FT-50 Fill Level Inspector Service Manual

1-4

Fill Level Inspection Basics

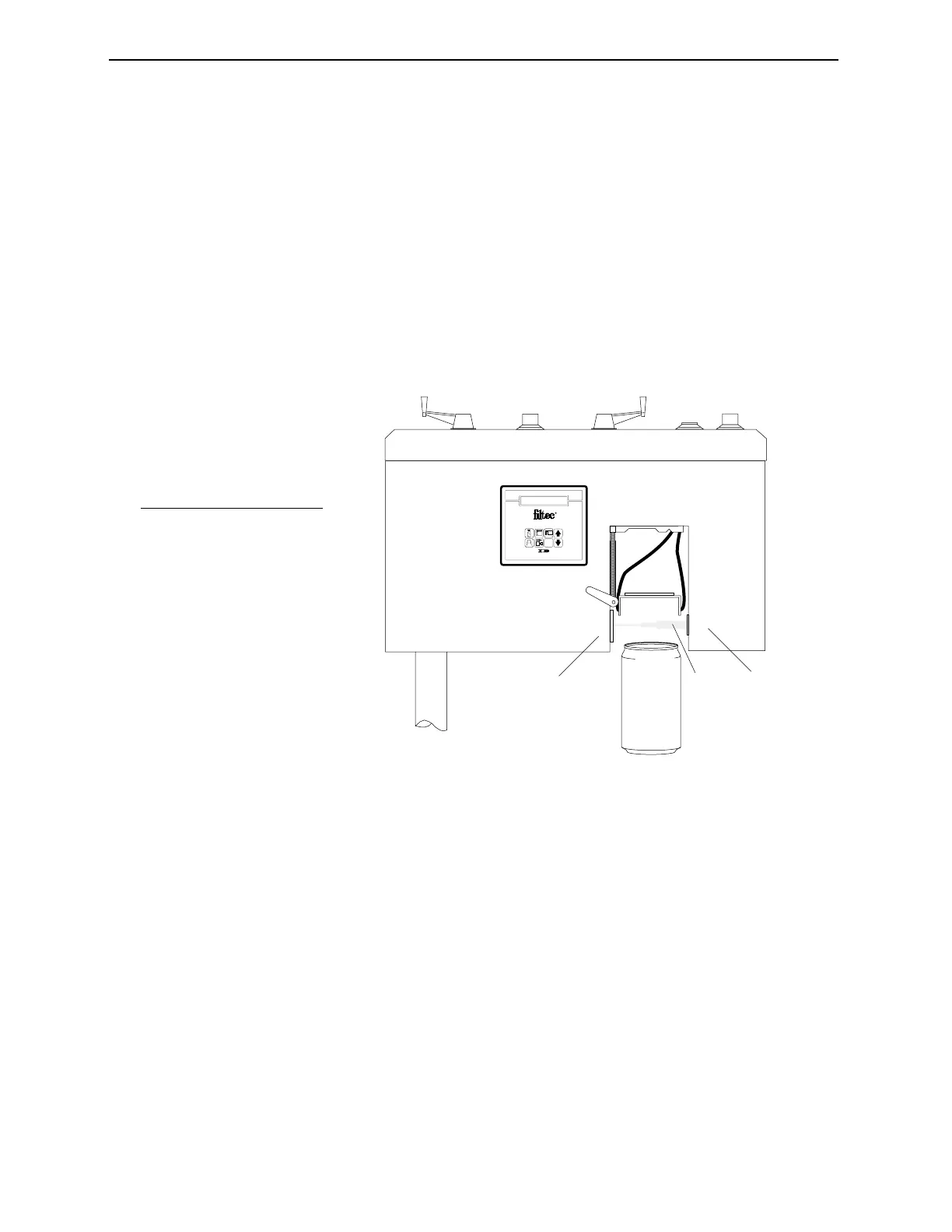

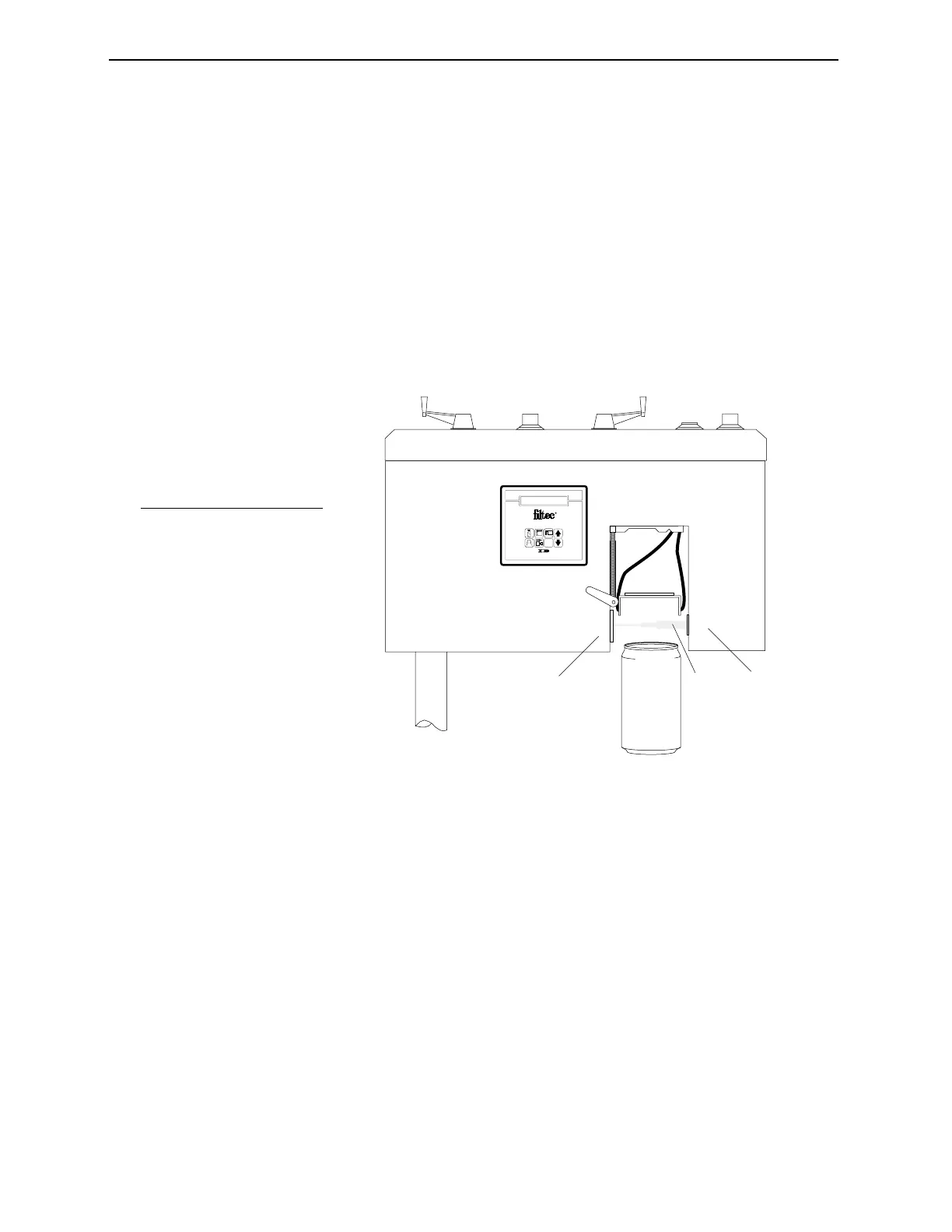

The FT-50 Fill Level Inspection system utilizes a

Container Radiation

Profile Comparison Principle

to create a radiation fingerprint of the

container.

To create a radiation profile a beam of gamma radiation is directed

through the container. Some of the radiation is blocked by the

container material and container’s contents. The remaining

radiation emerges from the opposite side where the amount is

measured by a radiation detector.

Figure 1-2.

Scanning the container.

The amount of radiation measured is the containers radiation

profile, which is then compared against a master profile. Any

container that deviates from the master container profile fails

inspection and is tagged for removal from the production line.

A master container profile is created by scanning several normal

containers— containers that are filled to the proper level. The

average is then calculated and the median container profile is

determined.

?

6

INDUSTRIAL DYNAMICS

Torrance, California USA

MODEL FT-50

FILL LEVEL INSPECTOR

4

3

5

1

2

1

3

2

No. Description

1 Gamma Source

2 Gamma Beam

3 Gamma Detector

Industrial Dynamics Company, Ltd. Document 40255-0600

Loading...

Loading...