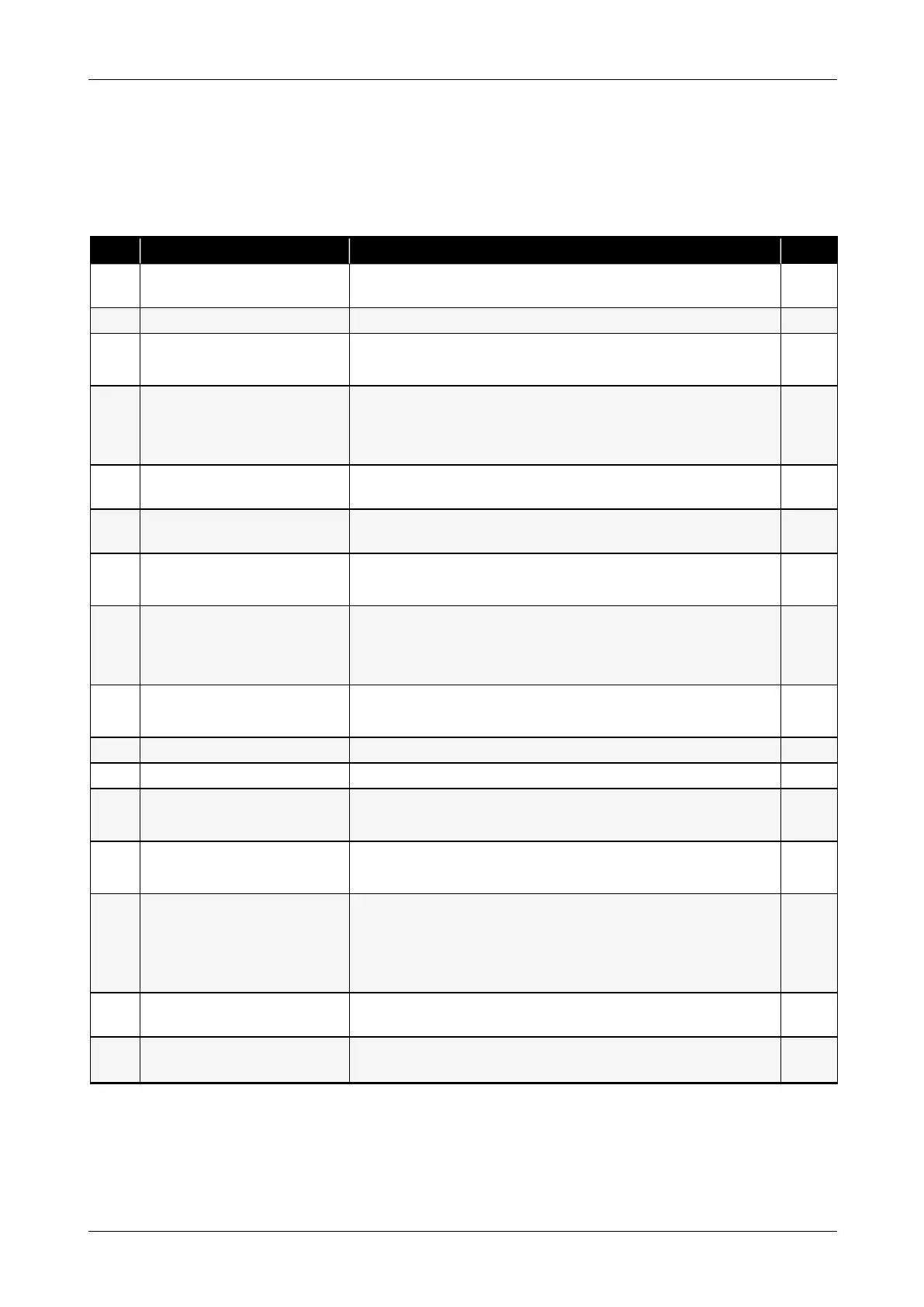

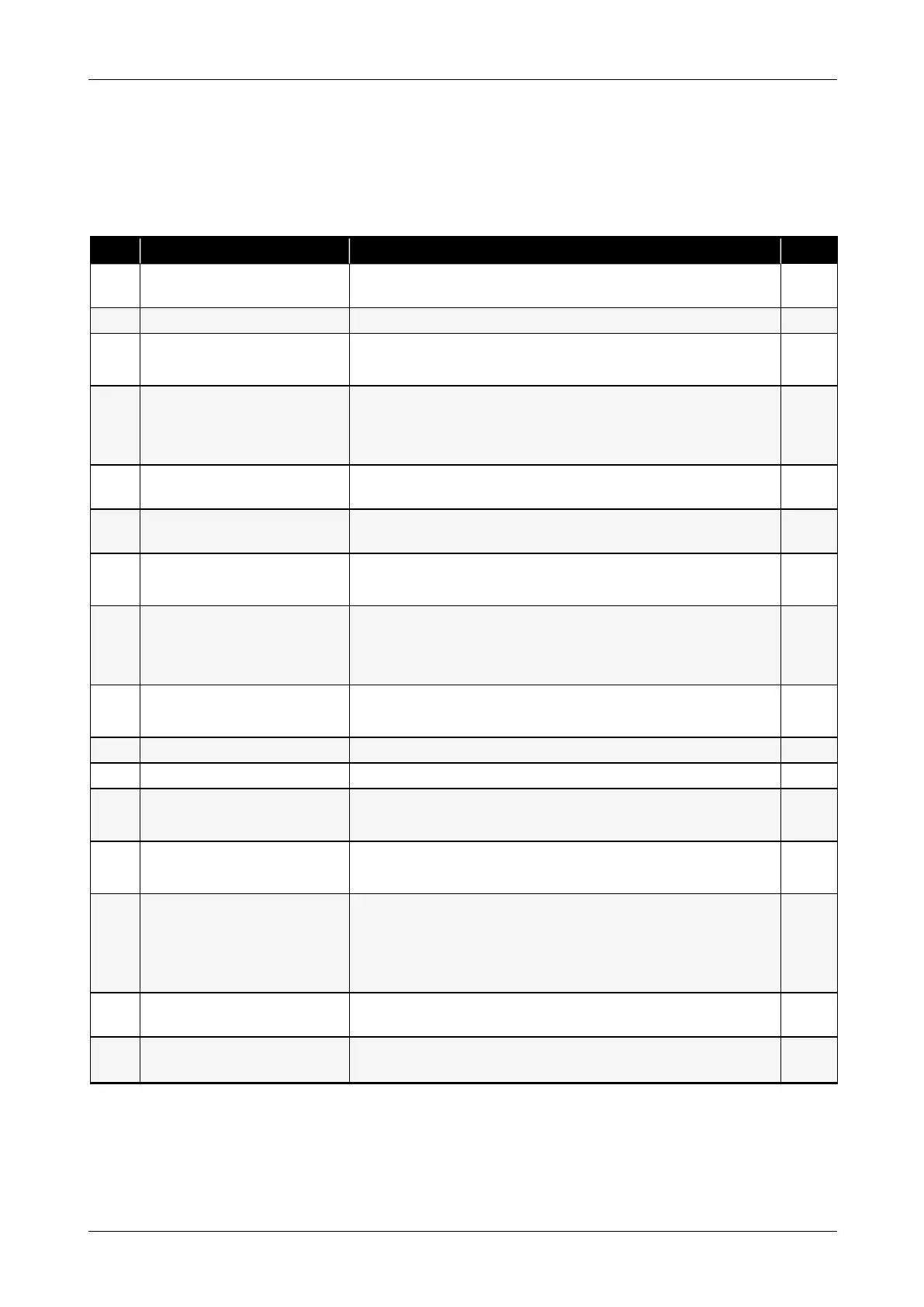

5.2 DAILY CHECKS

Perform the following checks before putting the unit into operational service and before

each operational day.

Table 2 - Daily checks

Item Check Further action ✔ /✘

1

Nuts, bolts and washers

secure

Visual check of all nuts, bolts, and washers for security

o

2

Check the reflectors All reflectors fitted and undamaged

o

3

Check the tow hitch

assembly

l

Wear indicator OK when connected

l

Brake away cable condition

o

4

Check the handbrake

lever

Operates correctly

Holds machine when applied

If faulty, contact an agent

o

5

Check the jockey wheel

assembly

Free to operate correctly

o

6

Check the lighting cable

and adaptor

Undamaged

o

7

Check all fluid levels

l

Engine oil

l

Hydraulic oil

o

8

Proximity sensors are not

damaged and work

correctly

l

Bonnet

l

Hopper tray

l

Stop bar

o

9

Discharge chute

l

Chute clamps – function and security

l

Deflector handle – fitted and secure

o

10

Throttle Tight enough to hold maximum RPM

o

11

Fuel tank Fuel level and free from debris inside

o

12

Check the stop bar

l

Free to operate

l

Feed rollers stop when pressed

o

13

Check the E-Stop (if

fitted)

l

Free to operate

l

Feed rollers or engine stop when pressed

o

14

Check the hopper tray

buttons

l

Free from damage

l

Function correctly

►

For more information, refer to "Safety &

function test" on page 63

o

15

Feed roller function Feed rollers operate backwards and forwards at

maximum RPM

o

16

Check the hopper tray

catches

Secure hopper tray

o

Chapter 5: Maintenance

Redwood Global Ltd - ST6P

Operator and Maintenance Manual

73 12-00-001 v4.0

Loading...

Loading...