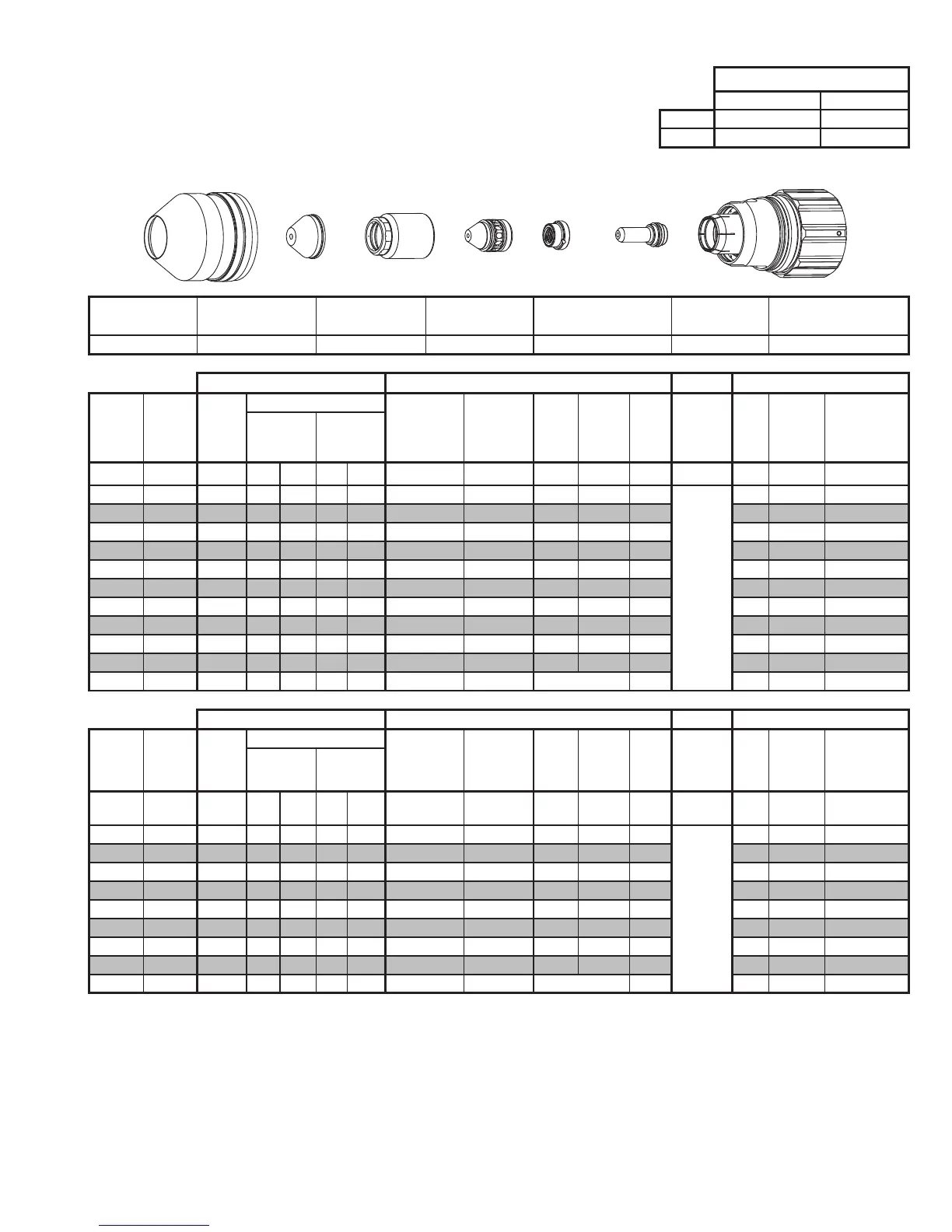

Manual 0560956430 211 TORCH DATA 100i-400i

Aluminum

400A Bevel Cut

N₂ Plasma / H₂O Shield

Flow Rates

Shield Cup Shield Cap

Shield Gas

Distributor

Tip Plasma Gas Distributor Electrode Cartridge

Manual Gas Control Advanced Torch Height Control (THC) Basic THC CNC Control

Eecve

Material

Thickness

Min.

Clearance

Pre Flow

Pressure

(N2)

Cut Flow Rates / Pressures

Eecve Cut

Height

THC Pierce

Delay

Pierce

Ignion

Height

Height

Delay

Pierce

Height

without

Elevaon

Travel

Speed

CNC

Moon

Delay

Max Kerf Width

@ Rec. Speed

Plasma (N₂) Shield (H₂O)

inch (in) (psi) Ball (psi) Ball (psi)* (in) (sec) (in) (in) (sec) (in) (ipm) (sec) (in)

Not Recommended without

Elevaon Height

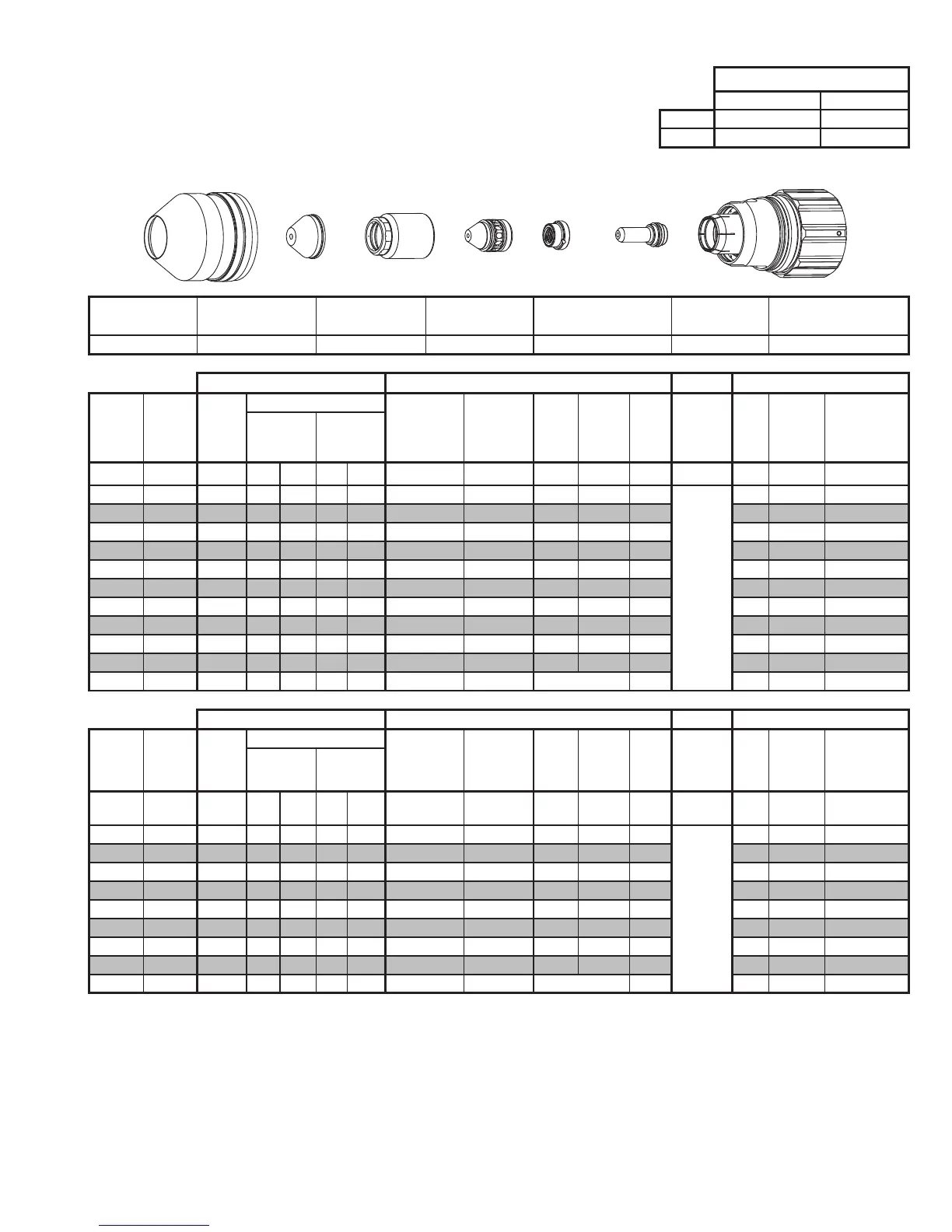

Manual Gas Control Advanced Torch Height Control (THC) Basic THC CNC Control

Eecve

Material

Thickness

Min.

Clearance

Pre Flow

Pressure

(N2)

Cut Flow Rates / Pressures

Eecve Cut

Height

THC Pierce

Delay

Pierce

Ignion

Height

Height

Delay

Pierce

Height

without

Elevaon

Travel

Speed

CNC

Moon

Delay

Max Kerf Width

@ Rec. Speed

Plasma (N₂) Shield (H₂O)

(mm) (mm) (Bar) Ball (Bar) Ball (Bar)* (mm) (sec) (mm) (mm) (sec) (mm)

(mm/

min)

(sec) (mm)

Not Recommended without

Elevaon Height

BOLD TYPE indicates maximum piercing parameters. BOLD ITALIC indicates edge starts only.

BOLD TYPE indicates maximum piercing parameters.

* Pressure of the water supply line should be regulated by customer pressure regulator.

Note1: Ohmic height sensing is not recommended with water shield. Water on the plate interferes electrically with the ohmic sensing circuit.

Note2: Water source used for shield must be demineralized.

This Art Is For Reference Only

Shield Cup

Shield Cap

Shield Gas

Distributor

Tip

Gas

Distributor

Electrode

Cartridge Assembly

Art# A-10445

Loading...

Loading...