Chapter 4: Configuring the FT-50 for Operation

4-3

Chapter Overview

Before you can use your FT-50 Inspection System you must

configure the FT-50 and the rejector to operate on your production

line. There are two parts to configuring the inspection system:

• Mechanical Configuration consists of physically adjusting and

aligning the FT-50 sensors and the rejector.

• Software Configuration consists of activating and setting all

operational parameters for the inspection functions.

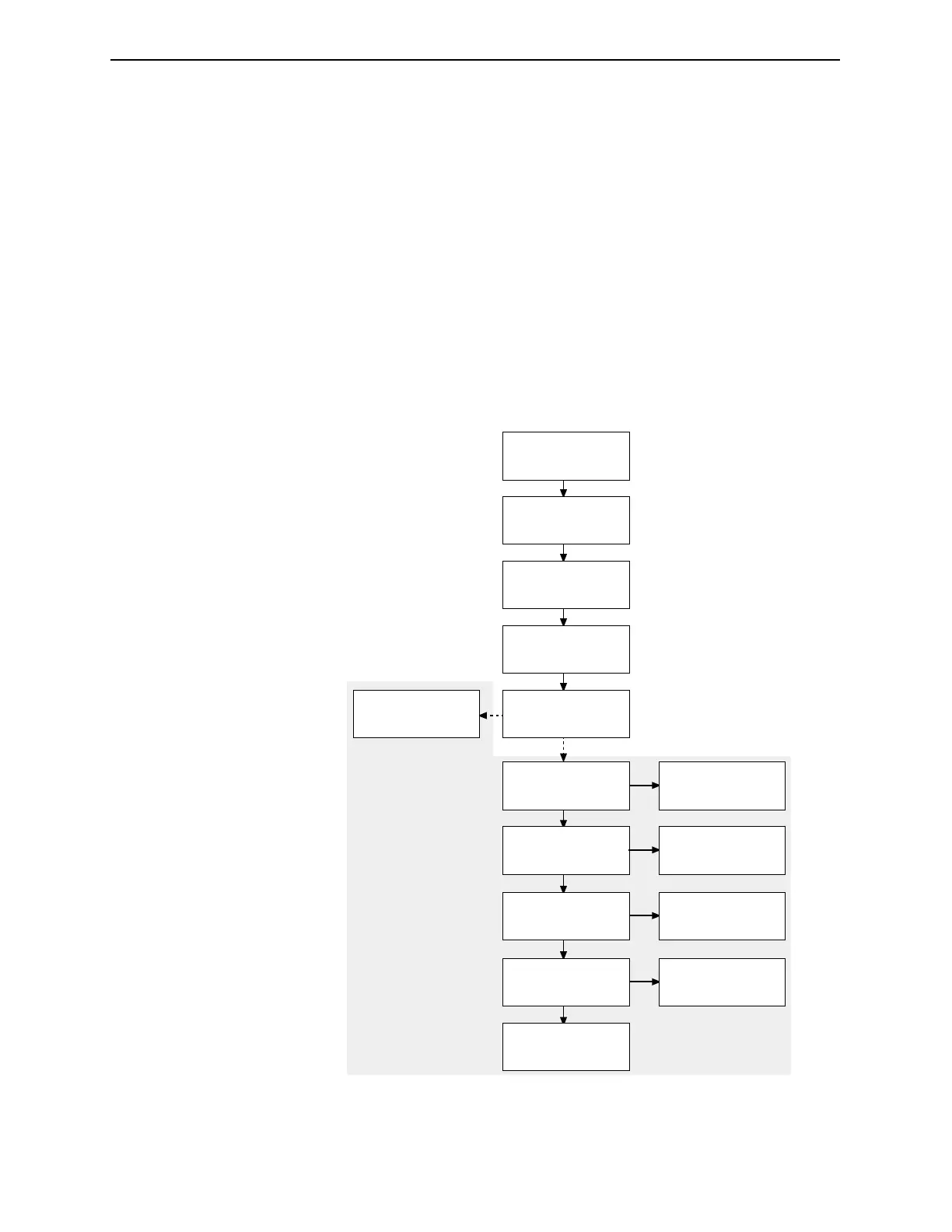

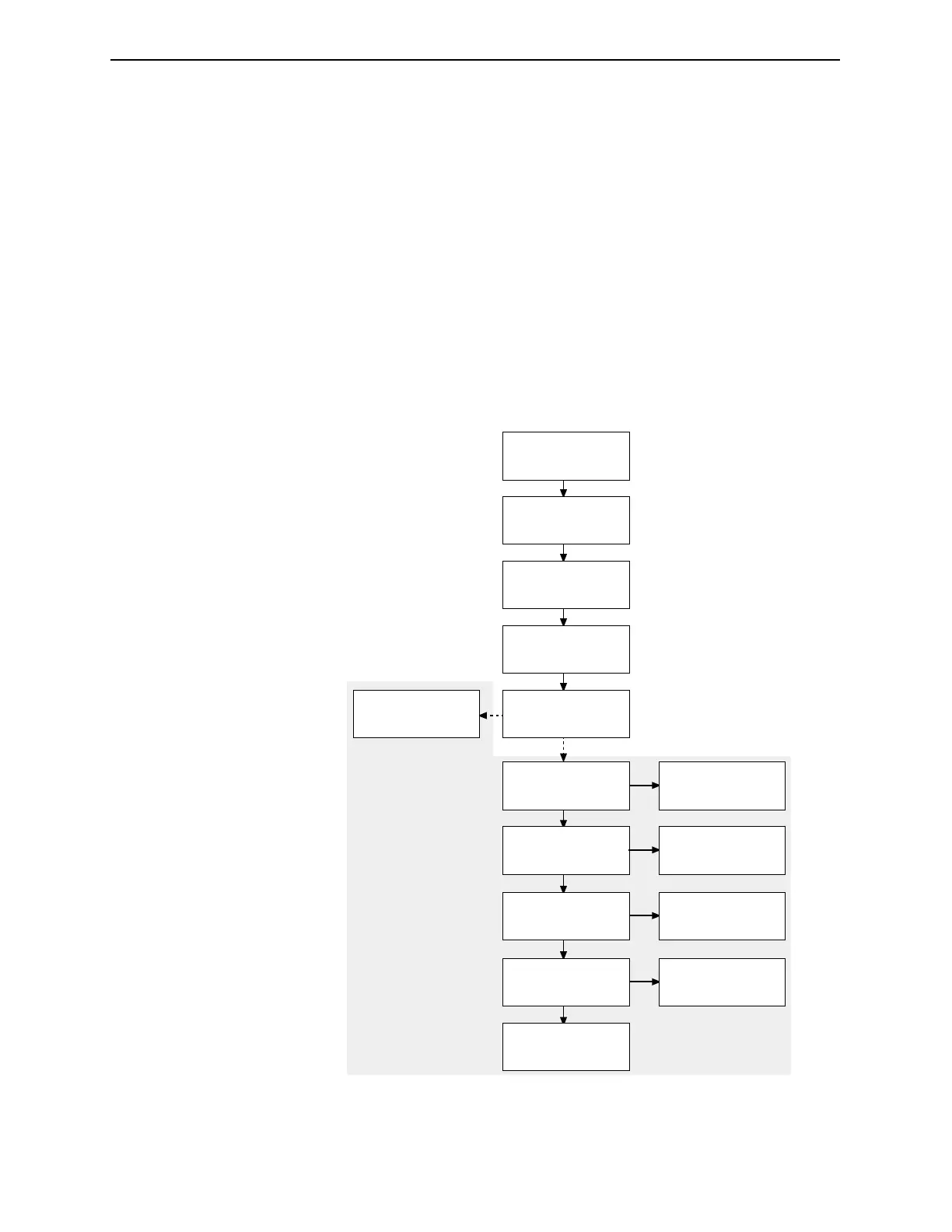

The following flow chart explains the configuration order.

Figure 4-1. FT-50 Inspection System Configuration Flow Chart.

Adjust head height for

fill level inspection.

Adjust inspection

trigger height.

Calibrate encoder

(if applicable) and

rejector timing.

Determine the inspection

looktime gate.

Determine the

gamma threshold.

Perform fill level

optimization, if need.

Configure down can

function.

Configure dud

detection function.

Adjust missing lid sensor.

Adjust bulged

end sensor.

Adjust dud detection

sensor.

Configure external

reject function.

Adjust down can sensor.

Configure bulged

end function.

Configure missing lid

function.

Your FT-50 may not

contain these options.

These procedures apply

only if your FT-50 is so

equipped.

Industrial Dynamics Company, Ltd. Document 40255-0600

Loading...

Loading...