56

Always choose the stick out of the welding torch relative to the workpiece so that the dis-

tance arrow stays green and the torch tip is always inside the target circle.

Rod electrode

tasks

The following tasks are available for the rod electrode welding process:

Speed / Stick out / Po-

sition

In addition to the welding speed and stick out, the trainee also practises guiding the weld-

ing torch with the torch in the correct position. If the welding torch points upwards too

much, a red direction arrow (GHOST) points downwards or vice versa. A cross indicates

the optimum welding torch position.

- Green: optimum position

- Yellow: within the tolerance

- Red: outside the tolerance - requires correction!

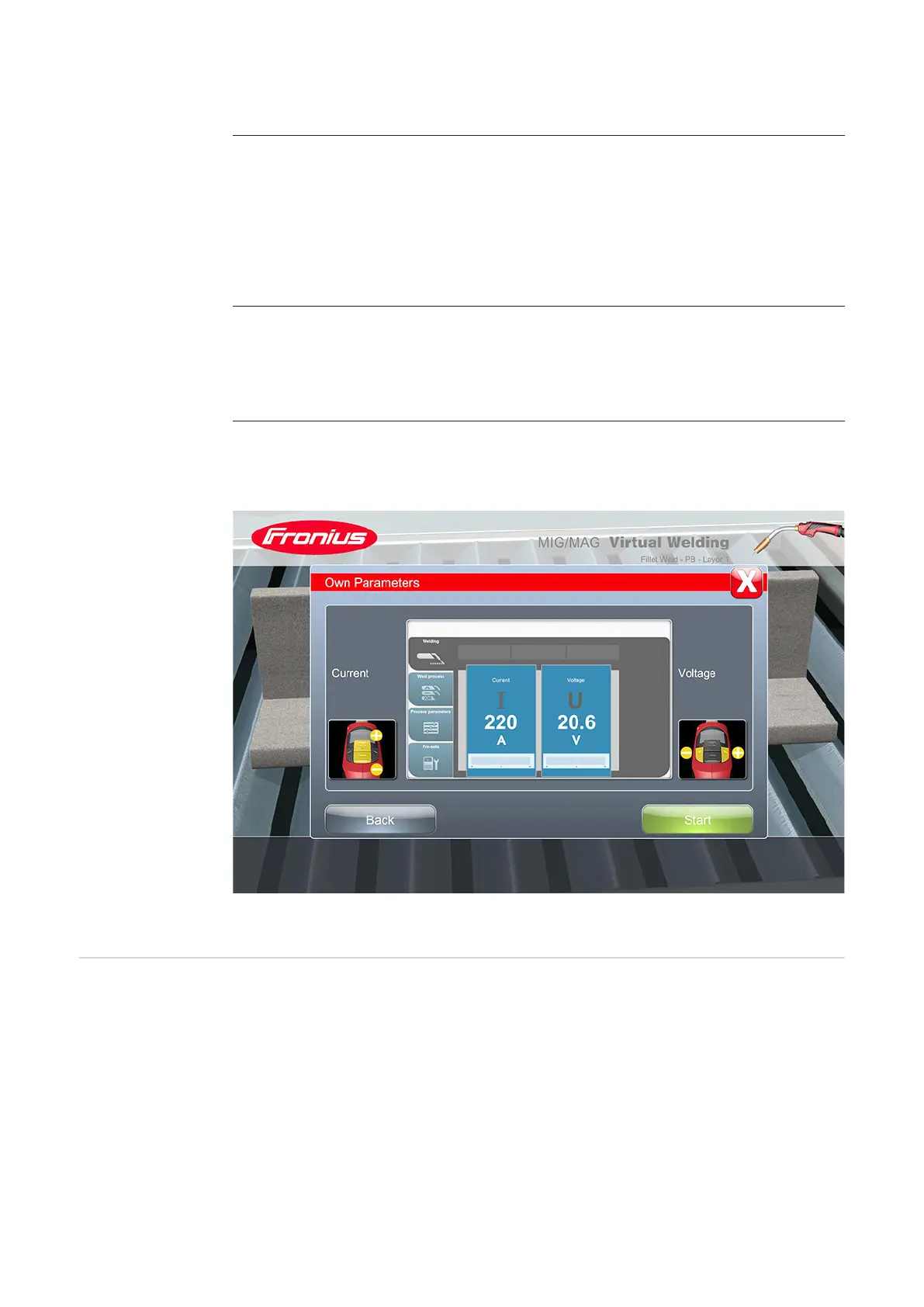

Simulation with fixed

parameters

The simulation provides a representation of real welding, with visualisation of the arc and

of the formation of the weld seam. The welding parameters of wire speed, amperage and

voltage are pre-set for this task. The trainee guides the welding torch freely, without re-

ceiving any guidance.

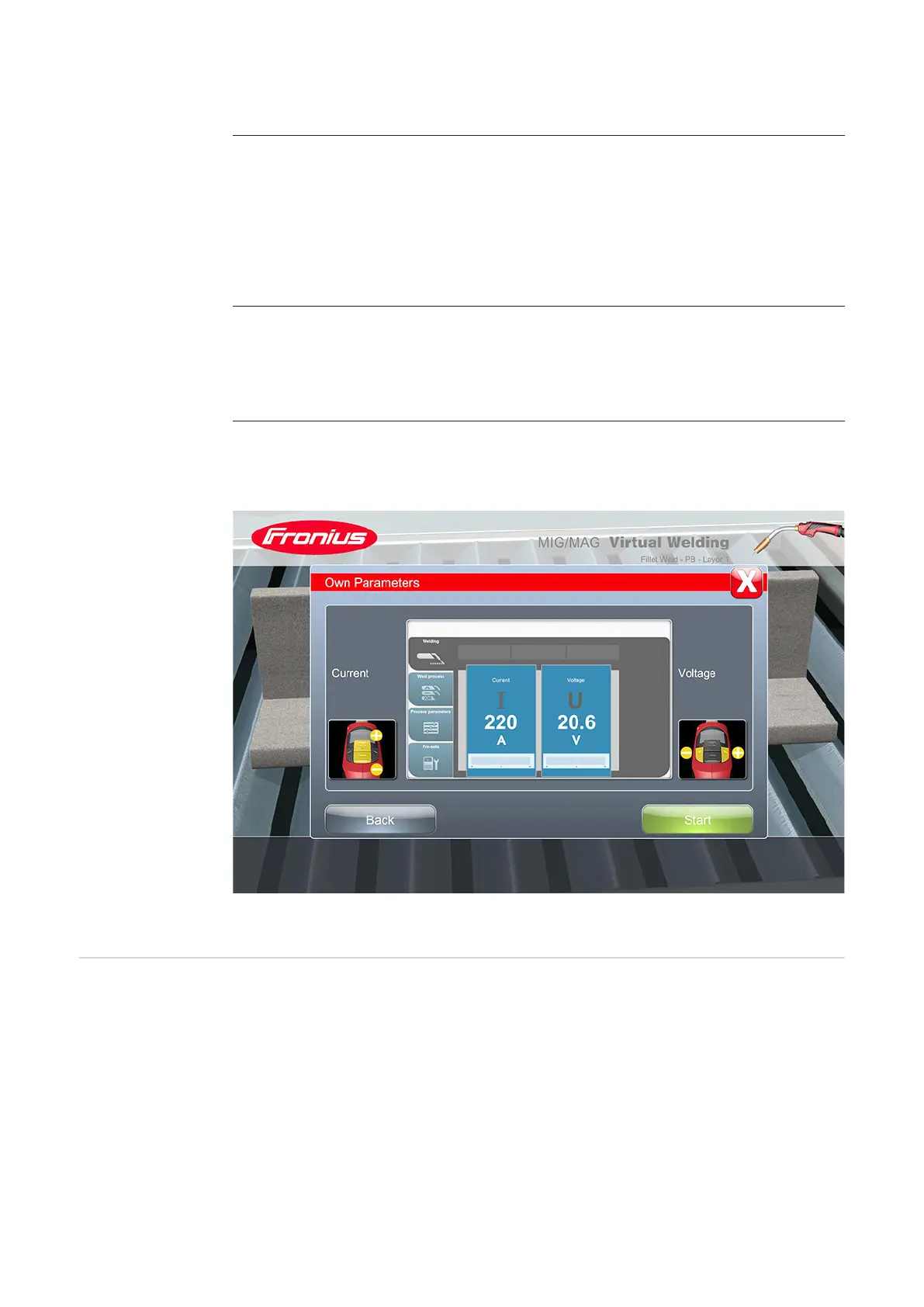

Simulation with varia-

ble parameters

For the welding parameters of welding voltage and welding current, the trainee sets the

appropriate values for the task on the JobMaster welding torch.

The trainee guides the welding torch freely, without being guided by a target object.

Loading...

Loading...