-- 6 4 --

bi09d1e2

The following also applies:

S A higher weld data number must contain higher values for voltage and

wire feed speed than the weld data number that precedes it.

S The weld parameters inductance, regulator type and hot start-- voltage

must have the same values in all four weld data numbers.

S Define the number of co--ordinates that are needed, and then proceed to chapter

16.2 ”Specifying the valid wire/gas combination”.

16.1.2 Pulsing

S Call up the main menu and select the MIG/MAG method PULSE.

S Key in the desired values for voltage and wire feed speed for the first

co--ordinate.

S Call up the memory menu and store the first co--ordinate as weld data number

96.

S The two co--ordinates for a pulse line must be saved as numbers 96 and 97.

The following also applies:

S A higher weld data number must contain higher values for voltage, wire

feed speed, pulse frequency, pulse amplitude and background current

than the weld data number that precedes it.

S The weld parameters pulse time, hot start--voltage,Ka,Kiand ”slope”

must have the same value in both weld data numbers.

S Define the number of co--ordinates that are needed, and then proceed to chapter

16.2 ”Specifying the valid wire/gas combination”.

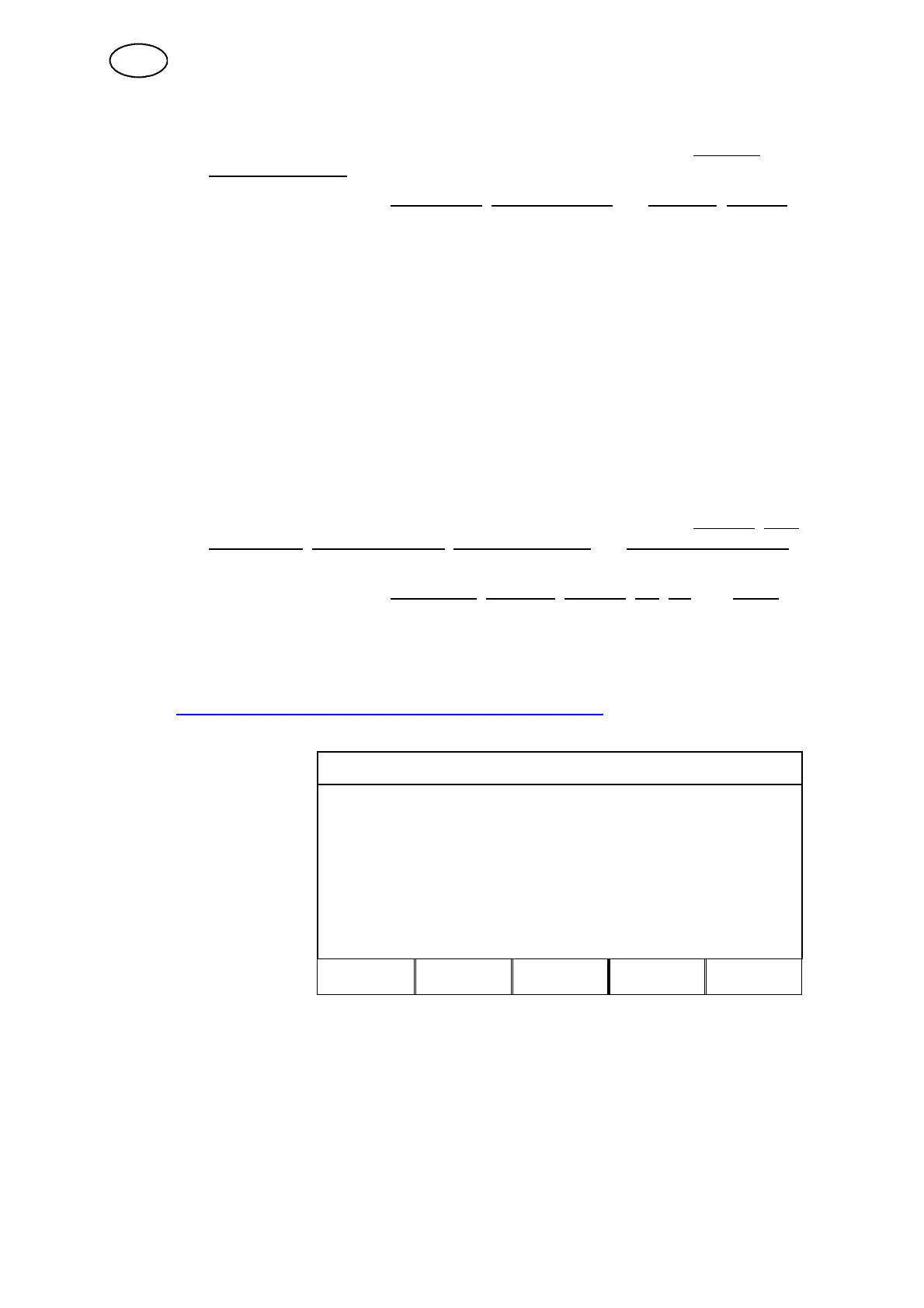

16.2 Specifying the valid wire/gas combination

MAKE CUSTOMISED SYNERGIC LINES

Move the cursor to the line

for WIRE TYPE and press

ENTER.

WIRE TYPE Fe

SHIELDING GAS: CO2

WIRE DIAMETER : 1.2 mm

STORED NEW LINE FROM

WELD DATA MEMORY 96, 97

DELETE SYNERGIC LINE

QUIT ENTER

GB

Loading...

Loading...