KT5500 5-

1

/

2

” Tong & CLInCHER® BaCKup

SECTIon ConTEnTS

3.18

TECHnICaL ManuaL

MaInTEnanCE

Mechanical Assembly Procedure (Continued):

61. Attachtherigidslinghangerweldments(LHweldment=PN101-0150,RHweldment=PN101-0151)tothetopplateusing

two3/8”NCx1-3/4”bolts(outside),two3/8”NCx1”bolts(inside),andfour3/8”lockwashersperhanger.

62. Installinletcouplingsupportassembly(PN1050-C-175)tothetopplate,betweentheRHpinionidlerandRHrotaryidler,

usingtwo3/8”NCx1”hexboltsand3/8”lockwashers.Attachtheoutletcouplingsupportbase(PN101-0023)tothetop

platerightofthepinionbearingcapusingtwo3/8”NCx1”hexboltsand3/8”lockwashers,andattachtheadjustingplate

(PN101-0022)tothesupportbaseusingtwo3/8”NCx1”hexbolts,two3/8”flatwashers,andtwo3/8”UNCnylocknuts.

63. Installtwohydraulicvalvemountweldments(PN101-1442)tothetopplateoneithersideofthebrakebandretainerusing

one3/8”NCx1”hexboltand3/8”lockwasherperweldment.

64. Installthehydraulicvalveassemblytothevalvemountweldmentsusingone1/2”NCx4-1/2”hexboltand1/2”narrowflat

washerpervalvemount.Installmaininletandoutletlines,andtheremainderofthehydraulicconnections.Seethehydraulic

schematicforhydraulicconnections.

65. Slidethemasterliftinglink(PN02-0516)overtheadjustmenthelix(PN1053-1-H),andinstalltheadjustmenthelixintherigid

slingweldment(PN101-0112)usinga3/4”UNCx8”hexboltand3/4”UNCnylocknut.

66. Useacranetohoisttherigidslingweldment.Connecttherigidslingweldmenttotherigidslingmountinglugswithrigidsling

pins(PN1053-C-1C).Secureeachpinwithtwo0.148”x2.938”hitchpins.

67. Threada3/4”UNChexnutontoeachoftworigidslinglevelingadjustmentweldments(PN1053-C-1L).Threadtheleveling

adjustmentweldmentsintothefrontoftherigidslingweldmentmountingbrackets,roughlyadjustingthemsotherigidsling

isapproximatelyperpendiculartothetopplateofthetong(seeillustration3.H.10).

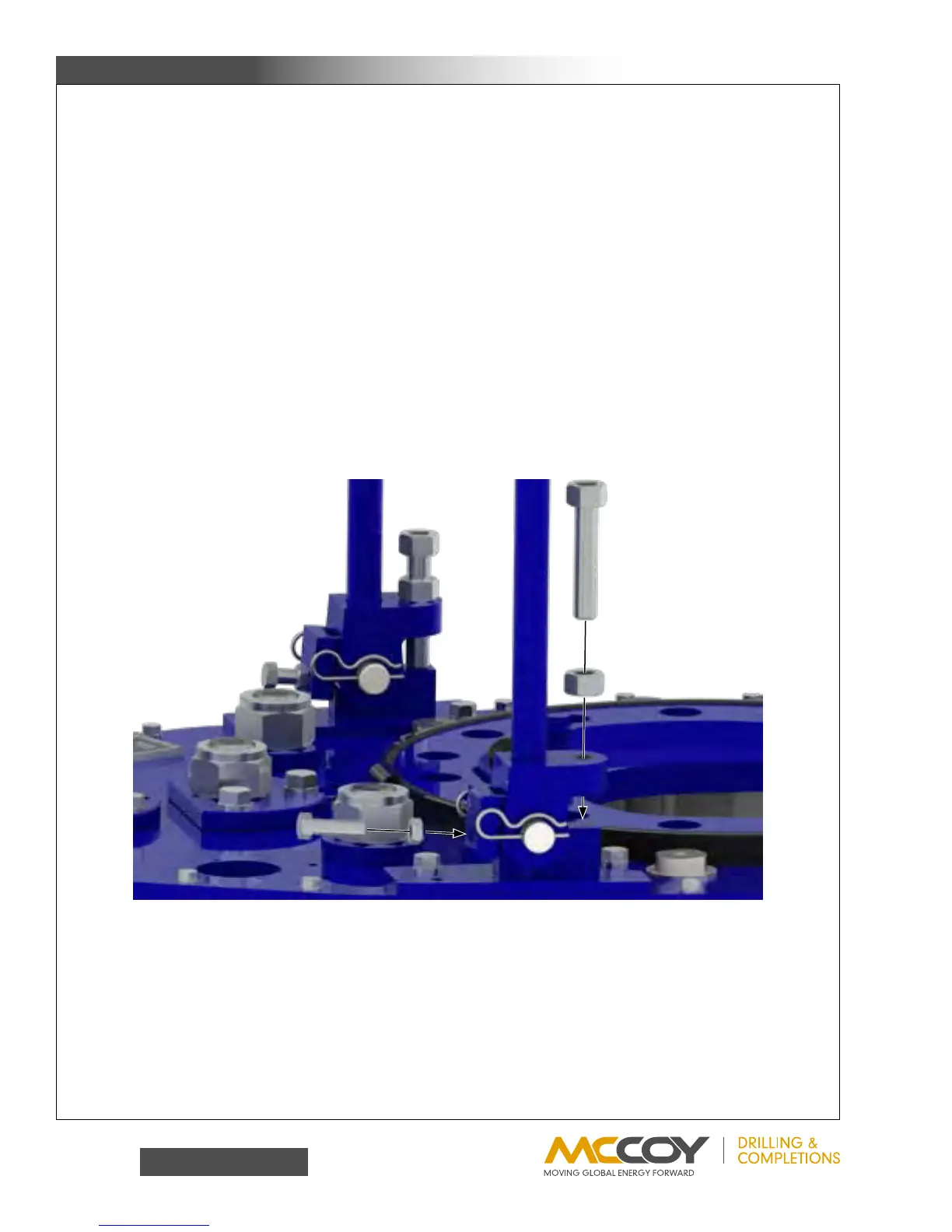

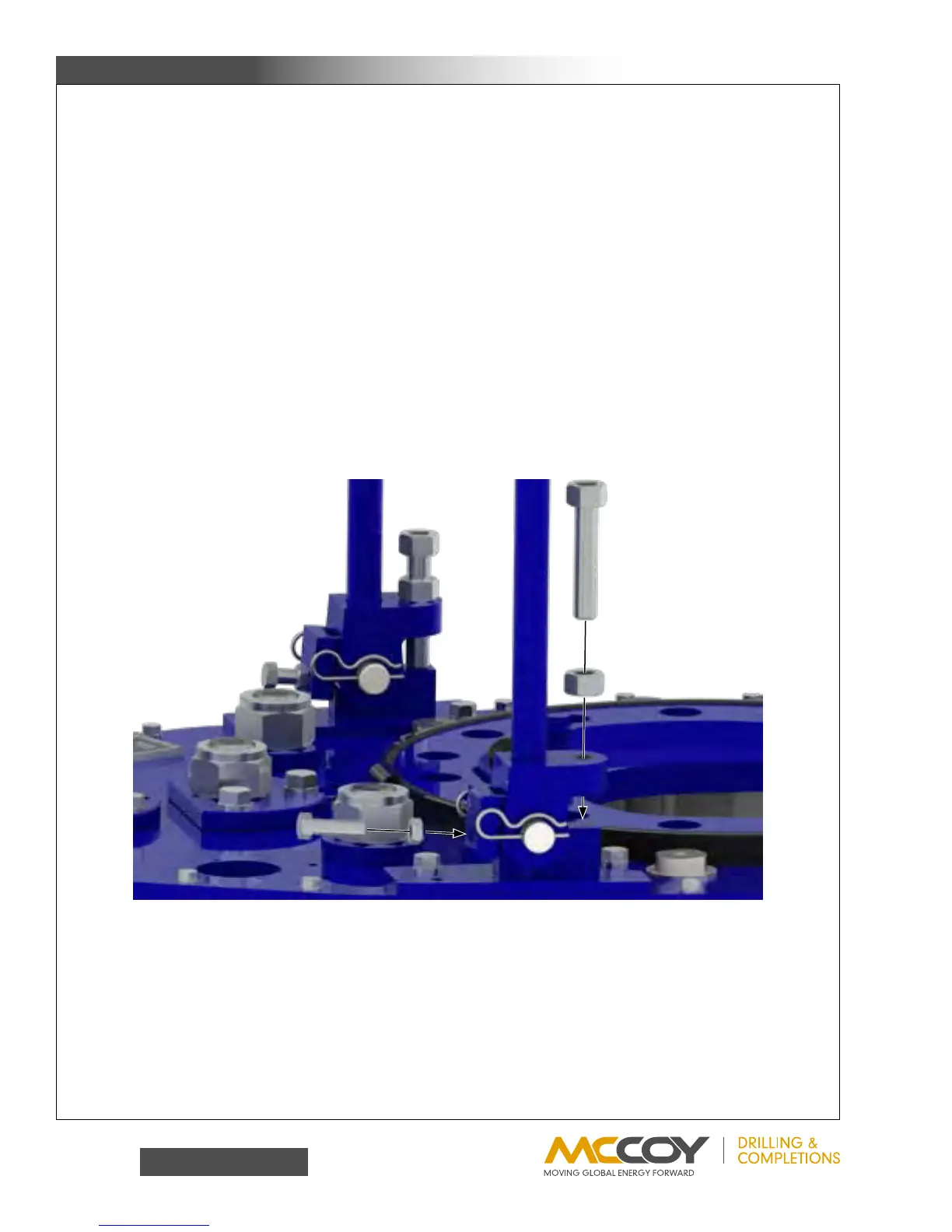

68. Thread1/2”UNChexnutsontotwo1/2”UNCx1-3/4”hexbolts.Threadtheboltsintotherearoftherigidslingweldment

mountingbrackets.(seefollowingillustration).

69. Useacraneandtemporaryslingtohoistthebackupassemblyontoasupportstructurenexttotheassemblylocationofthe

tong.Minimumheightforthebackupsupportsmustbe36”inordertoallowclearanceforinstallingthefrontlegs.

70. Attachtherearlegassemblytothetong:

a. Positionrearlegweldmentonaflatsurfacenearthetongassemblylocation.

● Model80-0420-16usesrearlegweldmentPN101-4487

● Model80-0422usesrearlegweldmentPN101-1547

● Model80-0421-3usesrearlegweldmentPN101-1987

b. Useacranetohoistthetongassemblyofftheassemblysurface.Bringthetongintocontactwiththerearleg,ensuring

thecranecontinuestosupporttheentireweightofthetong.Attachtherearlegweldmenttothetongusingtwo1-1/4”

UNCx8”hexboltsand1-1/4”UNChexnylocknuts,andtwo1”UNCx7”hexboltsand1”UNChexnylocknuts.

Loading...

Loading...