T3-B T6-B Manipulator 5. Motion Range

82 T-B series Rev.1

6)

perate the joint changed at low speeds until it reaches the positions of the

maximum pulse range.

Make sure that the arm does not hit the mechanical stops.

(Check the

position of the mechanical stop and the motion range you set.)

The angle of Joint #1 is set from -110° to +110°.

The angle of Joint #2 is set from -120° to +120°.

Execute the following command

s from the [Command Window].

>MOTOR ON ' Turns ON the motor

>POWER LOW ' Enters low-power mode

>SPEED 5 ' Sets at low speeds

>PULSE -45512,0,0,0 ' Moves to the min. pulse position of Joint #1

>PULSE 455112,0,0,0 ' Moves to the max. pulse position of Joint #1

>PULSE 204800,-273066,0,0 ' Moves to the min. pulse position of Joint #2

>PULSE 204800,273066,0,0 ' Moves to the max. pulse position of Joint #2

The Pulse command (Go Pulse command) moves

all joints to the specified positions

Specify safe positions after considering motion of not only the joints

whose pulse range have been changed, but also other joints

.

In this example, Joint #1 is moved to the

center of its motion range

(pulse value:

204800) when checking Joint #2.

is hitting the mechanical stop

s or if an error occurs after the arm hits the

mechanical stops

, either

reset the pulse range to a narrower setting or extend the

positions of the mechanical stops within the limit.

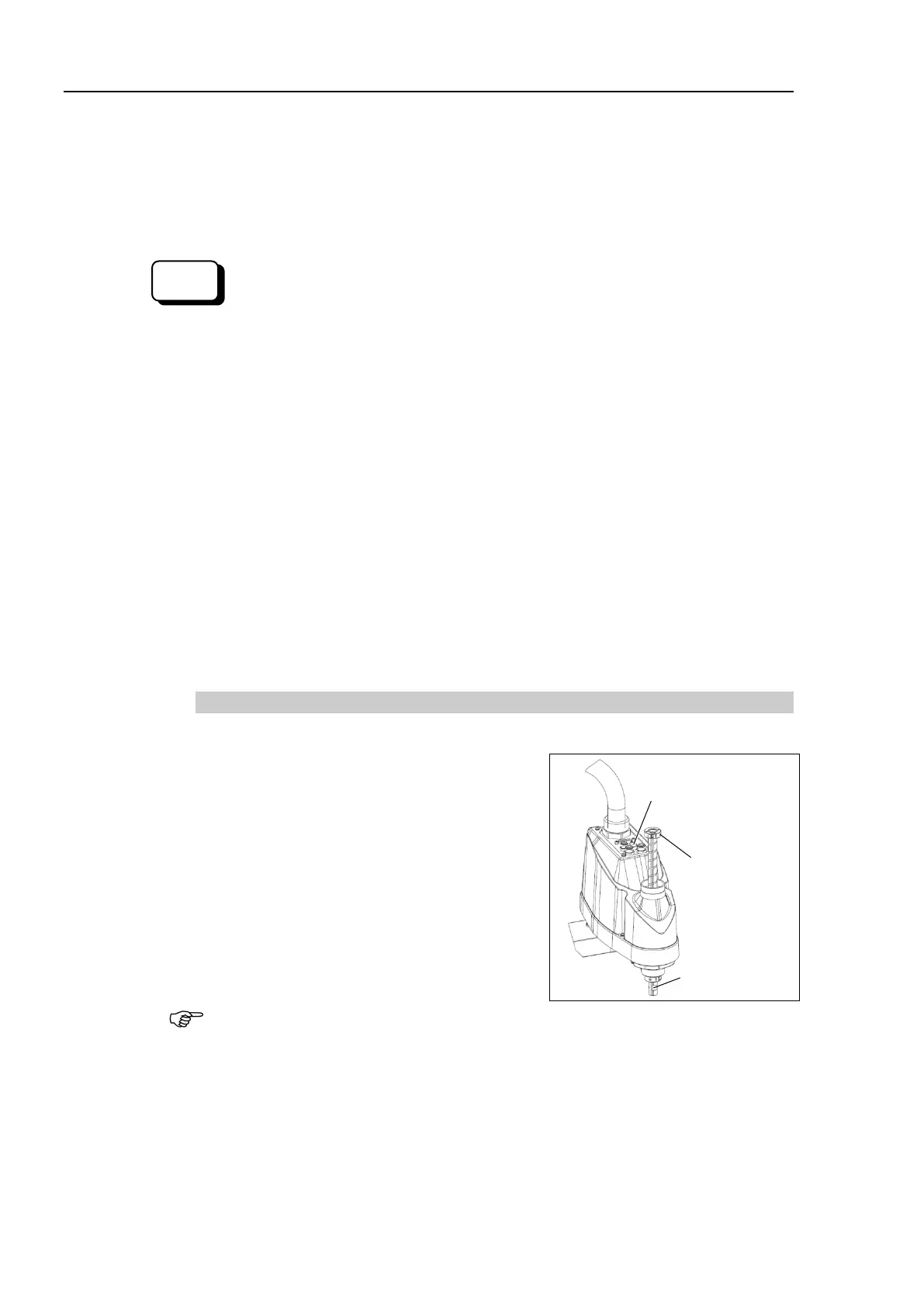

5.2.2 Setting the Mechanical Stop of Joint #3

1)

Turn ON the Manipulator and turn OFF the motors using the Motor OFF command.

2)

Push up the shaft while pressing the brake

release switch.

shaft up to its upper limit or it

will be difficult for the arm top cover to be

removed.

Push the shaft up to a position where

the Joint #3 mechanical stop can be changed.

Lower limit

mechanical

stop screw

T3-B:

M3×10

T6-B:M4×15

the brake release switch, the shaft may lower due to

the weight of the

end effector.

Be sure to hold the shaft by hand while pressing the button.

3)

Manipulator.

Loosen the lower limit mechanical stop screw

(T3-B: M3×10, T6-B: M4×15).

Loading...

Loading...