TORCH DATA 100i-400i 168 Manual 0560956430

Stainless Steel

Flow Rates (SLPM / SCFH)

200A Bevel Cut

H35 N₂

Preow

- / - 73 / 154

H35 Plasma / N₂ Shield

Culow

35 / 74 49 / 103

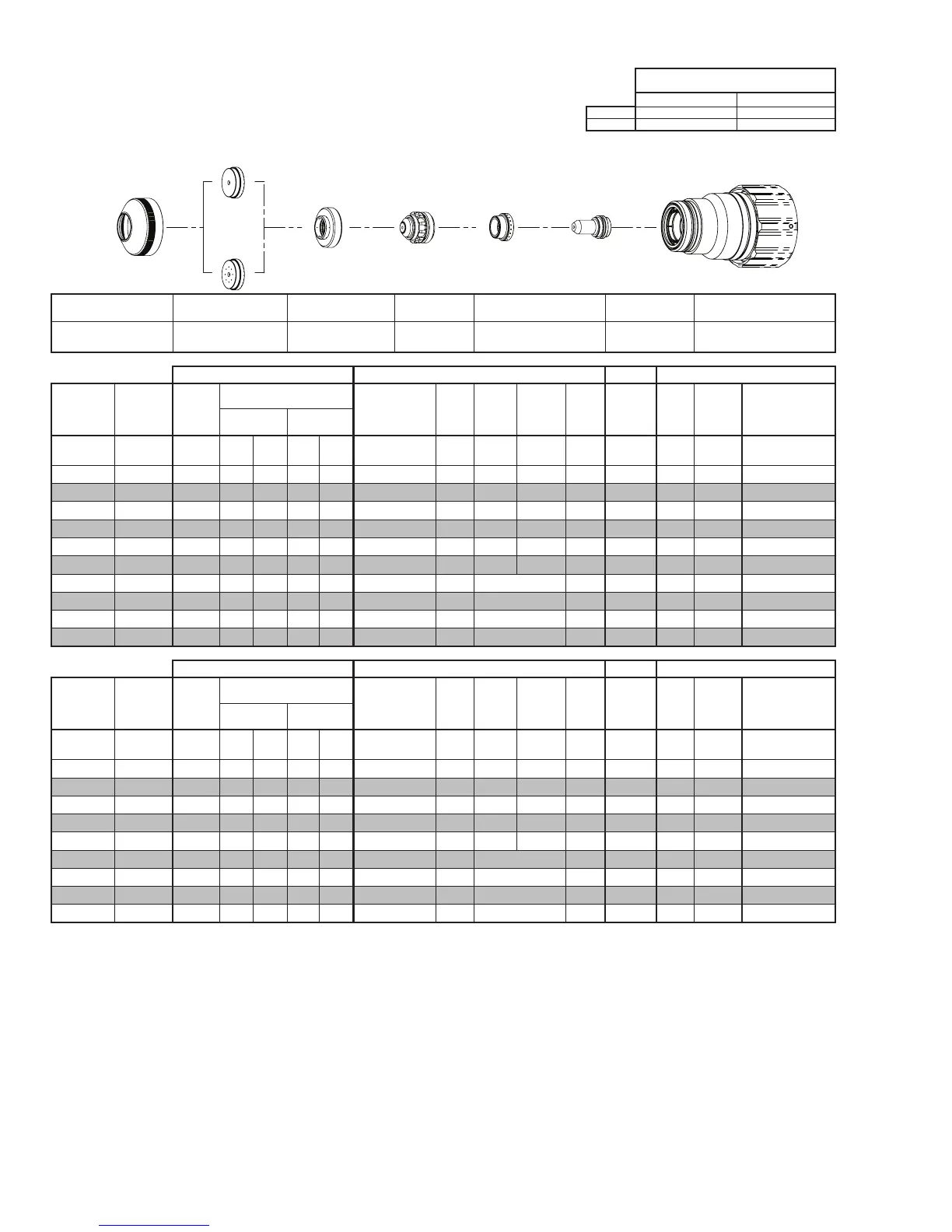

Electrode

Shield Retainer

Tip

Art # A-08567_AB

Plasma Gas

Distributor

Cartridge Assembly

This Art Is For Reference ONLY

Shield Cap

Shield Gas

Distributor

Shield Retainer Shield Cap

Shield Gas

Distributor

Tip Plasma Gas Distributor Electrode Cartridge

0559211211 0559210149 0559210082 0559210128 0559210062 0559210110 0559211300

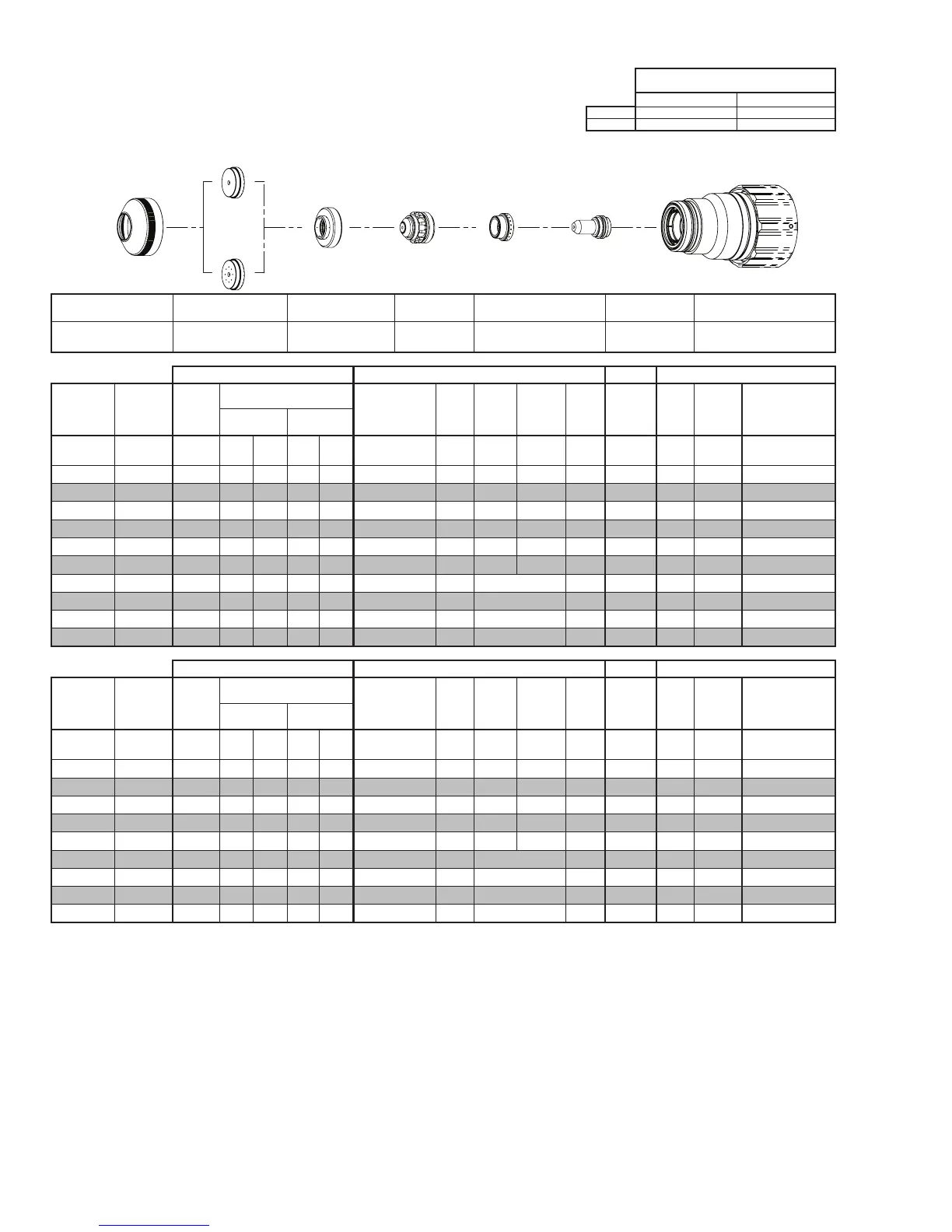

Manual Gas Control Advanced Torch Height Control (THC) Basic THC CNC Control

Eecve

Material

Thickness

Min.

Clearance

Pre Flow

Pressure

(N₂)

Cut Flow Rates / Pressures

Eecve Cut

Height

THC

Pierce

Delay

Pierce

Ignion

Height

Elevaon

Height

Control

Delay

Pierce

Height

without

Elevaon

Travel

Speed

CNC

Moon

Delay

Max Kerf Width

@ Rec. Speed

Plasma (H35) Shield (N₂)

inch (in) (psi) Ball (psi) Ball (psi) (in) (sec) (in) (in) (sec) (in) (ipm) (sec) (in)

0.375 0.080 20 120 100 NA 120 0.300 - 0.550 0.5 0.300 0.250 0.4 0.400 90 0.4 0.131

0.500 0.080 20 120 100 NA 120 0.300 - 0.550 0.8 0.300 0.250 0.3 0.400 65 0.5 0.135

0.625 0.080 20 120 100 NA 100 0.300 - 0.550 1.0 0.250 0.200 0.2 0.350 50 0.6 0.142

0.750 0.080 20 120 100 NA 100 0.300 - 0.550 1.4 0.300 0.250 0.2 0.400 40 0.8 0.143

0.875 0.080 20 120 100 NA 100 0.300 - 0.550 1.8 0.350 0.300 0.2 0.450 35 1.0 0.148

1.000 0.080 20 120 100 NA 120 0.350 - 0.550 2.0 0.350 0.300 0.2 0.450 30 1.0 0.162

1.250 0.080 20 120 100 NA 120 0.350 - 0.550 0.5 Edge Start 0.3 Edge 20 0.5 0.170

1.500 0.080 20 120 100 NA 120 0.350 - 0.550 0.5 Edge Start 0.3 Edge 16 0.5 0.175

1.750 0.080 20 120 100 NA 120 0.350 - 0.550 0.5 Edge Start 0.3 Edge 14 0.5 0.179

2.000 0.080 20 120 100 NA 120 0.350 - 0.550 0.5 Edge Start 0.3 Edge 12 0.5 0.182

Manual Gas Control Advanced Torch Height Control (THC) Basic THC CNC Control

Eecve

Material

Thickness

Min.

Clearance

Pre Flow

Pressure

(N₂)

Cut Flow Rates / Pressures

Eecve Cut

Height

THC

Pierce

Delay

Pierce

Ignion

Height

Elevaon

Height

Control

Delay

Pierce

Height

without

Elevaon

Travel

Speed

CNC

Moon

Delay

Max Kerf Width

@ Rec. Speed

Plasma (H35) Shield (N₂)

(mm) (mm) (Bar) Ball (Bar) Ball (Bar) (mm) (sec) (mm) (mm) (sec) (mm)

(mm/

min)

(sec) (mm)

10 2.0 1.4 120 6.9 NA 8.3 7.6 - 14.0 0.5 7.6 6.4 0.4 10.2 2190 0.4 3.3

12 2.0 1.4 120 6.9 NA 8.3 7.6 - 14.0 0.7 7.6 6.4 0.3 10.2 1790 0.5 3.4

15 2.0 1.4 120 6.9 NA 7.3 7.6 - 14.0 0.9 6.7 5.4 0.2 9.2 1380 0.6 3.6

20 2.0 1.4 120 6.9 NA 6.9 7.6 - 14.0 1.5 8.0 6.7 0.2 10.5 980 0.9 3.7

25 2.0 1.4 120 6.9 NA 8.1 8.7 - 14.0 2.0 8.9 7.6 0.2 11.4 780 1.0 4.1

30 2.0 1.4 120 6.9 NA 8.3 8.9 - 14.0 0.5 Edge Start 0.3 Edge 540 0.5 4.3

35 2.0 1.4 120 6.9 NA 8.3 8.9 - 14.0 0.5 Edge Start 0.3 Edge 460 0.5 4.4

40 2.0 1.4 120 6.9 NA 8.3 8.9 - 14.0 0.5 Edge Start 0.3 Edge 390 0.5 4.5

50 2.0 1.4 120 6.9 NA 8.3 8.9 - 14.0 0.5 Edge Start 0.3 Edge 310 0.5 4.6

BOLD TYPE indicates maximum piercing parameters. BOLD ITALIC indicates edge starts only.

Loading...

Loading...