-- 3 0 --

bi09d1e2

Welding example B

In this exemple we will weld a 6mmplatewith 1.2 mm aluminium wire and argon

shielding gas.

Make the following settings with the controller:

Process MIG SUPERPULSE MIG SUPERPULSE

Phase Primary Secondary

Method Pulse Pulse

Wire type Al Mg Al Mg

Shielding gas Ar Ar

Wire dimension 1.2 mm 1.2 mm

Voltage (+ 1.0V) (+ 2.0V)

Wire feed speed 12.5 m/min 9.0 m/min

Phase weld time 0.15 s 0.15 s

The primary and secondary phase time is 0.15 s + 0.15 s = 0.3 s.

The difference in wire feed speed is 12.5 m/min -- 9.0 m/min = 3.5 m/min.

8 MEMORY MANAGEMENT

8.1 How the controller works

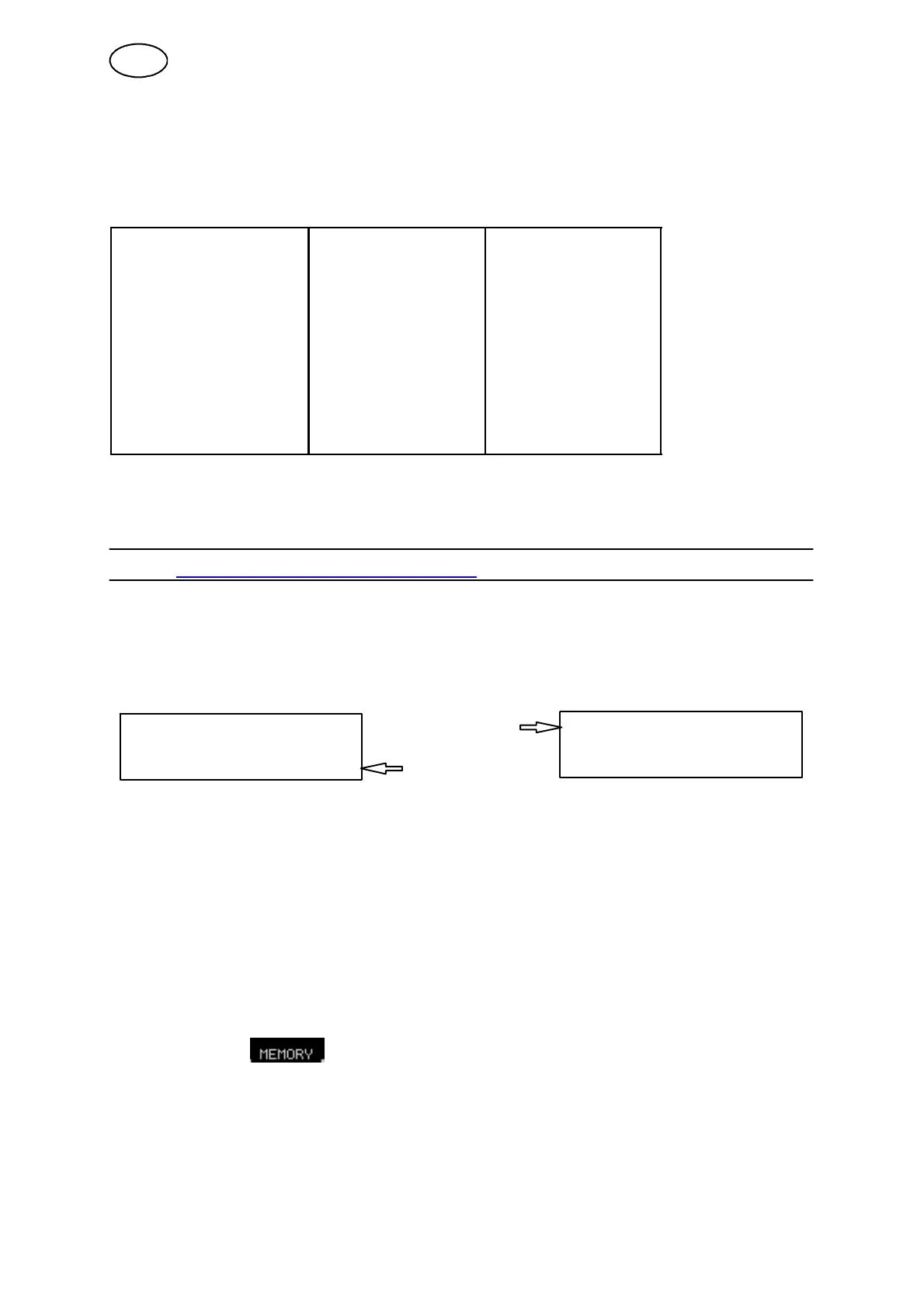

The controller consists in principle of two units: primary memory and weld data

memory.

Store

Primary memory Weld data memory

Recall

In the primary memory you create a complete set of weld data settings, which can be

saved in the weld data m emory.

During welding it is always the content of the working memory that controls the

process. It is therefore also possible to recall a weld data setting from the weld data

memory to the working memory.

Note that the working memory always contains the last weld data settings that were

defined. T hey may have been recalled from the weld data memory, or they can be

individually modified settings. In other words, the working memory is never empty or

”reset to zero”.

M a i n m e n u -- -- >

In the controller you can store up t o 255 sets of weld data. Each set is given a

number from 1 to 255.

You can also delete and copy data sets, and you can also recall a set of weld data

to the working memory.

Here are some examples to show how to store, recall, copy and delete.

GB

Loading...

Loading...