

Information

System

configuration

Mechanical

Installation

Electrical

Installation

Getting

Started

Basic

parameters

Running

the motor

Optimization

SMARTCARD

operation

Onboard

PLC

Advanced

parameters

Technical

Data

Diagnostics

UL Listing

Information

Unidrive SPM User Guide 121

Issue Number: 3 www.controltechniques.com

Speed loop gains, below) and to provide torque feed forwards when

required during acceleration. During the inertia measurement test

the motor speed changes from

1

/

3

to

2

/

3

rated speed in the forward

direction several times. The motor can be loaded with a constant

torque load and still give an accurate result, however, non-linear

loads and loads that change with speed will cause measurement

errors.

To perform an autotune, set Pr 0.40 to 1 for a stationary test, 2 for a

rotating test, or 3 for an inertia measurement test and provide the drive

with both an enable signal (on terminal 31) and a run signal (on terminal

26 or 27).

Following the completion of an autotune test the drive will go into the

inhibit state. The drive must be placed into a controlled disable condition

before the drive can be made to run at the required reference. The drive

can be put in to a controlled disable condition by removing the SAFE

TORQUE OFF (SECURE DISABLE) signal from terminal 31, setting the

drive enable parameter Pr 6.15 to OFF (0) or disabling the drive via the

control word (Pr 6.42 & Pr 6.43).

Setting Pr 0.40 to 4 will cause the drive to calculate the current loop

gains based on the previously measured values of motor resistance and

inductance. The drive does apply any voltage to the motor during this

test. The drive will change Pr 0.40 back to 0 as soon as the calculations

are complete (approximately 500ms).

For further information refer to section Pr 0.40 {5.12} Autotune on

page 139.

Servo

There are five autotune tests available in servo mode, a short low speed

test, a normal low speed test, an inertia measurement test, a stationary

test and a minimal movement test. A normal low speed should be done

where possible as the drive measures the stator resistance and

inductance of the motor, and from these calculates the current loop

gains. An inertia measurement test should be performed separately to a

short low speed or normal low speed autotune.

• A short low speed test will rotate the motor by 2 electrical revolutions

(i.e. up to 2 mechanical revolutions) in the forward direction, and

measure the encoder phase angle. The motor must be free from

load for this test.

• A normal low speed test will rotate the motor by 2 electrical

revolutions (i.e. up to 2 mechanical revolutions) in the forward

direction. This test measures the encoder phase angle and updates

other parameters including the current loop gains. The motor must

be free from load for this test.

• The inertia measurement test can measure the total inertia of the

load and the motor. This is used to set the speed loop gains and to

provide torque feed forwards when required during acceleration.

During the inertia measurement test the motor speed changes from

1

/

3

to

2

/

3

rated speed in the forward direction several times. The

motor can be loaded with a constant torque load and still give an

accurate result, however, non-linear loads and loads that change

with speed will cause measurement errors.

• The stationary test only measures the motor resistance and

inductance, and updates the current loop gain parameters. This test

does not measure the encoder phase angle so this test needs to be

done in conjunction with either the short low speed or minimal

movement tests.

• The minimal movement test will move the motor through a small

angle to measure the encoder phase angle. This test will operate

correctly when the load is an inertia, and although a small amount of

cogging and stiction is acceptable, this test cannot be used for a

loaded motor.

To perform an autotune, set Pr 0.40 to 1 for a short low speed test, 2 for

a normal low speed test, 3 for an inertia measurement test, 4 for a

stationary test or 5 for a minimal movement test, and provide the drive

with both an enable signal (on terminal 31) and a run signal (on terminal

26 or 27).

Following the completion of an autotune test the drive will go into the

inhibit state. The drive must be placed into a controlled disable condition

before the drive can be made to run at the required reference. The drive

can be put in to a controlled disable condition by removing the SAFE

TORQUE OFF (SECURE DISABLE) signal from terminal 31, setting the

drive enable parameter Pr 6.15 to OFF (0) or disabling the drive via the

control word (Pr 6.42 & Pr 6.43).

Setting Pr 0.40 to 6 will cause the drive to calculate the current loop

gains based on the previously measured values of motor resistance and

inductance. The drive does apply any voltage to the motor during this

test. The drive will change Pr 0.40 back to 0 as soon as the calculations

are complete (approximately 500ms).

For further information refer to section Pr 0.40 {5.12} Autotune on

page 139.

This parameter defines the required switching frequency. The drive may

automatically reduce the actual switching frequency (without changing

this parameter) if the power stage becomes too hot. A thermal model of

the IGBT junction temperature is used based on the heatsink

temperature and an instantaneous temperature drop using the drive

output current and switching frequency. The estimated IGBT junction

temperature is displayed in Pr 7.34. If the temperature exceeds 145°C

the switching frequency is reduced if this is possible (i.e >3kHz).

Reducing the switching frequency reduces the drive losses and the

junction temperature displayed in Pr 7.34 also reduces. If the load

condition persists the junction temperature may continue to rise again

above 145°C and the drive cannot reduce the switching frequency

further the drive will initiate an ‘O.ht1’ trip. Every second the drive will

attempt to restore the switching frequency to the level set in Pr 0.41.

The full range of switching frequencies is not available on all ratings of

Unidrive SP. See section 10.5 Switching frequency on page 147, for the

maximum available switching frequency for each drive rating.

8.2.7 Motor parameters

Open-loop

This parameter is used in the calculation of motor speed, and in applying

the correct slip compensation. When auto is selected, the number of

motor poles is automatically calculated from the rated frequency (Pr

0.47) and the rated full load rpm (Pr 0.45). The number of poles = 120 *

rated frequency / rpm rounded to the nearest even number.

Closed-loop vector

This parameter must be set correctly for the vector control algorithms to

operate correctly. When auto is selected, the number of motor poles is

automatically calculated from the rated frequency (Pr 0.47) and the rated

full load rpm (Pr 0.45). The number of poles = 120 * rated frequency /

rpm rounded to the nearest even number.

Servo

This parameter must be set correctly for the vector control algorithms to

operate correctly. When auto is selected the number of poles is set to 6.

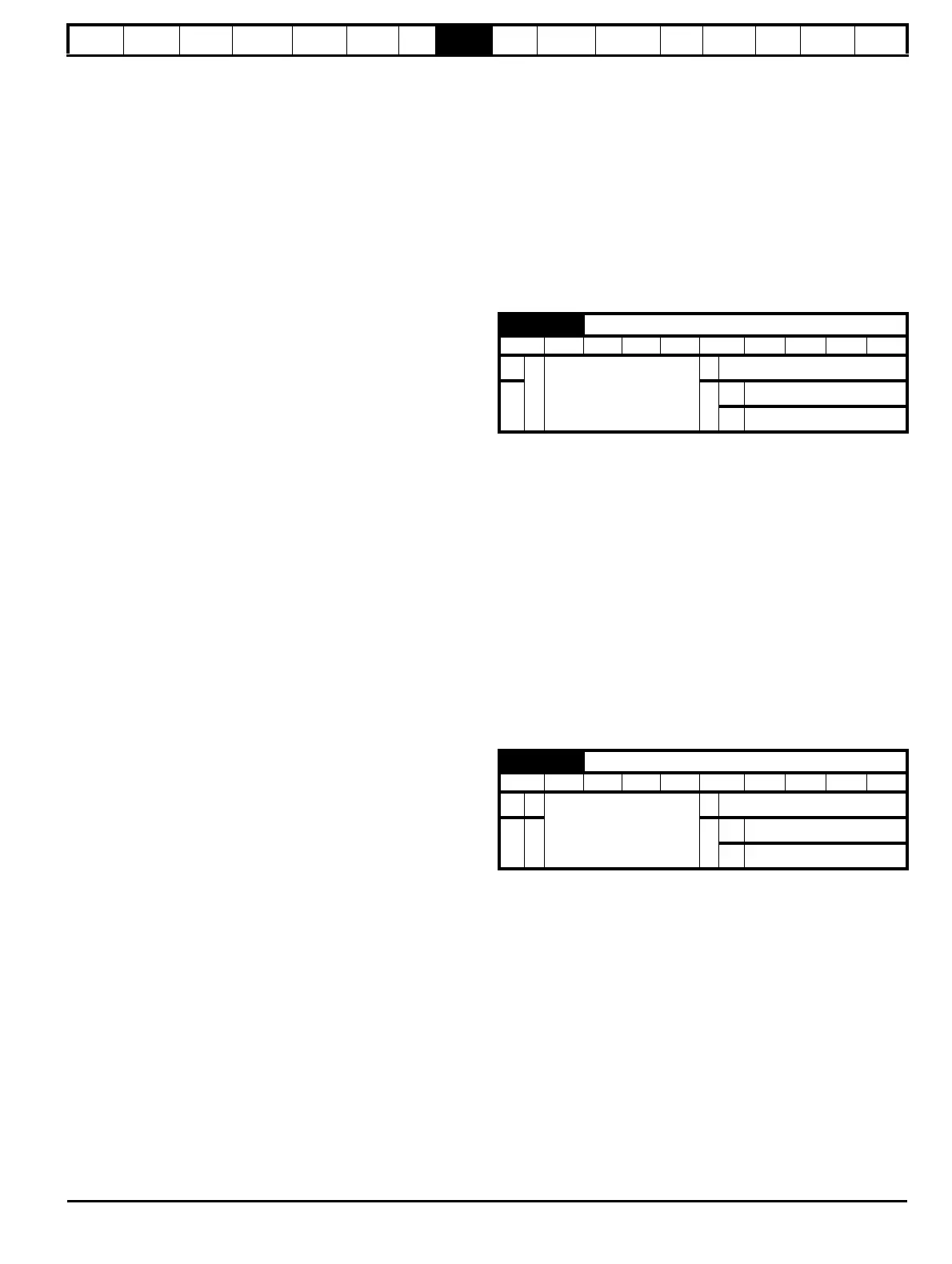

0.41 {5.18} Maximum switching frequency

RW Txt RA US

OL

Ú

3 (0), 4 (1), 6 (2)

Ö

3 (0)

CL

Ö

VT 3 (0)

SV 6 (2)

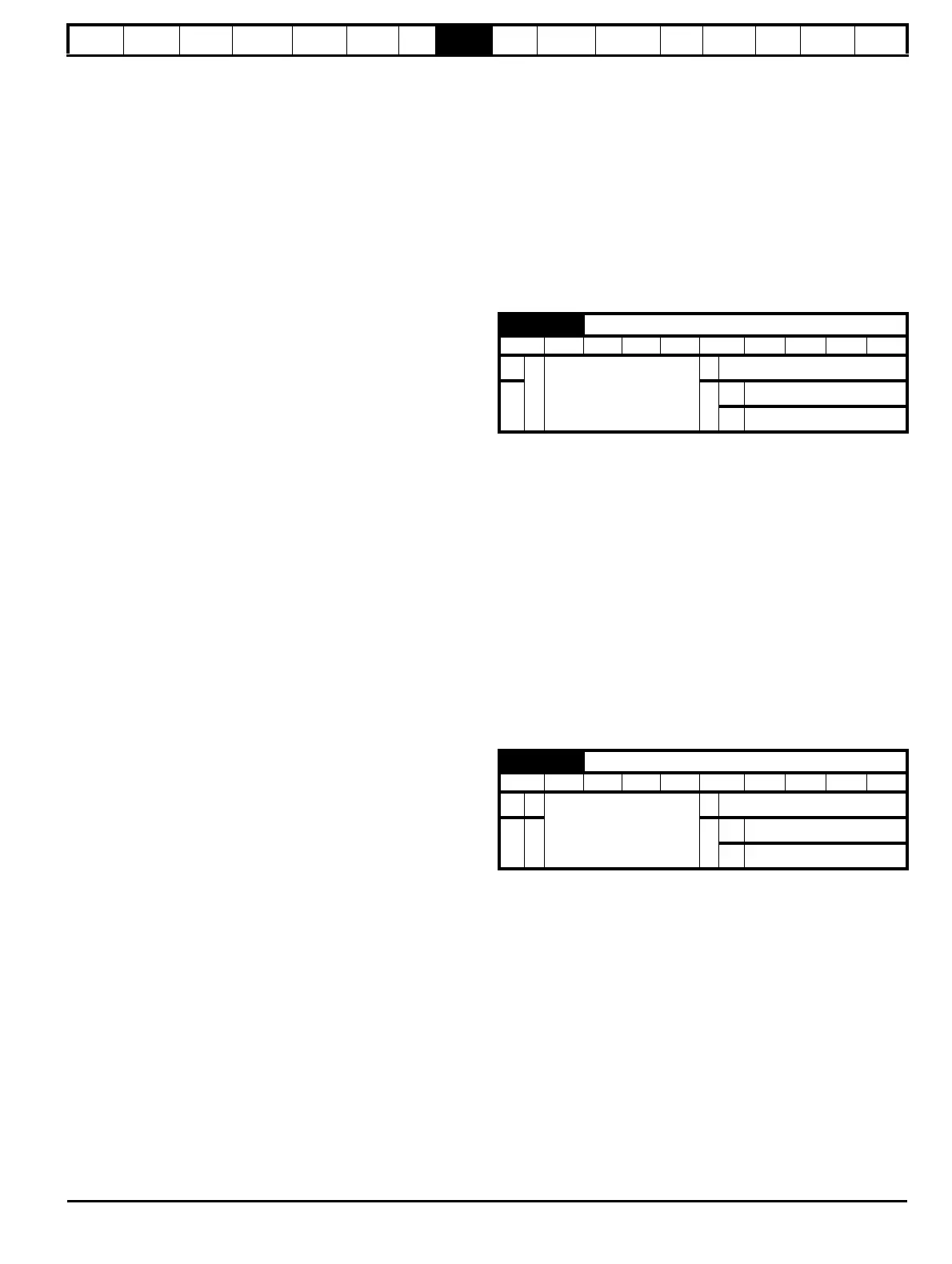

0.42 {5.11} No. of motor poles

RW Txt US

OL

Ú

0 to 60 (Auto to 120 Pole)

Ö

Auto (0)

CL

ÚÖ

VT Auto (0)

SV 6 POLE (3)

Loading...

Loading...