100i / 200i / 300i / 400i

26 SPECIFICATIONS Manual PN: 0560956430

2.09 Gas Requirements

The customer will provide all gases and pressure regulators. Gases must be of high quality. Pressure regulators shall be double

stage and installed within 3 meters from the Gas Console.

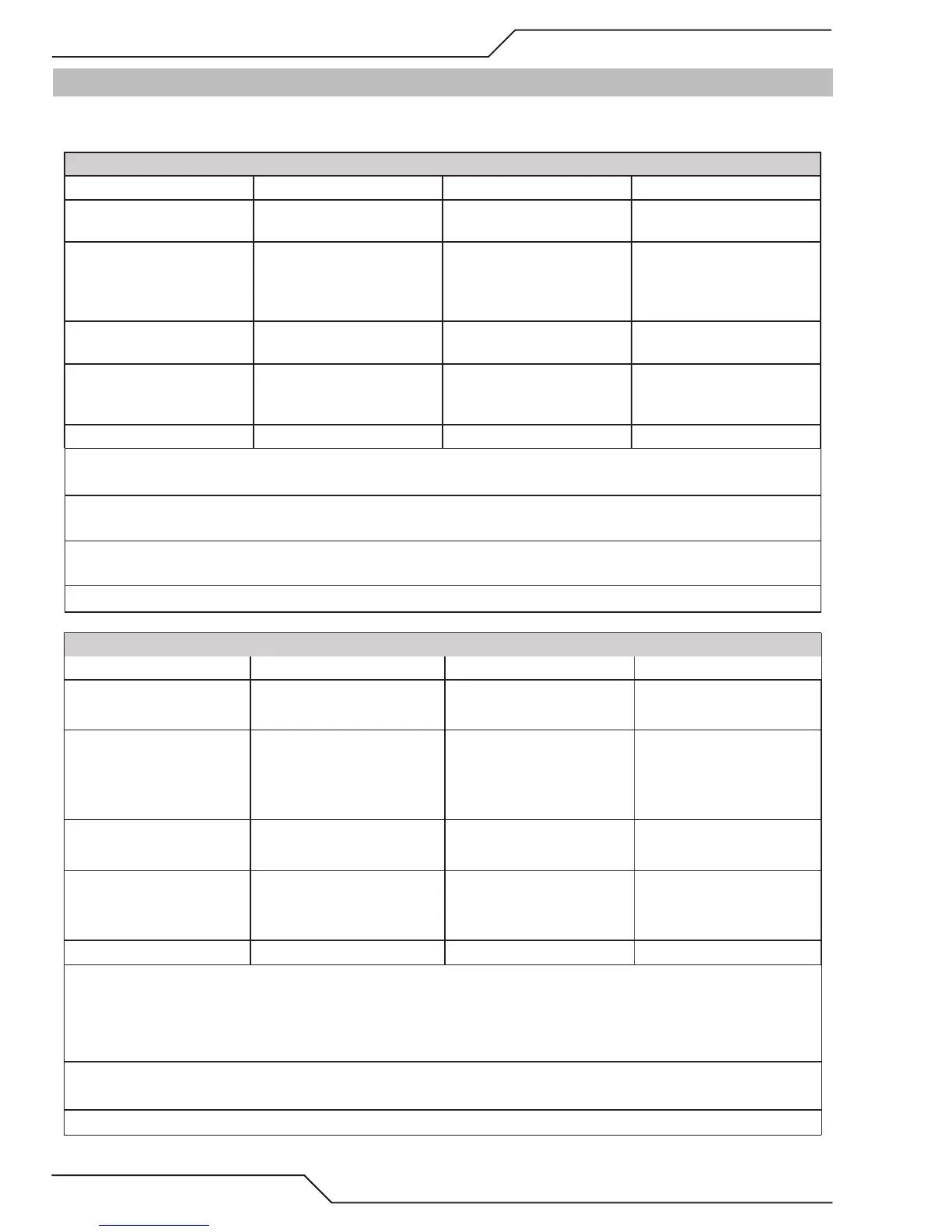

100i Power Supply: Gas Pressures, Flows, and Quality Requirements

Gas Quality Minimum Pressure Flow

O2 (Oxygen) 99.5% Purity

(Liquid recommended)

120 psi

8.3 bar / 827 kPa

70 scfh (33 lpm)

N2 (Nitrogen) 99.5% Purity

(Liquid recommended)

<1000 ppm O2, <32 ppm

H2O)

120 psi

8.3 bar / 827 kPa

200 scfh (95 lpm)

Compressed

or Bottled Air

Clean, Dry,

Free of Oil (see Note 1)

120 psi

8.3 bar / 827 kPa

250 scfh (118 lpm)

H35 (Argon-Hydrogen)

H35 = 35% Hydrogen,

65% Argon

99.995% Purity

(gas recommended)

120 psi

8.3 bar / 827 kPa

90 scfh (42.5 lpm)

H2O (Water) See Note 2 55 psi (3.8 bar) 10 gph (0.6 lpm)

Note 1: The air source must be adequately filtered to remove all oil or grease. Oil or grease

contamination from compressed or bottled air can cause fires in conjunction with oxygen.

For filtering; a coalescing filter able to filter to 0.01 microns should be placed as close as

possible to the gas inlets on the Gas Control Module.

Note 2: The tap water source does not need to be deionized, but in water systems with extremely high mineral content a

water softener is recommended. Tap water with high levels of particulate matter must be filtered.

Note 3: Water Pressure Regulator No. 8-6118 is recommended to ensure proper water pressure.

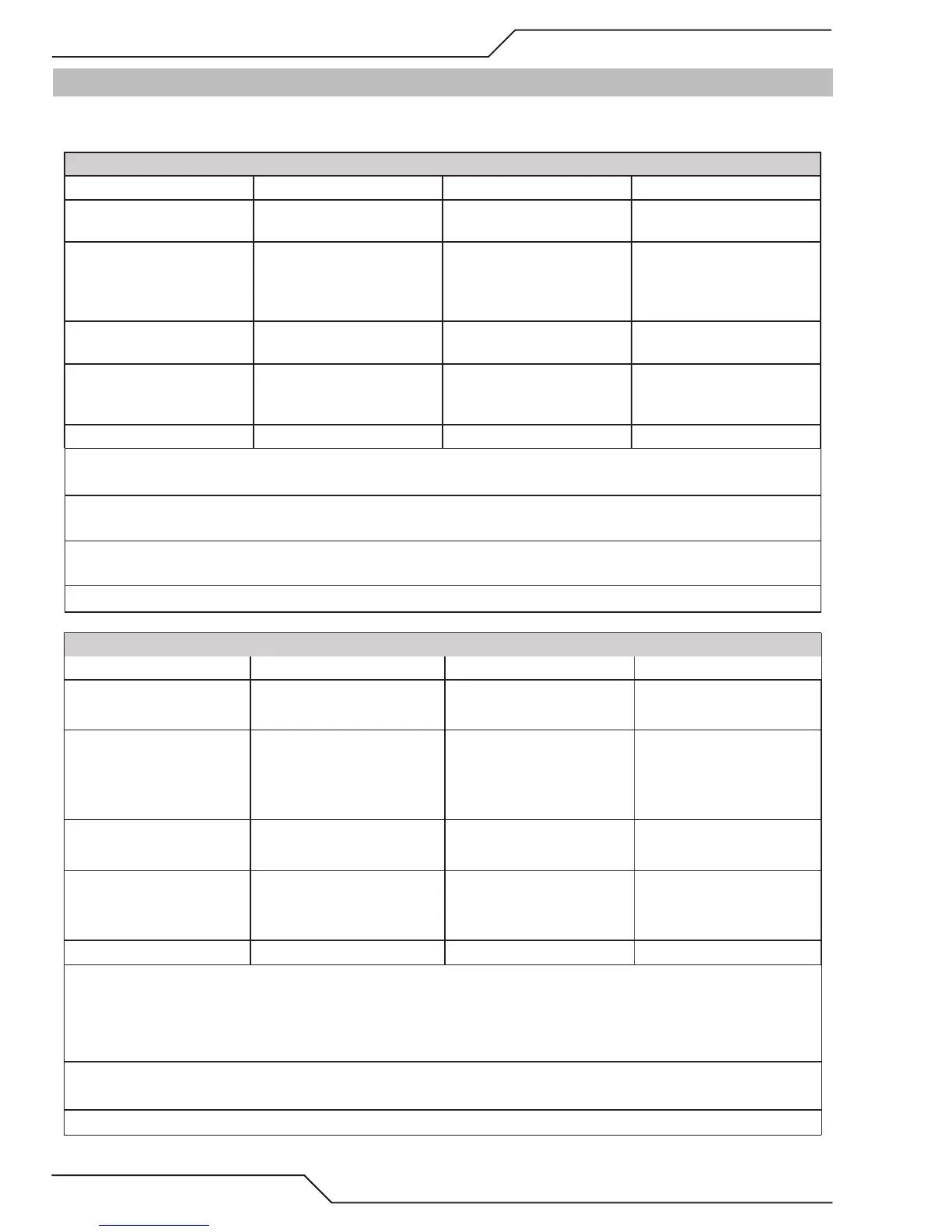

200i Power Supply: Gas Pressures, Flows, and Quality Requirements

Gas Quality Minimum Pressure Flow

O

2

(Oxygen)

99.5% Purity

(Liquid recommended)

120 psi

8.3 bar / 827 kPa

200 scfh (95 lpm)

N

2

(Nitrogen)

99.5% Purity

(Liquid recommended) <1000

ppm O

2

, <32 ppm H

2

O)

120 psi

8.3 bar / 827 kPa

200 scfh (95 lpm)

Compressed

or Bottled Air

Clean, Dry,

Free of Oil (see Note 1)

120 psi

8.3 bar / 827 kPa

450 scfh (212.4 lpm)

H35 (Argon-Hydrogen)

H35 = 35% Hydrogen,

65% Argon

99.995% Purity

(gas recommended)

120 psi

8.3 bar / 827 kPa

200 scfh (95 lpm)

H

2

O (Water) See Note 2 55 psi (3.8 bar) 10 gph (0.6 lpm)

Note 1: The air source must be adequately filtered to remove all oil or grease. Oil or grease

contamination from compressed or bottled air can cause fires in conjunction with oxygen.

For filtering, a coalescing filter able to filter to 0.01 microns should be placed as close as

possible to the gas inlets on the Gas Control Module.

Note 2: The tap water source does not need to be deionized, but in water systems with extremely high mineral content a

water softener is recommended. Tap water with high levels of particulate matter must be filtered.

Note 3: Water Pressure Regulator No. 8-6118 is recommended to ensure proper water pressure.

Loading...

Loading...