-- 5 3 --

bi09d1e2

12.5.6 Quality data logging

To enable you to use this function, insert a compact flash card into the controller, see

the 10 ”File manager”. chapter.

Activating/deactivating logging of quality data

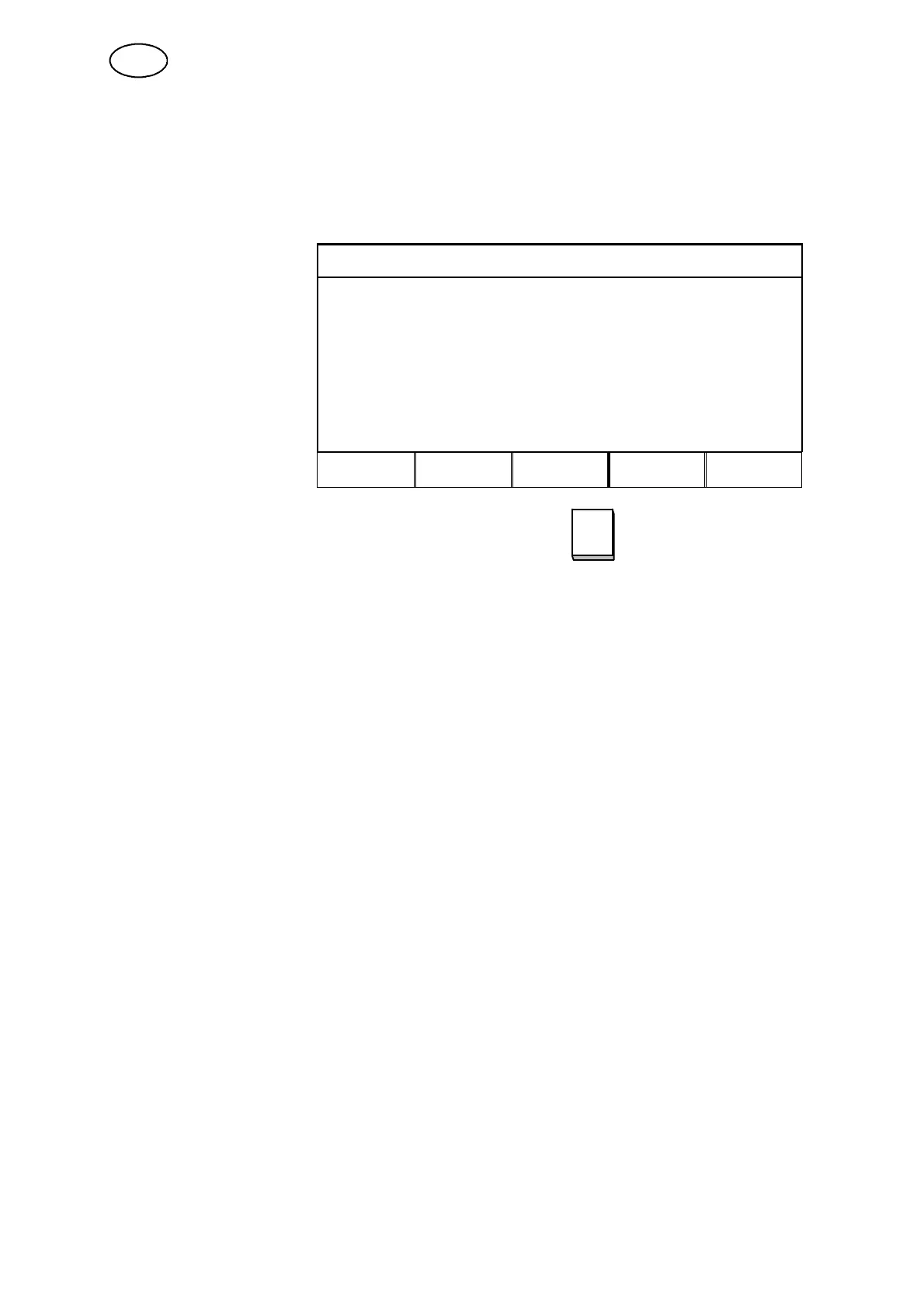

CONFIGURATION -- GENERAL DEFAULTS

Use the arrow keys to

highlight QUALITY DAT A

LOG TO FILE and press

ENTER.

FAST MODE SO FT BUTTONS

DOUBLE START SOURCES: OFF

PANEL REMOTE ENABLE OFF

AUTO SAVE MODE: OFF

TRIGGER WELDDATA SWITCH

QUALITY DATA LOG TO FILE ON

QUIT ENTER

Highlight ON and press ENTER to activate. Highlight OFF and

press ENTER to deactivate.

ON

OFF

Once logging has been activated, quality data is saved continuously on the compact

flash card, i.e. after each weld, data about it is automatically saved in a file on the

card. With the first weld after logging has been started, a file is generated into which

data on all subsequent welds is also saved.

For a description of quality data, see the 13 ”Quality functions” chapter, and for

information on what the quality data files contain, see the 10.8 ”Quality data files

content” chapter.

Naming quality data files with continuous incorporation

The files are named using the format CQdata050621_01.aqd. The file name always

starts with CQdata (specific to continuously saved quality data) and ends with .aqd

(common to all quality data files). T he figures in the example denote that it is a file

generated on 21 June 2005 and that was the first file generated on that day.

If logging is suspended and resum e d on the same day, the later file will have a

higher serial number. In this example, the name of the new file would be

CQdata050621_02.aqd.

If logging continues into the next day, a new file will be initiated with the day’s date in

the name. In this example, the name of the new file would be CQda-

ta050622_01.aqd.

The file is placed in a folder called QData. QData is generated automatically when

you insert a compact flash card.

GB

Loading...

Loading...