-- 1 2 --

bi09dinte

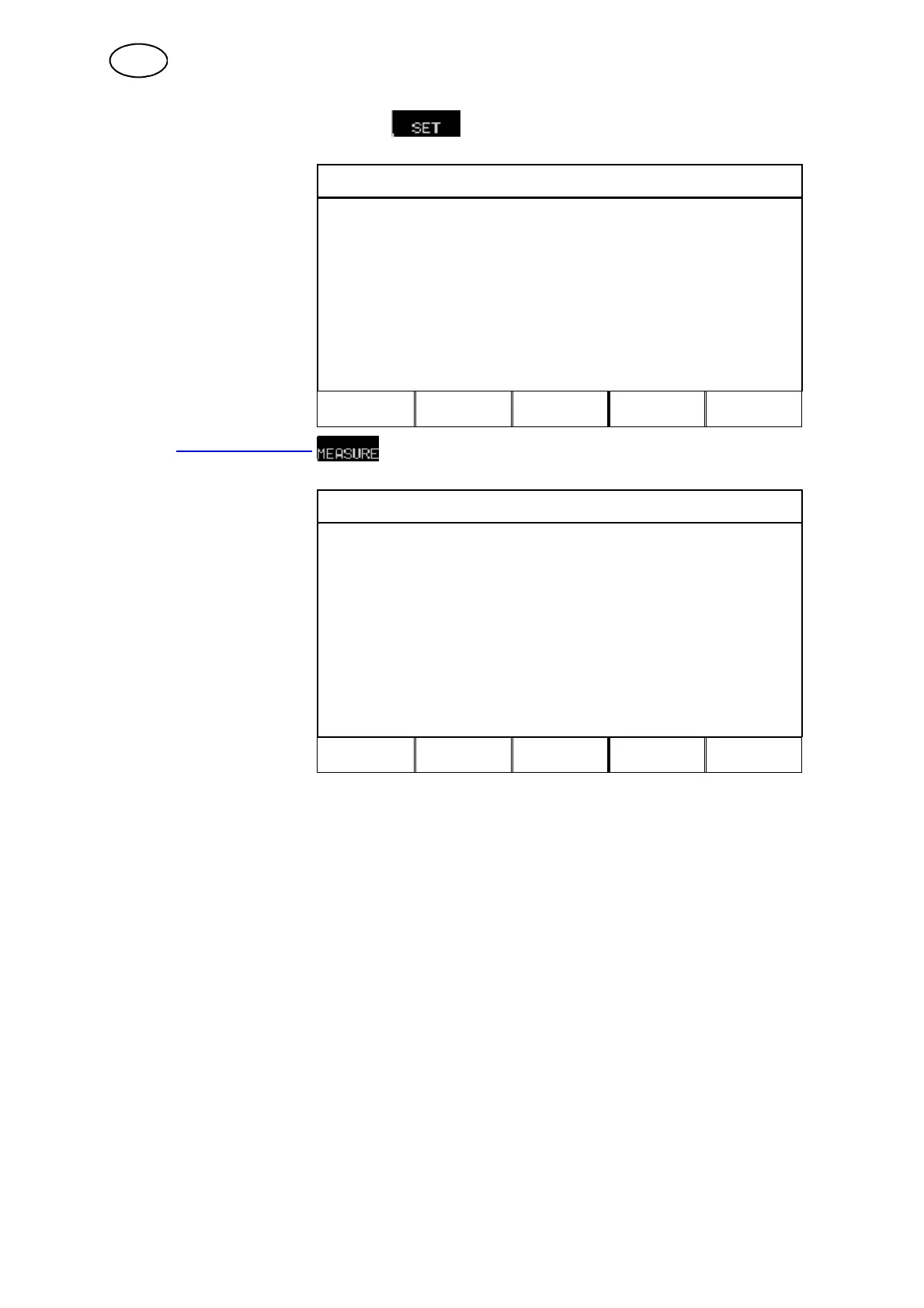

2.1.2 Weld data setting menu

In the WELD DATA

WELD DATA SETTING

you can

change various weld

parameters. The menu’ s

appearance differs,

depending on which weld

process you have selected.

In this example it is

MIG/MAG welding with

dip/spray.

VOLTAGE: # 26.8 (+0.0) V

WIRE SPEED: * 6.0 m/min

INDUCTANCE: 80 %

SYNERGIC MODE PÅ

START DATA...

STOP DATA...

LIMITS

CRATR

FILL

HOT

START

4--

STROKE

QUIT

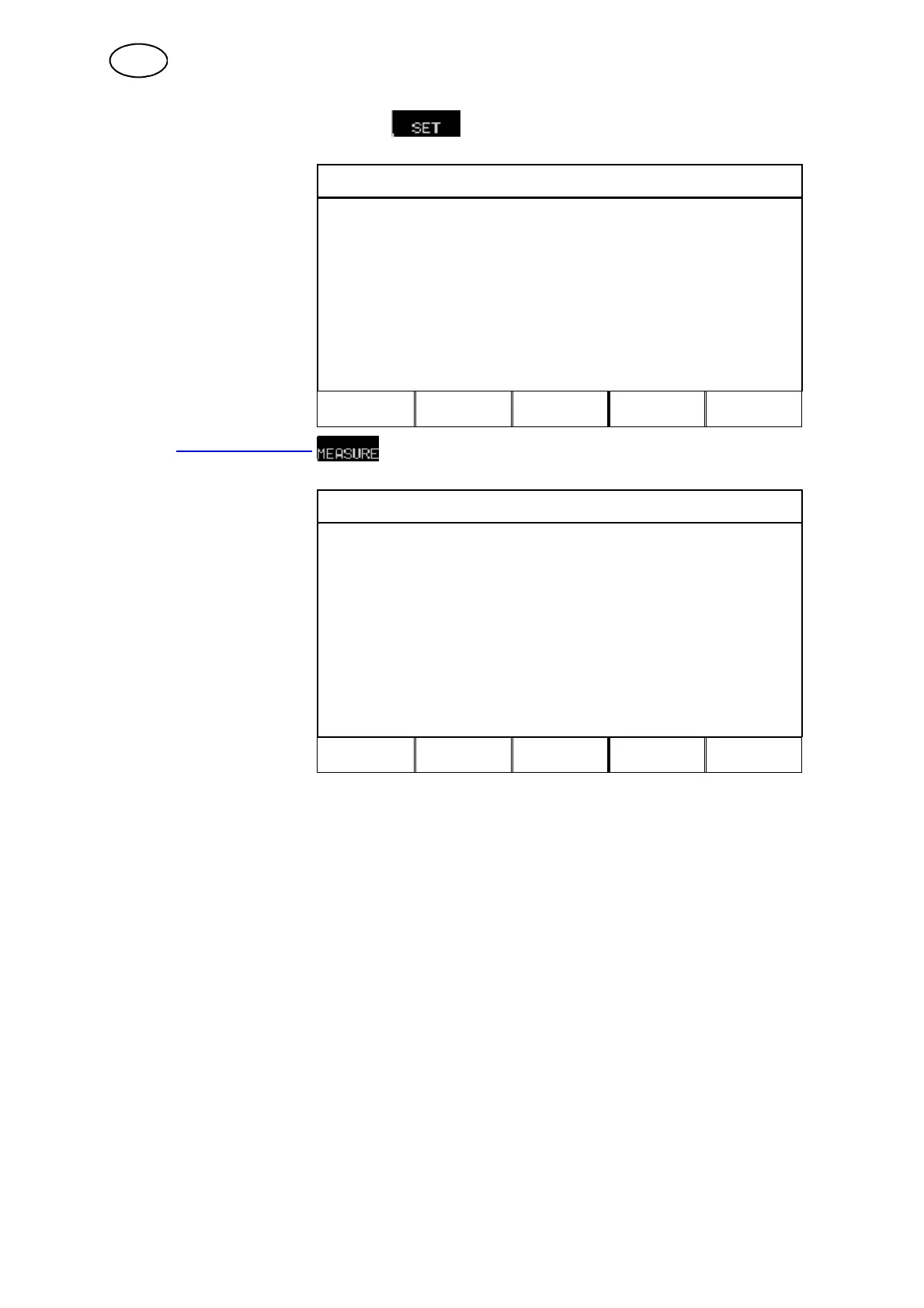

2.1.3 Measure image

In the MEASURE IMAGE

DIP/SPRAY. Fe, CO2, 1.2 mm

you can see

e measure

values of various weld

parameters during welding.

The measured values

remain in the display even

after welding has been

completed.

You can move to other

menus without losing the

measured values.

# 0.0 Volt

0Amp

* 6.0 m/min

↓

CRATER

FILL

HOT

START

4--

STROKE

REM

2ND

FUNCT

The arrow in the bottom right--hand corner of the display indicates that there is more

information available.

In the measure image you can change the value of certain parameters. Which

parameters these are depends on which weld process has been set. The parameter

values that can be adjusted are always marked with # or *.

When values are changed while no welding is in progress, the measured values will

change to zero to avoid misunderstandings regarding which settings correspond to

the measure result.

TIP!

In pulsing you can select whether the voltage value is displayed as an average value

or peak value. This setting can be defined under MIG/MAG basic settings, see

chapter 12.3.

GB

Loading...

Loading...