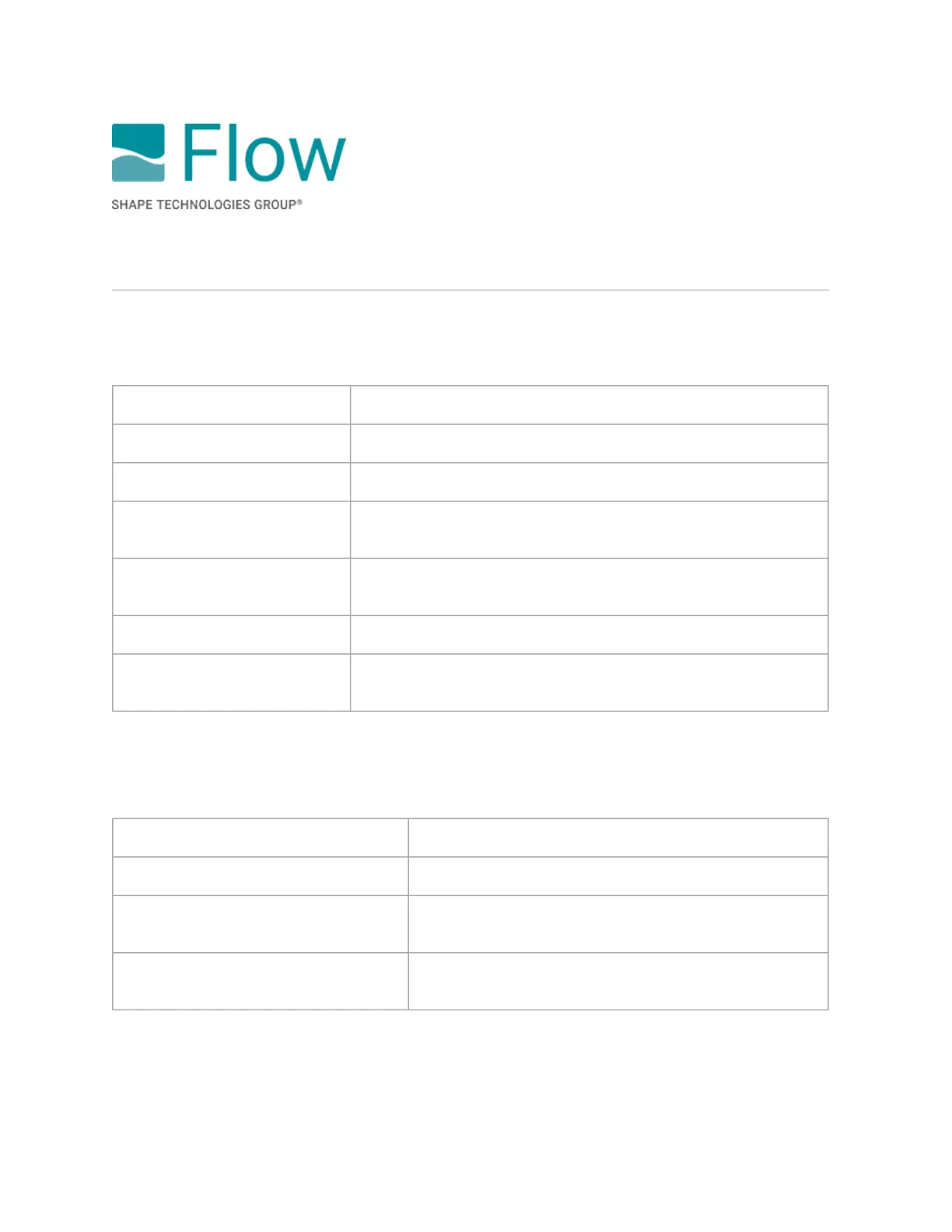

Cut part quality issues

Cutting speed is slower than it should be for a given surface finish and kerf width

Possible cause Solution

Insufficient abrasive flow Make sure the abrasive flow rate is set correctly.

Insufficient water pressure Make sure the pump is providing proper pressure.

Mixing tube standoff is too

great

Check standoff; it should be set to 0.10-in.

Different target material

properties

Check for consistency of target material.

Abrasive is too fine Use a coarser grade of abrasive.

Damaged or worn orifice

Check integrity of the waterjet stream. Inspect orifice; replace if

needed.

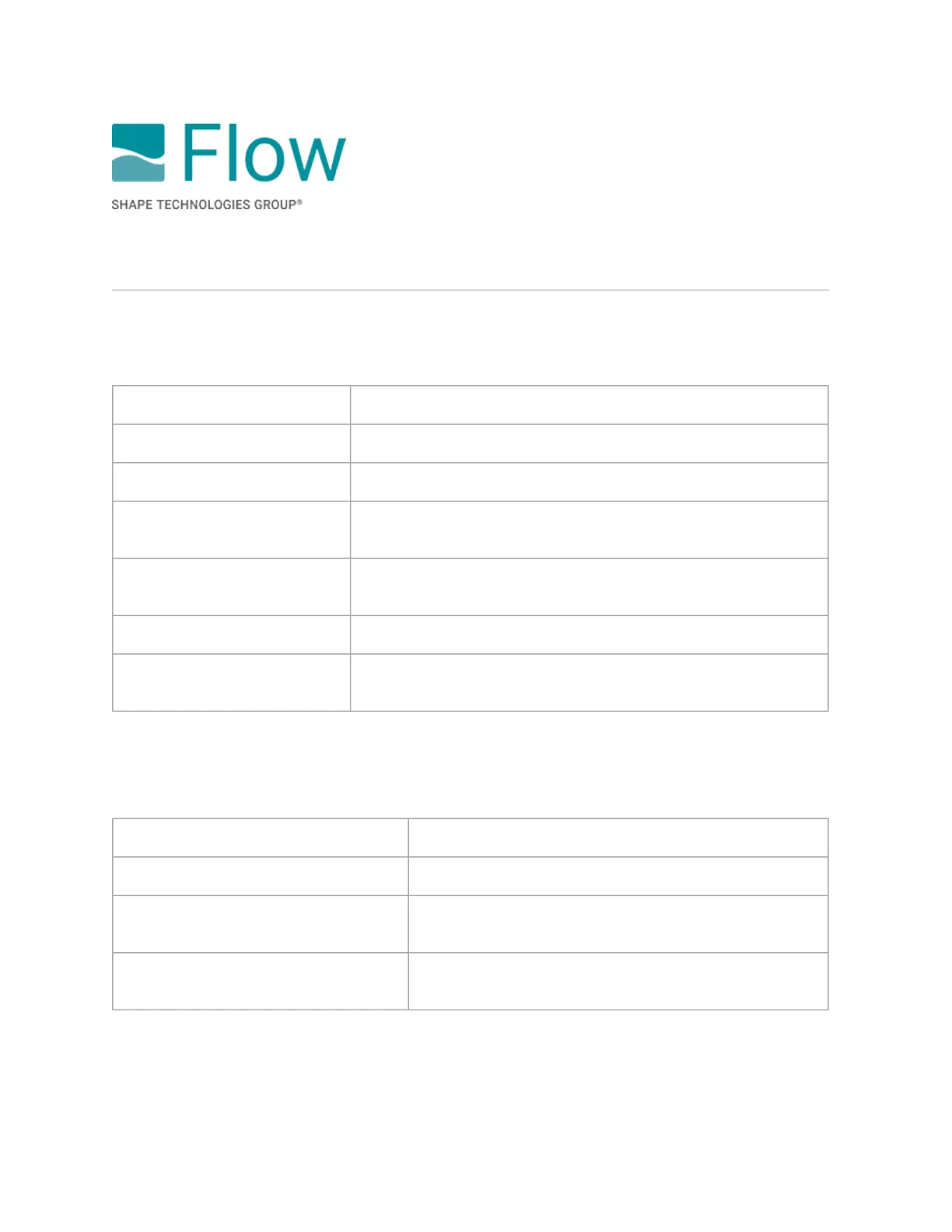

Cutting speed is lower than normal; kerf is too wide

Possible cause Solution

Mixing tube standoff is too great Check standoff; it should be set to 0.10-in.

Mixing tube's ID is too large or the

mixing tube is worn out

Make sure that the correct size mixing tube is installed.

Replace worn mixing tubes.

Damaged or worn orifice

Check for a flaring waterjet stream. Inspect orifice;

replace if needed.

© 2021 Flow International Corp.

Retrieved from Flow KB on April 13, 2021 PST

Loading...

Loading...