-- 2 6 --

bi09d1e2

5.3 Other function explanations

5.3.1 Gas purge

The gas purge function is used when measuring the gas flow or to purge the gas

hoses of any air and moisture before welding commences. Gas purging proceeds as

long as the key is pressed down, and is conducted without current and wire feed

being switched on.

-- Gas purging is enabled in the measure image.

6 CARBON, ARC AIR

Mig 4000i, Mig 4500i, Mig 5000i

Main menu ----> Process

Carbon, Arc air involves the use of a special electrode consisting of a carbon bar

with a copper case.

An arc is formed between the carbon bar and the workpiece, air is supplied to blow

away the melted material, and a seam is formed.

The table on page 69 shows the electrode diameters that can be selected for

carbon, arc air.

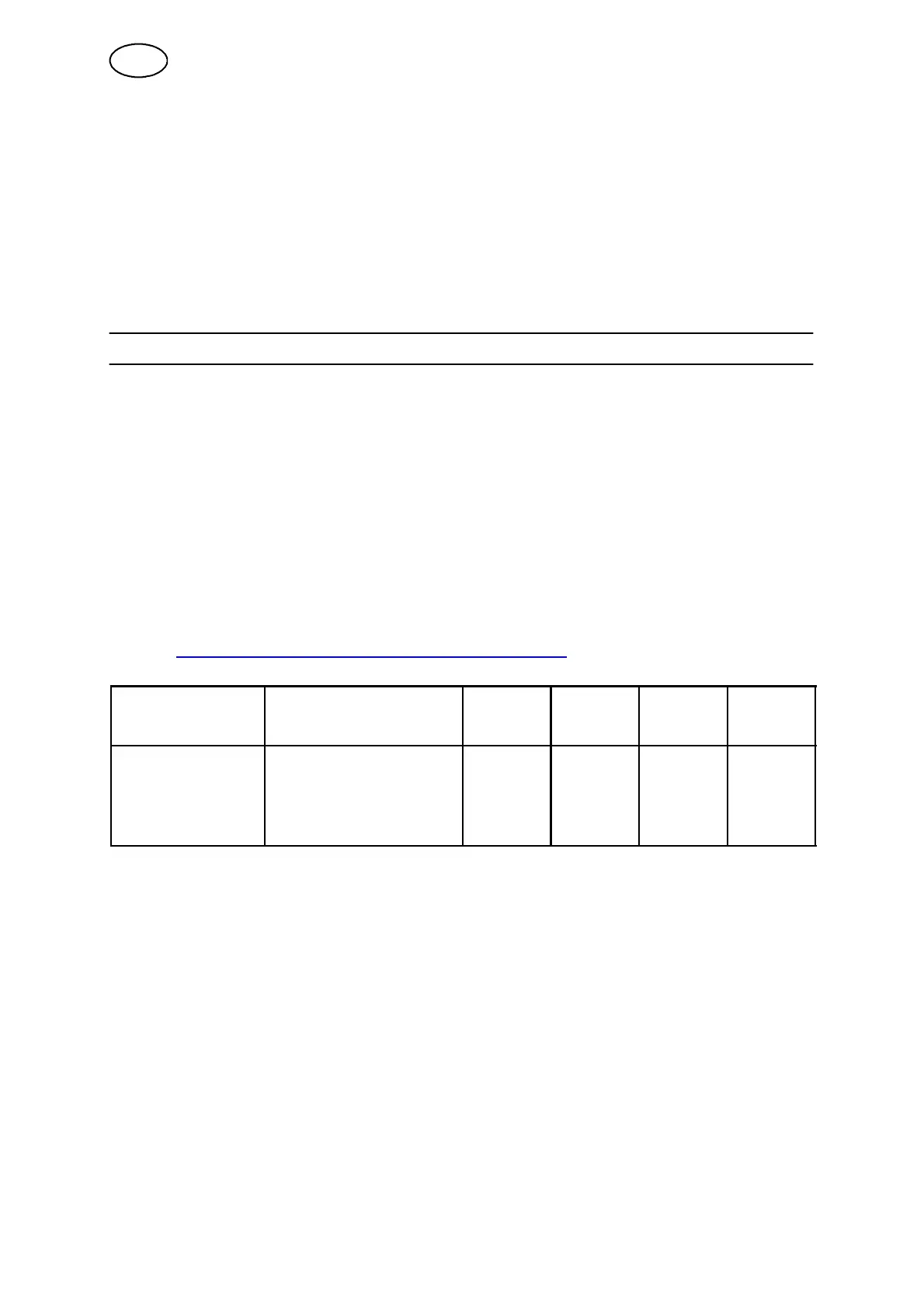

6.1 Settings in the weld data setting menu

Settings Setting range In steps

of:

Values

after reset

Synergic

depend -

ent

Adjust--

able in

synergic

Voltage 8--60V 1V 39 V x x

Inductance 0 -- 100% 70% x

Control type 1--5 1 1 x

Synergic mode* ON or OFF -- ON -- --

*) Default synergic line: 5.0 mm electrode (carbon bar).

6.2 Function explanations

6.2.1 Voltage

Higher current produces wider and deeper penetration into the workpiece

Voltage is set in either the measure image, the weld data setting menu, or the fast

mode menu.

6.2.2 Inductance

Note! This setting should not be changed.

6.2.3 Regulator typ e

Note! This setting should not be changed.

GB

Loading...

Loading...