100i / 200i / 300i / 400i

32 INSTALLATION Manual PN: 0560956430

Cooling System Requirements

Coolant must be added to the system on installation. The amount required varies with torch leads length.

ESAB recommends the use of its coolants 7-3580 and 7-3581 (for low temperatures).

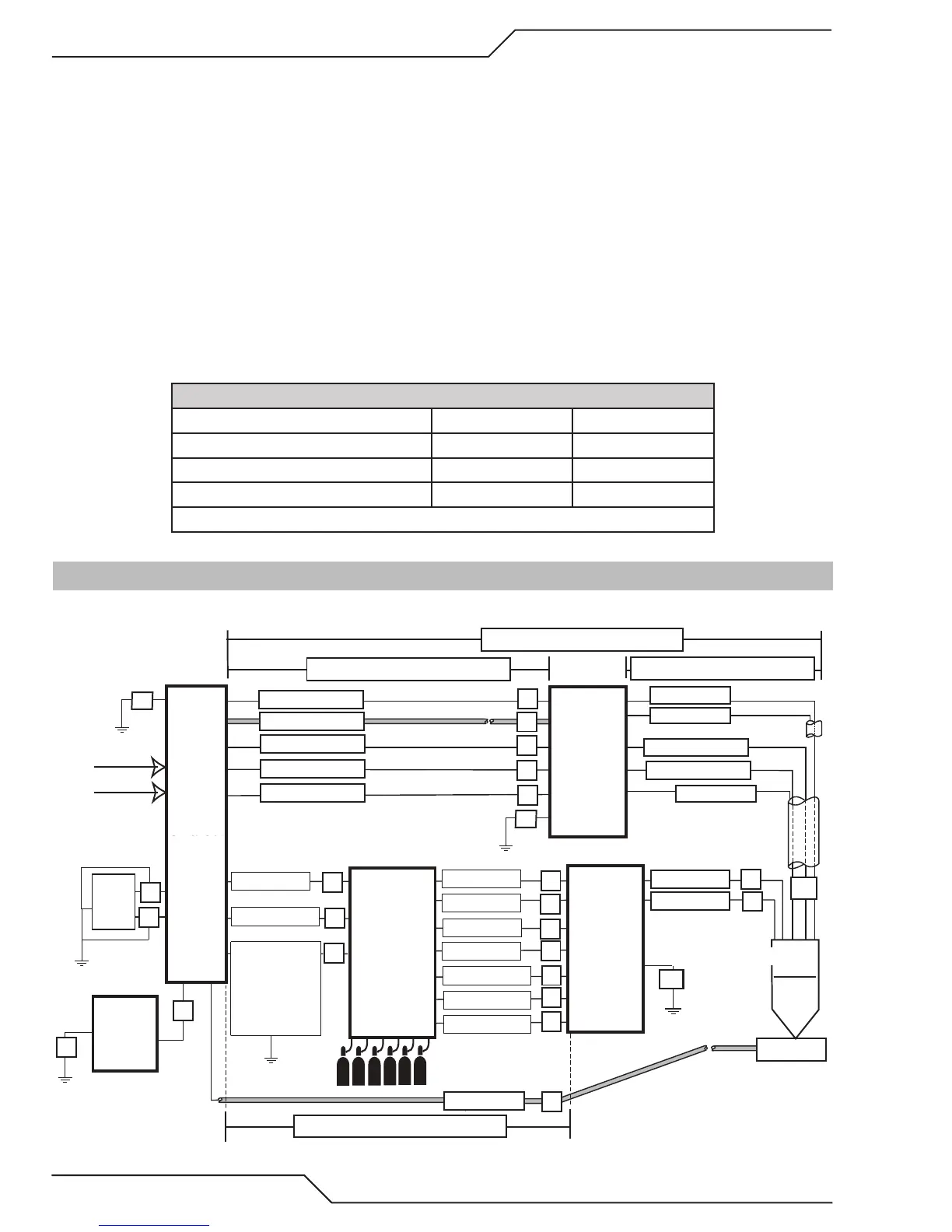

Coolant Capabilities

Cat. Number and Mixture Mixture Protects To

7-3580 ‘Extra-Cool™’ 25 / 75 10° F / -12° C

7-3581 ‘Ultra-Cool™’ 50 / 50 -27° F / -33° C

7-3582 ‘Extreme Cool™’ Concentrate* -76° F / -60° C

* For mixing with D-I Cool™ 7-3583

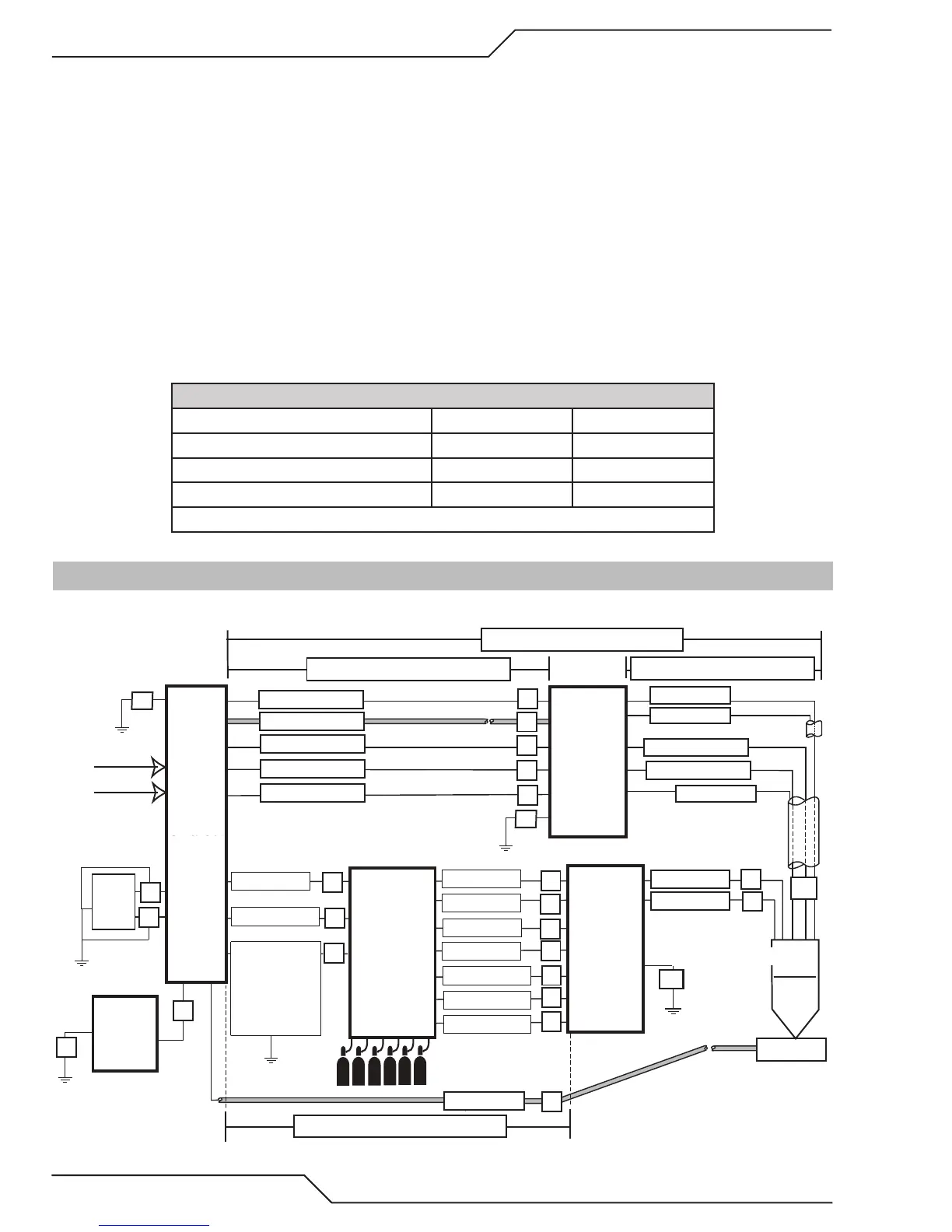

3.02 System Layout 100i - 200i Amp

Refer to section 3.08 and 3.10 for ground connections and ground cables.

Primary power

Work

CNC

Remote

Arc

Starter

Art # A-11995

Torch

Coolant Supply

Coolant Return

Control Cable

Pilot Return

Coolant Supply

Coolant Return

Plasma Gas

Shield Gas

Work Cable

DMC-3000

Gas

Console

Ultra-Cut

Power

Supply

DPC-3000

Gas

Control

Positioning Tube

Plasma Gas

Marking

Shield

Shield Gas

Negative

Pilot Return

Control Cable

100’ / 30.5 m Maximum Length

Shield

H

Q

R

U

S

A

B

C

D

E

P

K

L

O

I

J

G

175’ / 53.3 m Maximum Length

Preflow

Fiber Optic

L

Water Shield

T

125’ / 38.1 m Maximum Length

175’ / 53.3 m Maximum Length

Fiber Optic

Control Cable

F

Touch

Screen

Controller

V

W

F1

F1

F

F

Ground Cable

to PS Only

When DMC

Mounted On

Top Of PS

-If not - Earth-

Gas Supply

The customer must supply all gases and pressure regulators. Gases must be of high quality. Pressure regulators must

be double-stage and installed as close as possible to the gas console. Contaminated gas can cause one or more of the

following problems:

• Reduced cutting speed

• Poor cut quality

• Poor cutting precision

• Reduced consumables life.

• Oil or grease contamination from compressed or bottled air can cause fires in conjunction with oxygen.

Loading...

Loading...