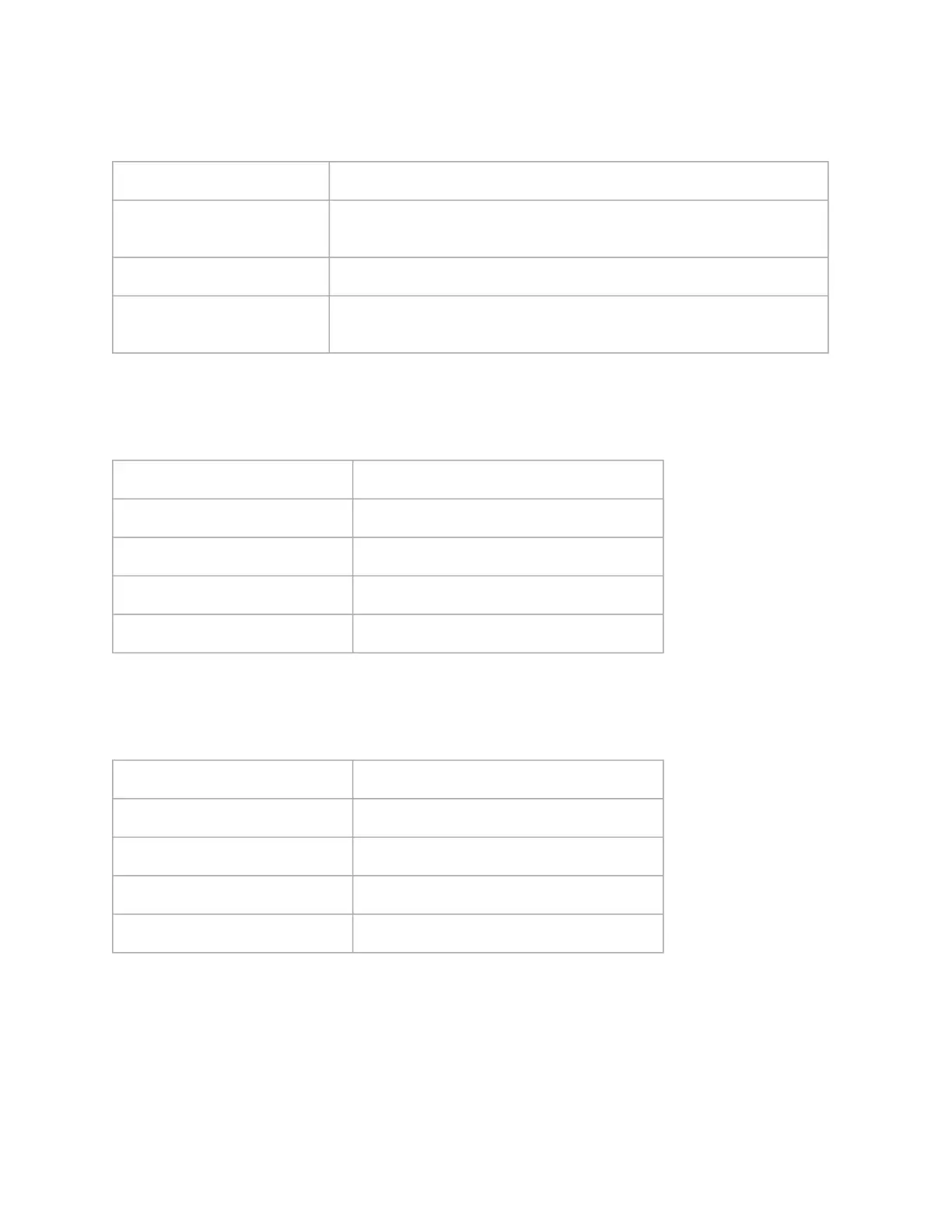

Inconsistent kerf width

Possible cause Solution

Inconsistent abrasive flow

rate

Metering disk may be too large. Change disk and/or reduce cutting

speed.

Inconsistent water pressure Check for steady water pressure; correct any pump problems.

Inconsistent material being

cut

Check material.

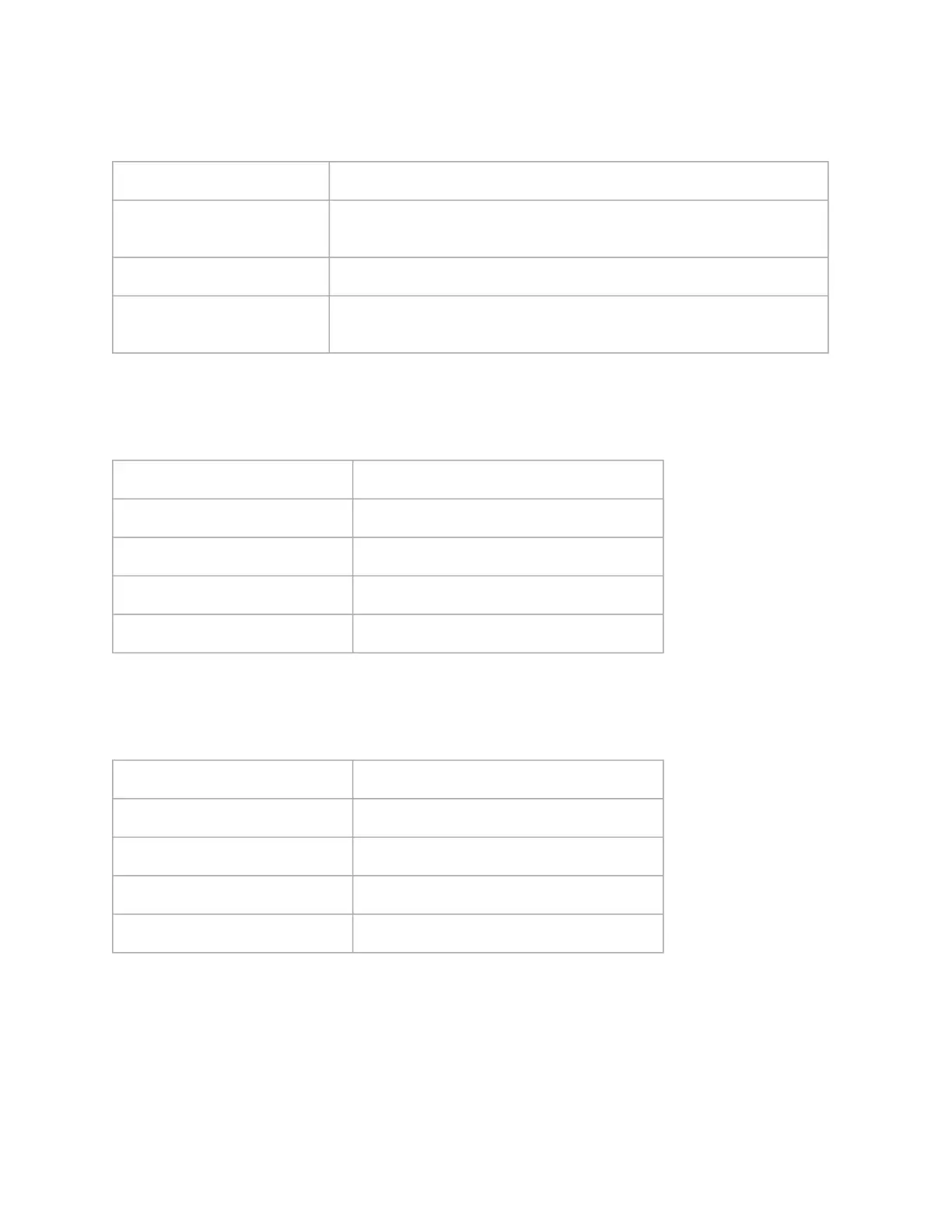

Kerf has pronounced "V" shape

Possible cause Solution

Cutting speed is too fast Reduce cutting speed.

Mixing tube standoff is too great Check standoff; it should be set to 0.10-in.

Abrasive flow rate is too low Increase abrasive flow rate.

Water pressure is too low Increase water pressure.

Rough surface finish

Possible cause Solution

Cutting speed is too fast Reduce cutting speed.

Mixing tube standoff is too great Check standoff; it should be set to 0.10-in.

Abrasive is too coarse Use a finer grade of abrasive.

Damaged or worn orifice Inspect orifice; replace if needed.

© 2021 Flow International Corp.

Retrieved from Flow KB on April 13, 2021 PST

Loading...

Loading...