Safety

Information

Introduction

Product

Information

System

configuration

Mechanical

Installation

Electrical

Installation

Getting

Started

Basic

parameters

Running

the motor

Optimization

SMARTCARD

operation

Onboard

PLC

Advanced

parameters

Technical

Data

Diagnostics

UL Listing

Information

122 Unidrive SPM User Guide

www.controltechniques.com Issue Number: 3

The power factor is the true power factor of the motor, i.e. the angle

between the motor voltage and current.

Open-loop

The power factor is used in conjunction with the motor rated current

(Pr 0.46) to calculate the rated active current and magnetising current of

the motor. The rated active current is used extensively to control the

drive, and the magnetising current is used in vector mode Rs

compensation. It is important that this parameter is set up correctly.

This parameter is obtained by the drive during a rotational autotune. If a

stationary autotune is carried out, then the nameplate value should be

entered in Pr 0.43.

Closed-loop vector

If the stator inductance (Pr 5.25) contains a non-zero value, the power

factor used by the drive is continuously calculated and used in the vector

control algorithms (this will not update Pr 0.43).

If the stator inductance is set to zero (Pr 5.25) then the power factor

written in Pr 0.43 is used in conjunction with the motor rated current and

other motor parameters to calculate the rated active and magnetising

currents which are used in the vector control algorithm.

This parameter is obtained by the drive during a rotational autotune. If a

stationary autotune is carried out, then the nameplate value should be

entered in Pr 0.43.

The phase angle between the rotor flux in a servo motor and the

encoder position is required for the motor to operate correctly. If the

phase angle is known it can be set in this parameter by the user.

Alternatively the drive can automatically measure the phase angle by

performing a phasing test (see autotune in servo mode Pr 0.40). When

the test is complete the new value is written to this parameter. The

encoder phase angle can be modified at any time and becomes effective

immediately. This parameter has a factory default value of 0.0, but is not

affected when defaults are loaded by the user.

Open-loop & Closed-loop vector

Enter the value from the rating plate of the motor.

Open-loop

This is the speed at which the motor would rotate when supplied with its

base frequency at rated voltage, under rated load conditions (=

synchronous speed - slip speed). Entering the correct value into this

parameter allows the drive to increase the output frequency as a

function of load in order to compensate for this speed drop.

Slip compensation is disabled if Pr 0.45 is set to 0 or to synchronous

speed, or if Pr 5.27 is set to 0.

If slip compensation is required this parameter should be set to the value

from the rating plate of the motor, which should give the correct rpm for a

hot machine. Sometimes it will be necessary to adjust this when the

drive is commissioned because the nameplate value may be inaccurate.

Slip compensation will operate correctly both below base speed and

within the field weakening region. Slip compensation is normally used to

correct for the motor speed to prevent speed variation with load. The

rated load rpm can be set higher than synchronous speed to deliberately

introduce speed droop. This can be useful to aid load sharing with

mechanically coupled motors.

Closed loop vector

Rated load rpm is used with motor rated frequency to determine the full

load slip of the motor which is used by the vector control algorithm.

Incorrect setting of this parameter can result in the following:

• Reduced efficiency of motor operation

• Reduction of maximum torque available from the motor

• Failure to reach maximum speed

• Over-current trips

• Reduced transient performance

• Inaccurate control of absolute torque in torque control modes

The nameplate value is normally the value for a hot machine, however,

some adjustment may be required when the drive is commissioned if the

nameplate value is inaccurate.

The rated full load rpm can be optimised by the drive (For further

information, refer to section 10.1.3 Closed loop vector motor control on

page 141).

Servo

Pr 0.45 is the motor thermal time constant of the motor, and is used

(along with the motor rated current Pr 0.46, and total motor current

Pr 0.12) in the thermal model of the motor in applying thermal protection

to the motor.

Setting this parameter to 0 disables the motor thermal protection.

For further details, refer to section 10.4 Motor thermal protection on

page 146.

Enter the name-plate value for the motor rated current.

Open-loop & Closed-loop vector

Enter the value from the rating plate of the motor.

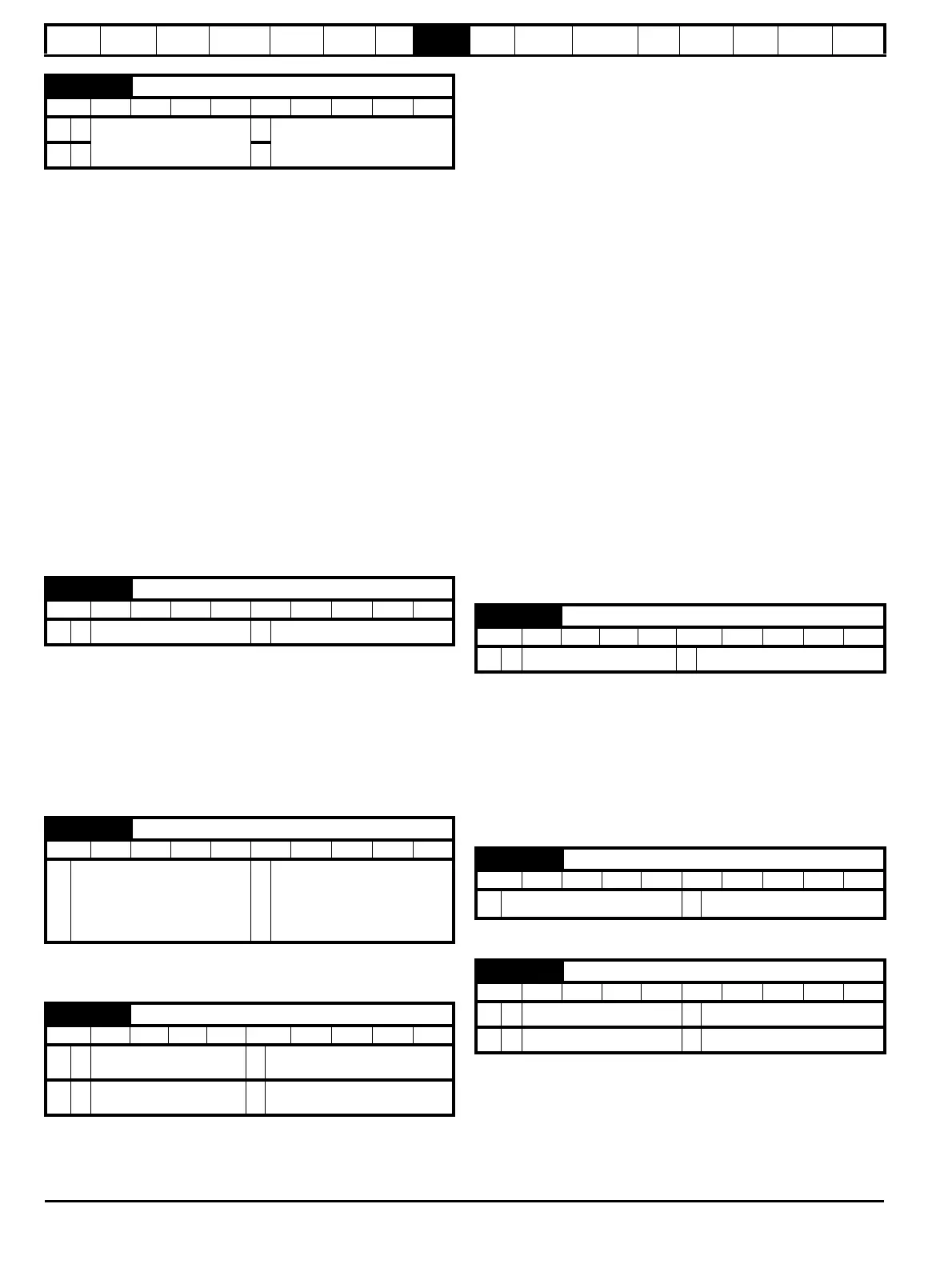

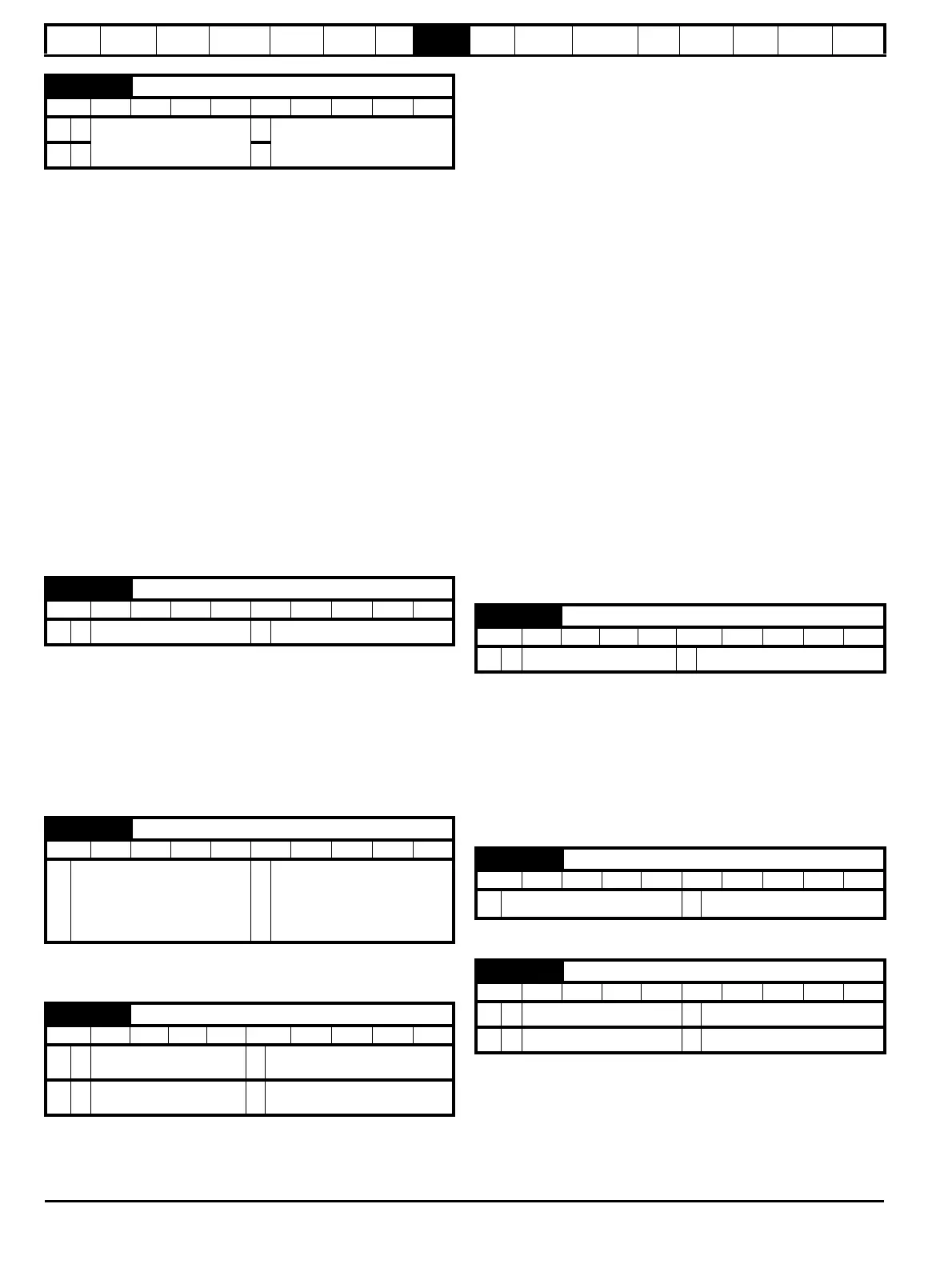

0.43 {5.10} Motor rated power factor

RW Uni US

OL

Ú

0.000 to 1.000

Ö

0.850

VT

ÚÖ

0.43 {3.25} Encoder phase angle

RW Uni US

SV

Ú

0.0 to 359.9°

Ö

0.0

0.44 {5.09} Motor rated voltage

RW Uni RA US

Ú

0 to

AC_VOLTAGE_SET_MAX V

Ö

200V drive: 230

400V drive: EUR> 400

USA> 460

575V drive: 575

690V drive: 690

0.45 {5.08} Motor rated full load speed (rpm)

RW Uni US

OL

Ú

0 to 180,000 rpm

Ö

EUR> 1,500

USA> 1,800

VT

Ú

0.00 to 40,000.00 rpm

Ö

EUR> 1,450.00

USA> 1,770.00

0.45 {4.15} Motor thermal time constant

RW Uni US

SV

Ú

0 to 3000.0

Ö

20.0

0.46 {5.07} Motor rated current

RW Uni RA US

Ú

0 to Rated_current_max A

Ö

Drive rated current [11.32]

0.47 {5.06} Rated frequency

RW Uni US

OL

Ú

0 to 3,000.0Hz

Ö

EUR> 50.0, USA> 60.0

VT

Ú

0 to 1,250.0Hz

Ö

EUR> 50.0, USA> 60.0

Loading...

Loading...