Maintenance 6. Arm #2

G10 / G20 Rev.20 153

A new reduction gear unit contains the

shown in the picture on the right

the circular spline and the tap

grease (SK-1A) on the gear side of the

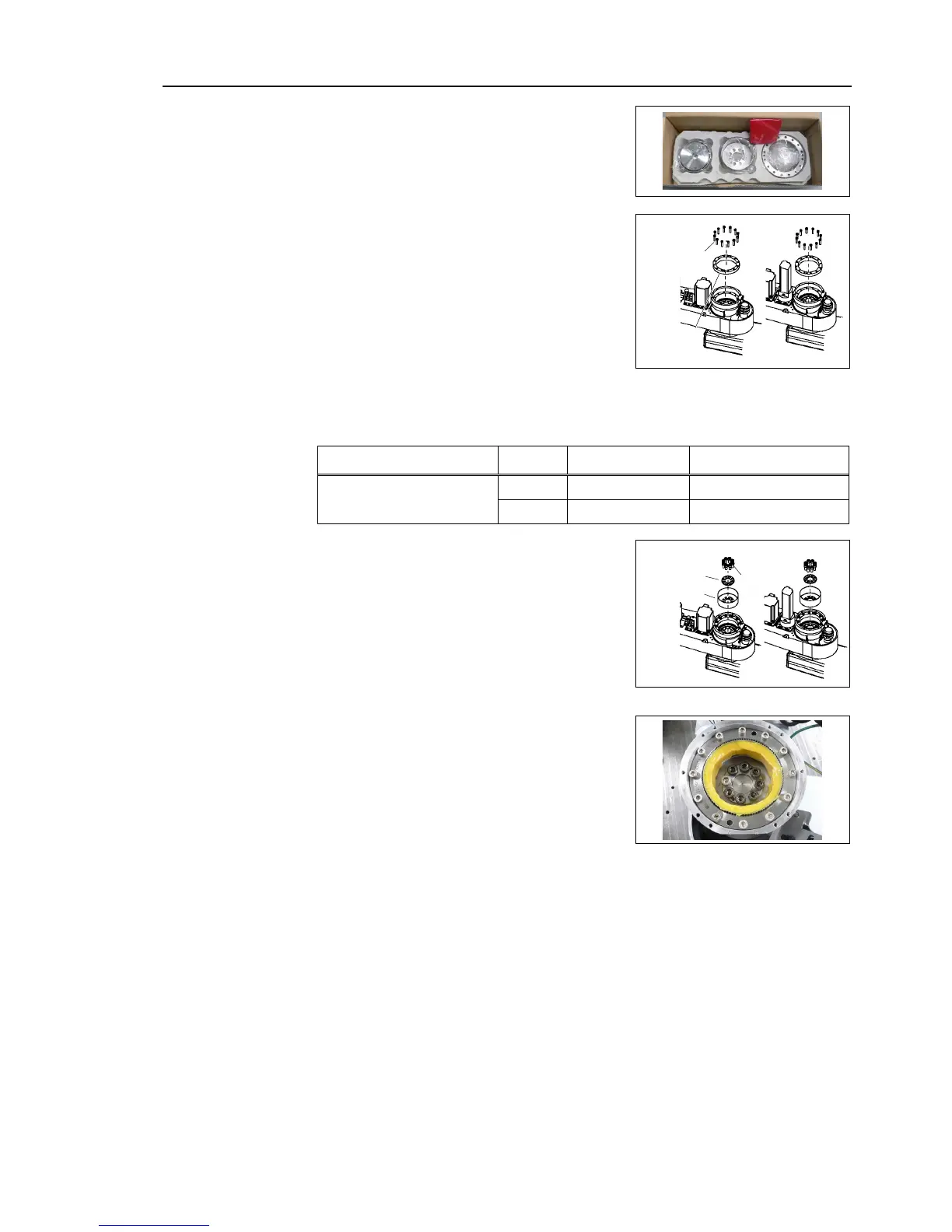

secure all bolts in a crisscross pattern so

that the bolts will be secured

tighten each bolt securely in a

pattern at the torque specified in the

Item Bolt type Number of bolts Tightening torque

Joint #2 reduction gear unit

M5×25

16

10.0 N⋅m (102 kgf⋅cm)

M8×20

8

30.0 N⋅m (306 kgf⋅cm)

-1A) on the flexspline teeth.

flexspline by aligning it with the tap hole.

Aligning the tap hole and mount the flexspline.

the air vent of the spacer.

align the position, move Arm

-1A) inside the flexspline.

Grease volume 43 g

Apply grease to the bearing part of the waveform generator.

Execute steps from (2) to (9) in

Maintenance: 6.1 Replacing Joint #2 Motor.

Loading...

Loading...