Special care of O-

rings

IMPORTANT! When replacing O-rings, grease the new O-ring before fitting it.

When repeatedly connecting and disconnecting the coolant hoses on the torch hosep-

ack, grease the O-rings regularly.

Unless a special grease is specified for the O-rings, use the O-ring grease from Fronius

with item number 40,0009,0044.

Whenever the

welding torch or

torch hosepack is

changed

Whenever the welding torch or torch hosepack is changed, ensure that the coupling

point is clean and dry. Remove any coolant that has escaped from the coupling point.

Every 6 months

CAUTION!

Danger of damage to electronic components.

▶

Do not bring the air nozzle too close to electronic components.

- Open covers, remove device side panels and clean inside of device with dry

reduced compressed air. After cleaning, restore device to its original state.

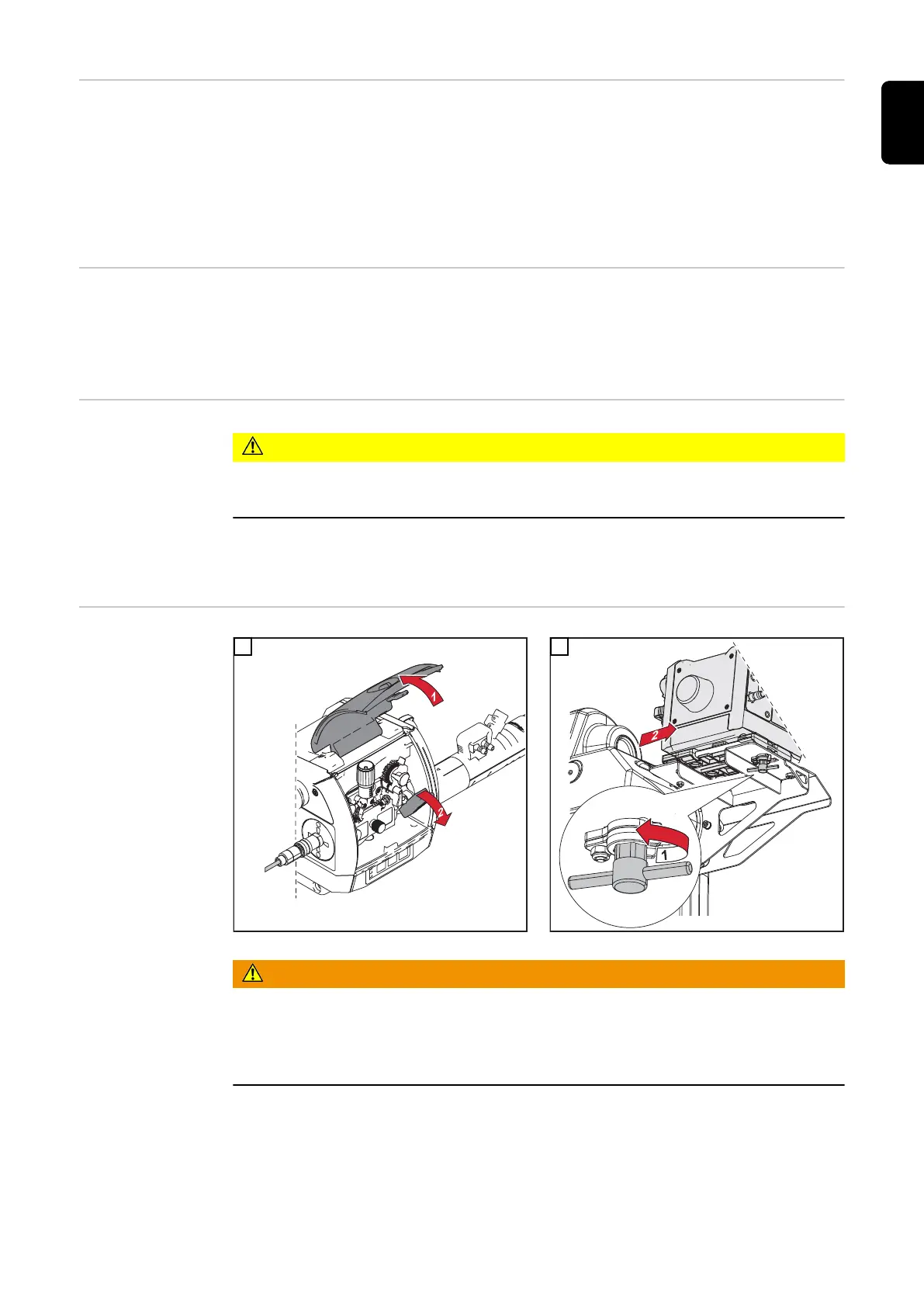

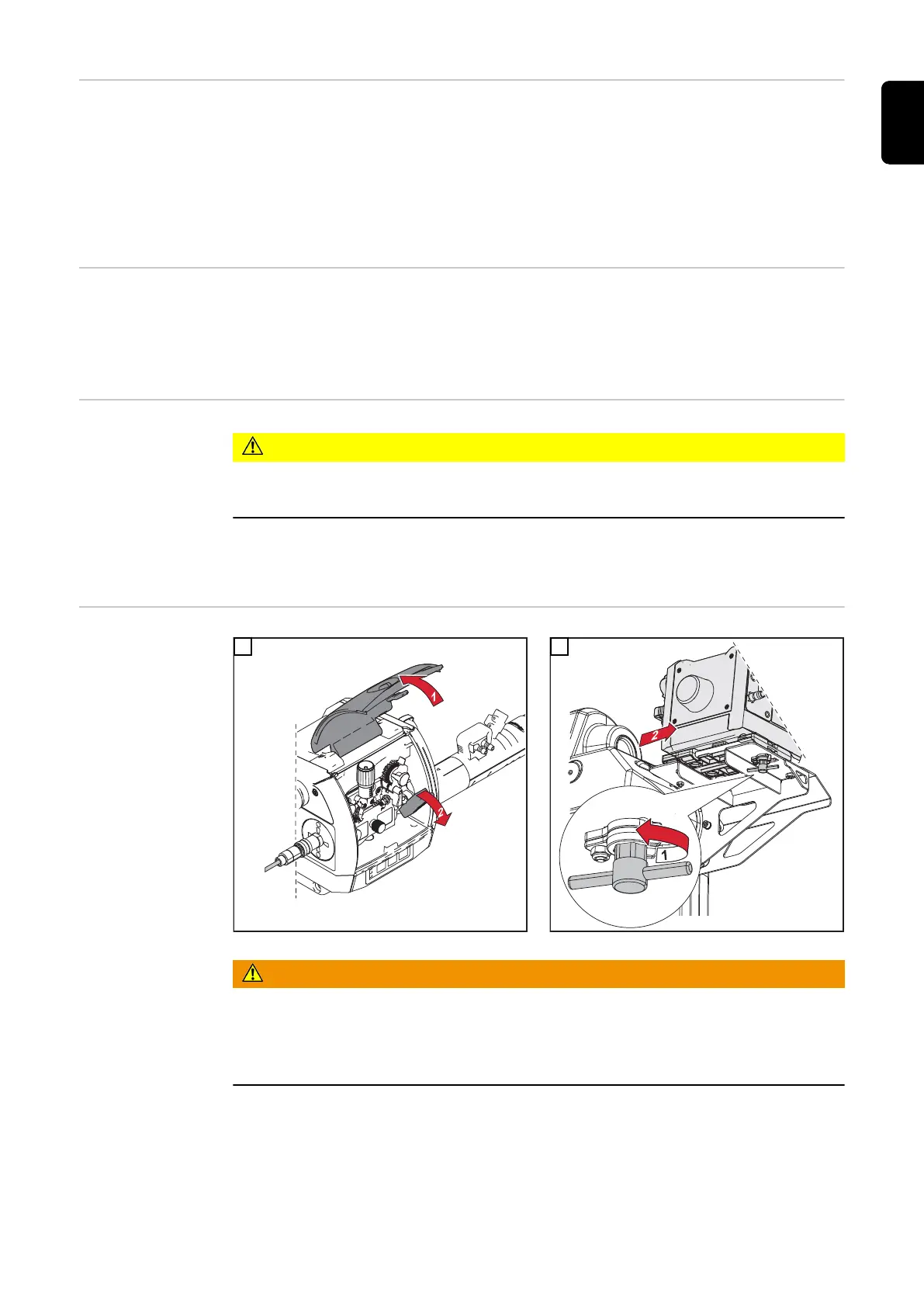

Preparing the WF

15i/25i/30i R PAP

for replacement

of the welding

torch inner liner

1 2

WARNING!

Toppling or falling devices can cause life-threatening injuries.

Robot movements may not take place until:

▶

The wirefeeder has been retracted and locked

▶

All cables, leads and hosepacks are securely connected to the wirefeeder

125

EN

Loading...

Loading...