100i / 200i / 300i / 400i

38 INSTALLATION Manual PN: 0560956430

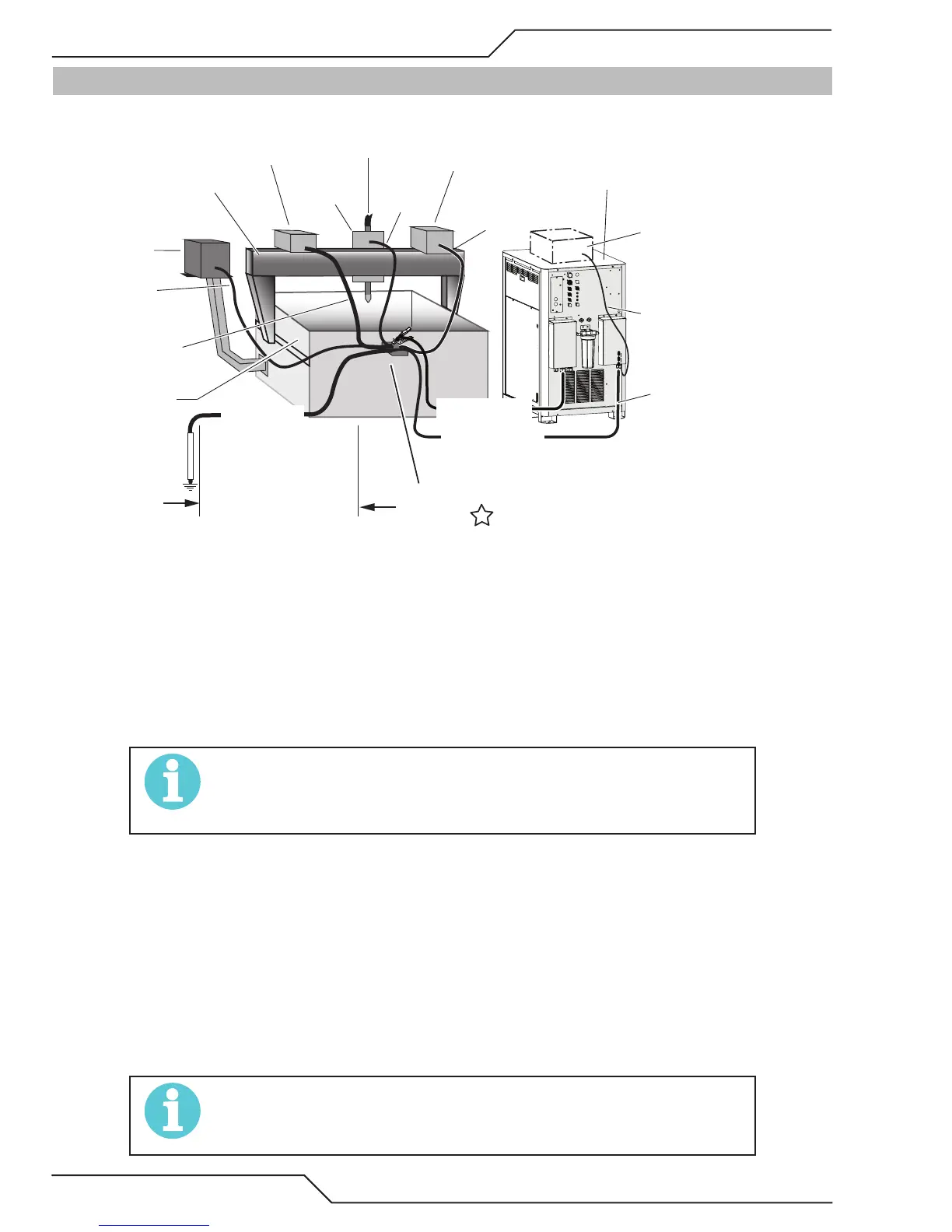

3.10 Ground Connections

Remote Arc

Starter (RAS-1000)

Power Supply

iCNC

Star Ground on Cutting Table

Note: The gas control

module can be mounted

on top of the power

supply. If it is, it should

be grounded directly to

the power supply with

#4 AWG ground, (F).

Any location requires

grounding the power

supply to the ‘Star’

ground with the 1/0

Ground Cable (F1).

Gas Control Module

Primary location

Art # A-11875.AC

‘Star’

Ground

0 - 10 ft (0 - 3 m) Ideal

20 ft (6 m) Maximum

1/0

Ground Cable

Earth Ground

Rod

Customer supplied

A good ground will be

less than 3 ohm. Ideal 1.

1/0

Ground Cable

(F1)

Cutting Machine / Gantry

Cutting Table

Torch

#4 AWG

Ground

(F)

#4 AWG

Ground

Lifter

1/0 Ground Cable

3/0 Work Cable

#4 AWG

Ground

A. Electromagnetic Interference (EMI)

Pilot arc starting generates a certain amount of electromagnetic interference (EMI), commonly called RF noise. This RF noise

may interfere with other electronic equipment such as CNC controllers, remote controls, height controllers, etc. To minimize RF

interference, follow these grounding procedures when installing automation (mechanized) systems:

B. Grounding

1. The preferred grounding arrangement is a single point or “Star” ground. The single point, usually on the cutting table, is

connected with 1/0 AWG (European 50 mm

2

) or larger wire to a good earth ground (measuring less than 3 ohms; an ideal

ground measures 1 ohm or less. Refer to paragraph ‘C’, Creating An Earth Ground. The ground rod must be placed as close

as possible to the cutting table, ideally less than 10 ft (3.0 m), but no more than 20 ft (6.1 m) from the cutting table.

NOTE!

All ground wires should be as short as possible. Long wires will have increased

resistance to RF frequencies. Smaller diameter wire has increased resistance to

RF frequencies, so using a larger diameter wire is better.

2. Grounding for components mounted on the cutting table (CNC controllers, height controllers, plasma remote controls, etc.)

should follow the manufacturer’s recommendations for wire size, type, and connection point locations.

For ESAB components (except Remote Arc Starter and Gas Control Module) it is recommended to use a minimum of 10 AWG

(European 6 mm

2

) wire or flat copper braid with cross section equal to or greater than 10 AWG connected to the cutting table

frame. The Remote Arc Starter uses 1/0 earth ground wire and the Gas Control Module should use minimum # 4 AWG wire.

The connection point must be to clean bare metal; rust and paint make poor connections. For all components, wires larger

than the recommended minimum can be used and may improve noise protection.

3. The cutting machine frame is then connected to the “Star” point using 1/0 AWG (European 50 mm

2

) or larger wire.

4. The plasma power supply work cable (see NOTE) is connected to the cutting table at the single point “Star” ground.

NOTE!

Do Not connect the work cable directly to the ground rod. Do not coil up excess

ground or power cables. Cut to proper length and reterminate as needed.

Loading...

Loading...