Materials and fixtures

Material flatness is key

The most important requirement for the target material is that it be flat (parallel) with respect to the

catcher top (which should be parallel to the XY plane).Watch out for material that has a flat surface, but

is tilted up on a corner or side or warped material that might touch the catcher top on the edges, but the

center is warped up.

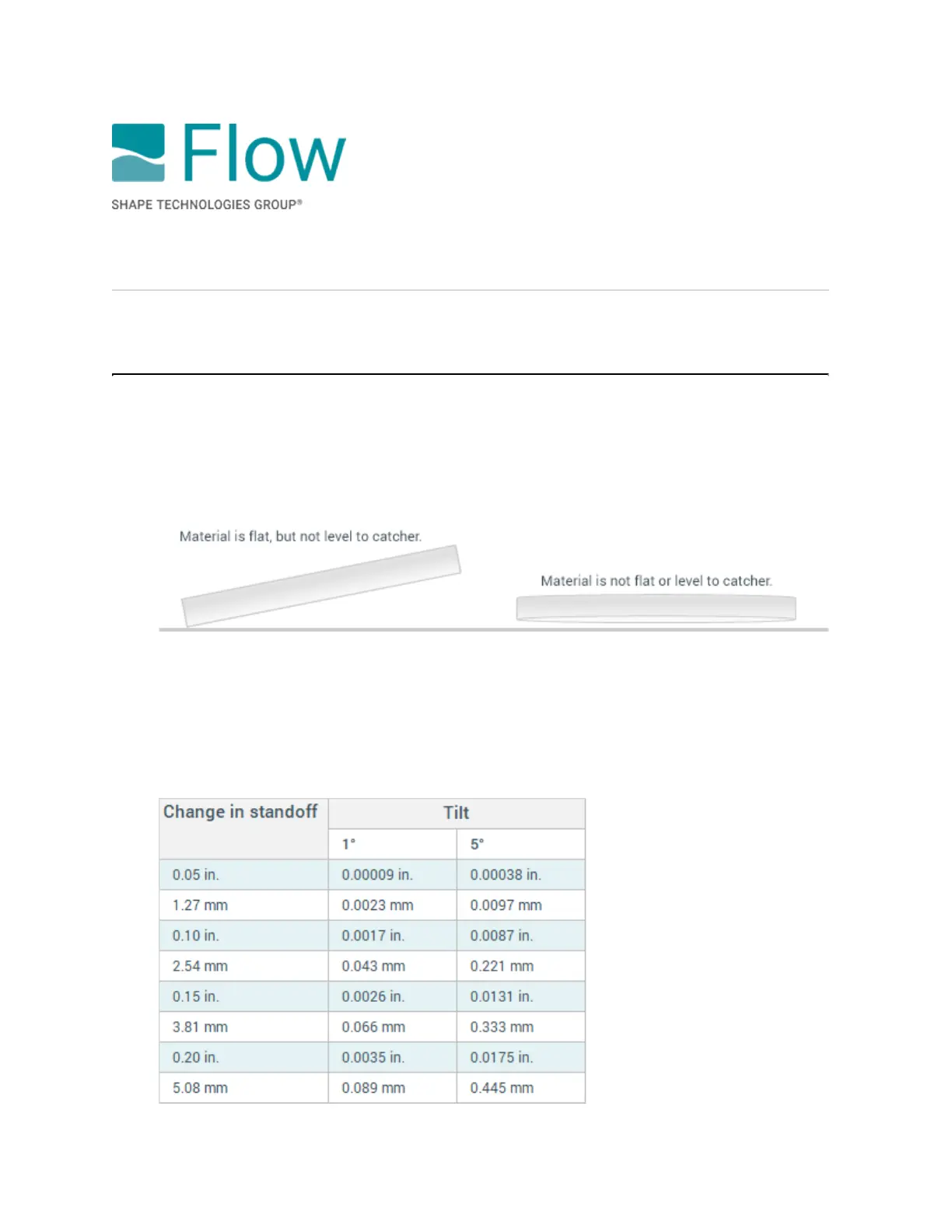

Non-flat material affects standoff and cutting accuracy. How much error will result from non-flat material

is directly related to the tilt applied by FlowCut, and the change from programmed standoff. Standoff is

directly related to the flatness of the material, and part accuracy will be affected as the material

approaches or recedes from the mixing tube tip.

Table 1. Typical errors in part accuracy that can be expected from problems in material flatness.

© 2021 Flow International Corp.

Retrieved from Flow KB on April 13, 2021 PST

Cutting with Dynamic Waterjet

Loading...

Loading...